- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

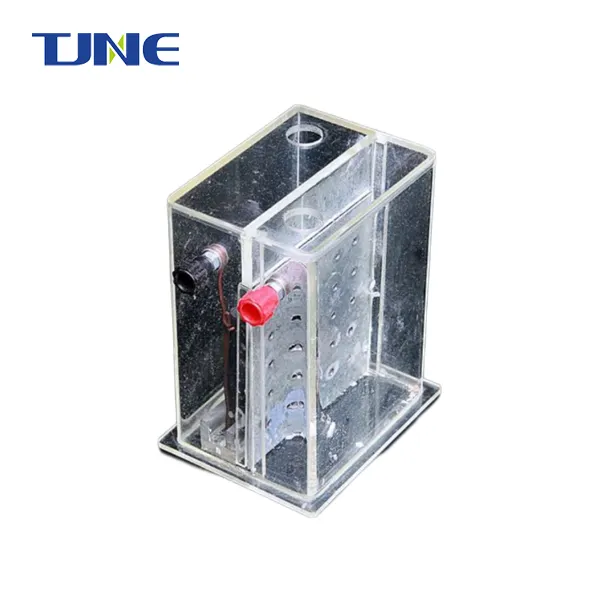

Electrolysis is a crucial process in various industries, from water treatment to metal production. When it comes to choosing the right materials for electrodes, titanium has emerged as a popular choice, particularly in the form of RUTHENIUM IRIDIUM COATED TITANIUM ANODES. But is titanium truly good for electrolysis? To answer this question, we need to delve into the properties of titanium and its coated variants, exploring their advantages, comparisons with other materials, and specific applications.

What are the advantages of using RUTHENIUM IRIDIUM COATED TITANIUM ANODES?

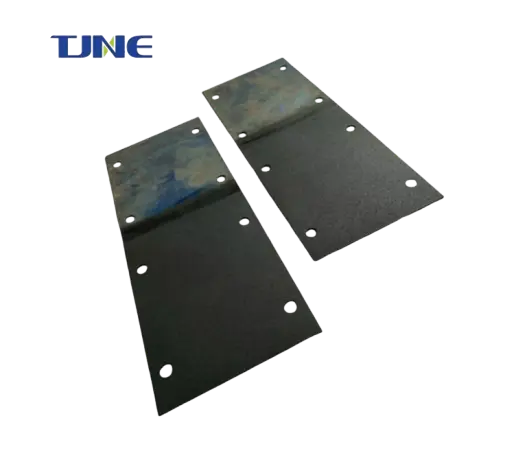

RUTHENIUM IRIDIUM COATED TITANIUM ANODES offer a unique combination of properties that make them exceptionally well-suited for electrolysis applications. These anodes leverage the inherent strengths of titanium while enhancing its performance through advanced coating technology.

First and foremost, titanium itself possesses excellent corrosion resistance, which is crucial in the harsh chemical environments often encountered in electrolysis processes. The metal forms a stable oxide layer on its surface, protecting it from further degradation. This natural resistance is further amplified by the ruthenium-iridium coating, creating an electrode that can withstand even the most aggressive electrolytes.

The coating of ruthenium and iridium on titanium substrates brings several additional benefits. Ruthenium and iridium are both platinum group metals known for their catalytic properties. When applied to titanium, they significantly lower the overpotential required for various electrochemical reactions. This reduction in overpotential translates to improved energy efficiency, allowing electrolysis processes to occur at lower voltages and consuming less power.

Moreover, the ruthenium-iridium coating enhances the electrode's conductivity. While titanium is a good conductor, the addition of these noble metals further improves its ability to transfer electrons, leading to more efficient electrolysis. This increased conductivity also contributes to a more uniform current distribution across the electrode surface, ensuring consistent performance and product quality.

Another significant advantage of RUTHENIUM IRIDIUM COATED TITANIUM ANODES is their longevity. The combination of titanium's durability and the protective nature of the coating results in electrodes that can withstand prolonged use in industrial settings. This extended lifespan reduces the frequency of electrode replacements, minimizing downtime and maintenance costs for electrolysis operations.

