- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

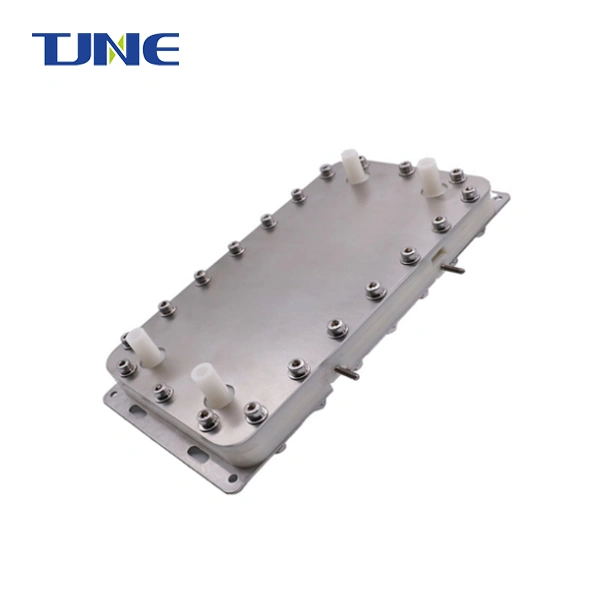

Platinized Titanium Plate

1.Substrate material: TA1, TA2

2.Coating: Platinum coating and can be customized to 0.5-10 µm coating thickness

3.Plate size and thickness: various options available (customizable)

4.pH level: 1-12

Platinized Titanium Plates are highly versatile and can be fabricated in a variety of thicknesses and sizes to meet specific industrial and research needs. TJNE ensures the availability of these plates in standard forms and offer customization options for unique applications. we adhere to stringent quality control measures, such as ASTM testing standards, to deliver high-purity materials with reliable performance. Please contact yangbo@tjanode.com for more information on specifications, delivery time and pricing. Platinized Titanium Plates are essential components in various electrochemical applications, such as electroplating and water electrolysis. These plates are prized for their remarkable combination of durability, conductivity, and corrosion resistance. By merging the robust mechanical properties of titanium with the superior conductivity and electrochemical stability of platinum, these plates have become indispensable for industries requiring reliable and efficient electrochemical performance.

- Durability: Titanium's high resistance to corrosion and platinum's exceptional conductivity ensure long-term use even in challenging environments.

- Eco-Friendly: Reduced chemical additives and low operational costs make this product an environmentally friendly solution.

- Adaptability: The plate performs well across a wide pH range, allowing versatile applications in varied industrial environments.

Platinized Titanium Plates represent a cutting-edge solution for industries relying on electrochemical processes. Their unmatched combination of strength, conductivity, and corrosion resistance positions them as a superior alternative to traditional anode materials. Whether in electroplating, water electrolysis, or other electrochemical applications, these plates provide the durability and efficiency required for long-term success. With options for customization and adherence to industry standards, platinized titanium plates continue to drive innovation and efficiency in electrochemical technologies.

Applications

Platinized Titanium Plates find extensive use in industries that require advanced electrochemical technologies. Some common applications include:

Electroplating

Platinized Titanium Plates play a critical role in electroplating, ensuring precise and efficient deposition of metals onto various surfaces. The platinum coating on these titanium-based anodes significantly enhances their electrocatalytic activity, making them indispensable in achieving high-quality and uniform metal layers. This capability is particularly valuable in industries such as manufacturing and electronics, where durable and aesthetically superior finishes are essential.

Water electrolysis for alkaline and acidic water

These plates enhance the efficiency of water ionization by providing optimal oxidation-reduction potential (ORP) alteration, ensuring superior hydrogen and oxygen production. Alkaline water is often consumed for its potential to neutralize acidity in the body, promote hydration, and provide antioxidant effects due to the presence of dissolved hydrogen. On the other hand, the acidic water produced has applications in sanitation and sterilization, as it can effectively eliminate bacteria and other harmful microorganisms.

HHO generator

Platinized Titanium Plates are essential components in hydrogen generation, particularly in HHO (Hydrogen-Hydrogen-Oxygen) generators. Their enhanced catalytic properties make them indispensable for the electrolysis process, where water molecules are efficiently split into hydrogen and oxygen gases. The high electrochemical efficiency of these plates ensures consistent and effective hydrogen production, which is critical for various applications, including fuel cell technology and clean energy systems.

FAQ

Q: What is the typical lifespan of a Platinized Titanium Plate?

A: Our plates offer a long lifespan and the life of platinized titanium plate depends on the type, working current density, and electrolyte components.

Q: Is the plate suitable for high-temperature operations?

A: For processes requiring higher temperatures, please consult with our technical team.

Q: How does the plate's efficiency compare with other materials?

A: Thanks to platinum's high conductivity and titanium's durability, our products provide nearly 99% efficiency, outpacing conventional electrodes in some electrochemical process.

Contact us

For more information or to discuss your specific application needs, contact us at yangbo@tjanode.com. Our team is ready to provide personalized support and help you determine the best solution for you.

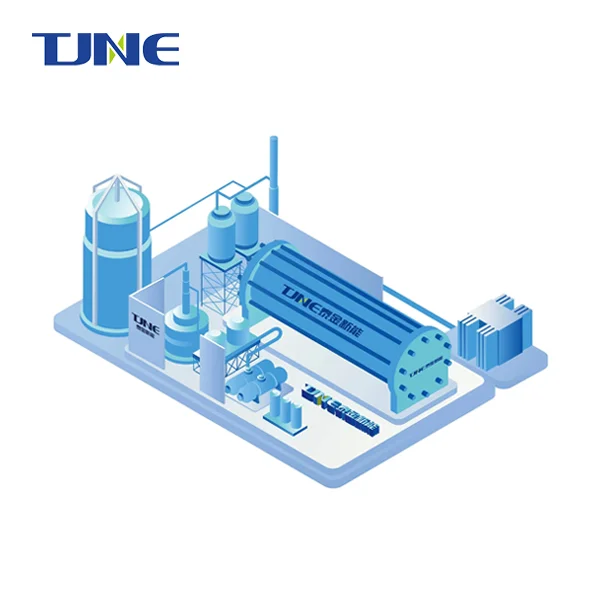

Electrolyzers.webp)