- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Anode Plate

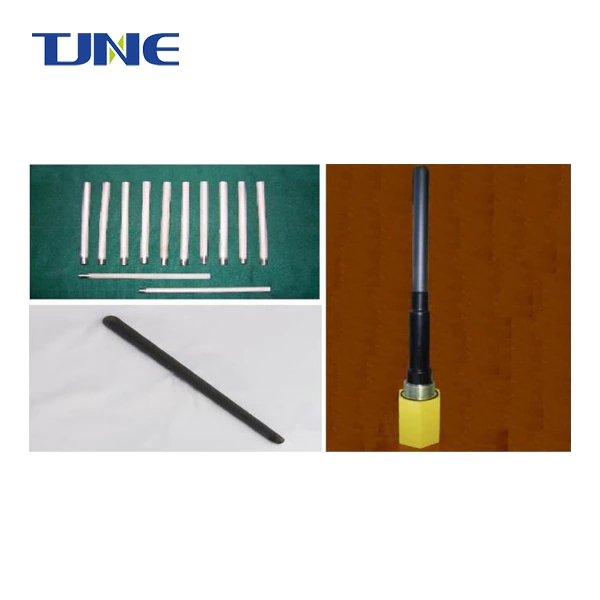

Product Overview: Cathodic protection technology has been widely used in metallurgy, the chemical industry, environmental protection, and anti-corrosion.

Product features: Precious metal oxide composite-coated titanium electrodes can be selected and customized by customers according to their own needs. The length of the anode can be customized according to customer requirements.

Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.

Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.

Commonly used specifications and models of titanium metal conductive sheets are as follows:

Titanium composition:: ASTM B 265GR1

Specifications: Width 12.7mm Thickness 0.90mm

Standard length: 152 meters/roll

What is an Anode Plate

Anode plates manufactured by TJNE are renowned for their high quality and excellent performance in various applications. With strong technical expertise and comprehensive after-sales service, we provide a complete solution for your needs..

Anode Plate is an essential component in electrochemical processes, particularly in electroplating and metal refining applications. It serves as the positive electrode where oxidation occurs, allowing metal ions to be transferred from the anode to the cathode.

Working Principle and Chemical Properties

It is based on the principle of electroplating, where a direct current is applied to the anode, causing the metal to oxidize and dissolve into the electrolyte solution. This leads to the deposition of metal ions onto the cathode, resulting in the desired plating or refining process.

System Components and Detailed Structure

It is composed of a metallic substrate, usually made of titanium or other suitable materials, coated with a layer of electrochemically active material, such as platinum, iridium, or other noble metals. The coating provides the necessary catalytic properties for efficient electrode reactions.

Performance Parameters

| Parameter | Value |

|---|---|

| Coating Thickness | 5-10 µm |

| Specific Surface Area | 100-200 cm²/g |

| Current Density | 500-2000 A/m² |

| Operating Temperature | 0-80°C |

Technical Specifications

| Specification | Value |

|---|---|

| Size (Length x Width x Thickness) | Customizable |

| Coating Material | Platinum, Iridium, etc. |

| Substrate Material | Titanium, etc. |

| Connector Type | Bolt, Thread, etc. |

Economic Indicators

| Indicator | Value |

|---|---|

| Longevity | 10+ years |

| Cost Efficiency | High |

| Maintenance Cost | Low |

Key Features and Advantages

● High-quality metallic substrate for durability and longevity

● Premium coating materials for enhanced electrochemical performance

● Customizable sizes and connector types for easy integration

● Wide operating temperature range for versatile applications

● Cost-effective solution with low maintenance requirements

Application

Anode plates serve important functions across a range of industrial, commercial, and research applications related to electrochemistry. In the metal finishing industry, anode plates are used to facilitate uniform electroplating of metals onto parts and components. By acting as the anode, or positive electrode, high-purity metal anode plates composed of nickel, chromium, tin, zinc, and other metals provide a consistent source of cations for deposition onto the negatively charged cathodic workpieces. This allows industries to efficiently electroplate metal coatings for decorative, anti-corrosion, and wear-resistant purposes.

metal refining

In metal refining processes, insoluble anode plates made from lead alloys, silver-gold alloys, and copper-nickel alloys enable the electrorefining of impure metals into high-purity products. During electrorefining, the impure metals are dissolved from the anode into the electrolyte and deposited onto the cathode, while insoluble, withstand the process without deteriorating. This facilitates the commercial refining of copper and other metals.

Industrial wastewater treatment

For industrial wastewater treatment, stable dimensionally stable anode (DSA) plates coated with specialty mixed metal oxide coatings provide longevity in generating oxygen and other oxidants to degrade contaminants and purify effluent flows electrochemically. This is an essential step in many wastewater systems.

Specialized anode plates are also fabricated for use in the non-membrane chlor-alkali process for the electrochemical conversion of brine solutions into chlorine and sodium hydroxide. High-performance anode materials resist the aggressive brine environment and evolve chlorine gas efficiently.

Research and development settings

In research and development settings, anode plates enable the investigation of electrode reactions and electrolytic processes. Suitable anode materials can be prepared and analyzed for factors like electrocatalytic activity, stability, and overpotential characteristics.

In summary, precisely engineered, it serves critical roles in electroplating processes, metal refining, water treatment, chlor-alkali production, and other electrochemical systems across industrial, commercial, and scientific realms. Their composition, dimensions, and other design parameters can be tailored to meet the needs of a given application where maximizing performance, consistency, and longevity are key priorities. As anode materials and coating technology advance, they will continue improving industrial and commercial electrochemical processes.

FAQ

1. What is the typical lifespan?

It can last for more than 10 years, depending on the specific operating conditions and maintenance practices.

2. Can it be customized for specific requirements?

Yes, we offer customization options for size, coating material, and connector type to meet your specific needs.

If you are in search of a high-quality product, do not hesitate to contact TJNE. We are the experts in Anode Plate manufacturing and supply, providing professional technical support and comprehensive services. Email us at yangbo@tjanode.com for further inquiries.