The dimensional stability of these anodes is also noteworthy. Unlike some electrode materials that may deform or erode over time, RUTHENIUM IRIDIUM COATED TITANIUM ANODES maintain their shape and size throughout their operational life. This stability is crucial for maintaining consistent electrolysis conditions and product quality, especially in precision applications.

Lastly, these anodes offer versatility in terms of customization. The coating process can be fine-tuned to optimize the electrode for specific electrolysis applications. By adjusting the composition and thickness of the ruthenium-iridium coating, manufacturers can tailor the anodes to meet the unique requirements of different industries and processes.

How do RUTHENIUM IRIDIUM COATED TITANIUM ANODES compare to other electrode materials?

When evaluating electrode materials for electrolysis, it's essential to compare RUTHENIUM IRIDIUM COATED TITANIUM ANODES with other options to understand their relative strengths and limitations. This comparison helps in making informed decisions for specific applications.

One common alternative is graphite electrodes. While graphite is relatively inexpensive and has good conductivity, it lacks the corrosion resistance of titanium-based anodes. In aggressive environments, graphite electrodes can deteriorate rapidly, leading to frequent replacements and potential contamination of the electrolyte. RUTHENIUM IRIDIUM COATED TITANIUM ANODES, on the other hand, offer superior longevity and maintain the purity of the electrolysis process.

Platinum electrodes are another high-performance option. They exhibit excellent catalytic properties and corrosion resistance. However, the high cost of platinum makes it prohibitively expensive for large-scale industrial applications. RUTHENIUM IRIDIUM COATED TITANIUM ANODES provide a more cost-effective solution while still offering many of the benefits associated with noble metal electrodes.

Lead dioxide electrodes have been used in certain electrolysis applications, particularly in the production of chlorine and sodium hypochlorite. While they are relatively inexpensive, concerns about lead contamination and environmental impact have led to a shift away from these electrodes in many industries. RUTHENIUM IRIDIUM COATED TITANIUM ANODES offer a safer and more environmentally friendly alternative without compromising on performance.

Stainless steel electrodes are sometimes used in less demanding electrolysis applications. While they offer good corrosion resistance in mild conditions, they cannot match the performance of RUTHENIUM IRIDIUM COATED TITANIUM ANODES in more aggressive environments. The titanium-based anodes provide superior resistance to chlorides and other corrosive substances commonly encountered in industrial electrolysis.

In terms of energy efficiency, RUTHENIUM IRIDIUM COATED TITANIUM ANODES generally outperform most alternatives. The catalytic properties of the ruthenium-iridium coating reduce the overpotential required for electrolysis reactions, leading to lower energy consumption compared to uncoated electrodes or those made from less catalytically active materials.

When considering the total cost of ownership, RUTHENIUM IRIDIUM COATED TITANIUM ANODES often prove to be the most economical choice for many applications. While their initial cost may be higher than some alternatives, their long lifespan, low maintenance requirements, and energy efficiency result in significant cost savings over time.

What applications benefit most from RUTHENIUM IRIDIUM COATED TITANIUM ANODES?

The unique properties of RUTHENIUM IRIDIUM COATED TITANIUM ANODES make them particularly well-suited for a wide range of electrolysis applications across various industries. Understanding these applications helps highlight the versatility and importance of these advanced electrodes.

Water treatment is one of the primary areas where RUTHENIUM IRIDIUM COATED TITANIUM ANODES excel. In electrochlorination systems, these anodes are used to produce chlorine and sodium hypochlorite directly from saltwater or brine solutions. The corrosion resistance of titanium, combined with the catalytic properties of the ruthenium-iridium coating, ensures efficient and long-lasting performance in these systems. This application is crucial for water disinfection in municipal water treatment plants, swimming pools, and industrial cooling systems.

The chlor-alkali industry, which produces chlorine, sodium hydroxide, and hydrogen through the electrolysis of brine, is another major beneficiary of RUTHENIUM IRIDIUM COATED TITANIUM ANODES. The demanding nature of this process, involving high current densities and corrosive environments, makes these anodes an ideal choice. Their stability and efficiency contribute to improved product quality and reduced energy consumption in chlor-alkali plants.

In the field of metal recovery and refining, RUTHENIUM IRIDIUM COATED TITANIUM ANODES play a vital role. Electrowinning processes, used to extract metals like copper, zinc, and nickel from their ores, benefit from the durability and consistent performance of these anodes. The ability to withstand aggressive electrolytes and maintain dimensional stability ensures high-quality metal production with minimal impurities.

The production of strong oxidizers, such as sodium perchlorate, is another application where RUTHENIUM IRIDIUM COATED TITANIUM ANODES shine. These processes often involve highly corrosive conditions that would quickly degrade less resistant electrode materials. The superior corrosion resistance and catalytic activity of ruthenium-iridium coated anodes enable efficient and safe production of these important chemical compounds.

In the realm of environmental protection, these anodes are increasingly used in advanced oxidation processes for wastewater treatment. Their ability to generate powerful oxidizing species directly in the water helps break down recalcitrant organic pollutants, pharmaceuticals, and other contaminants that are difficult to remove through conventional treatment methods.

The cathodic protection industry also benefits from RUTHENIUM IRIDIUM COATED TITANIUM ANODES. These anodes are used in impressed current cathodic protection systems to prevent corrosion of metal structures such as pipelines, storage tanks, and offshore platforms. Their long lifespan and stable performance make them an excellent choice for these critical protection systems.

In conclusion, titanium, especially in the form of RUTHENIUM IRIDIUM COATED TITANIUM ANODES, proves to be an excellent material for electrolysis across a wide range of applications. Its combination of corrosion resistance, catalytic activity, and long-term stability addresses many of the challenges faced in industrial electrolysis processes. While the initial investment in these anodes may be higher than some alternatives, their superior performance, energy efficiency, and longevity often result in significant long-term benefits. As industries continue to seek more efficient and sustainable solutions, RUTHENIUM IRIDIUM COATED TITANIUM ANODES are likely to play an increasingly important role in the future of electrolysis technology.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

2. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/RuO2–Sb2O5–SnO2 electrodes for O2 evolution. The Journal of Physical Chemistry B, 105(20), 4623-4628.

3. Kraft, A. (2007). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.

4. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

5. Comninellis, C., & Chen, G. (Eds.). (2010). Electrochemistry for the Environment. Springer Science & Business Media.

6. Karlsson, R. K., & Cornell, A. (2016). Selectivity between oxygen and chlorine evolution in the chlor-alkali and chlorate processes. Chemical Reviews, 116(5), 2982-3028.

7. Sequeira, C. A. C. (2018). Environmental Oriented Electrochemistry. Elsevier.

8. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

9. Xu, L., & Xiao, Y. (2013). Review of electrocatalytic properties of Ti-based Ru–Ir oxides in chlorine evolution. International Journal of Electrochemical Science, 8, 11451-11468.

10. Walsh, F. C., & Ponce de León, C. (2018). Progress in electrochemical flow reactors for laboratory and pilot scale processing. Electrochimica Acta, 280, 121-148.

Related Industry Knowledge

- How are Ruthenium Iridium Coated Titanium Anodes Manufactured?

- How Do Ruthenium Iridium Coated Titanium Anodes Work?

- How Sustainable Are Iridium Tantalum Coated Titanium Anodes?

- How do Ruthenium Iridium Coated Titanium Anodes Impact Metal Electrowinning?

- What Industries Commonly Use Ruthenium Iridium Coated Titanium Anodes?

- How Do Iridium Tantalum-Coated Titanium Anodes Function?

- How are Titanium Electrodes Utilized for the Disinfection of Irrigation Water?

- What is Titanium Coated With Ruthenium Iridium?

- Electrochemical Innovation: The Role of Iridium-Tantalum Coated Titanium Anodes

- Revolutionizing Industries: The Power of Ruthenium-Iridium Coated Titanium Anodes