- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

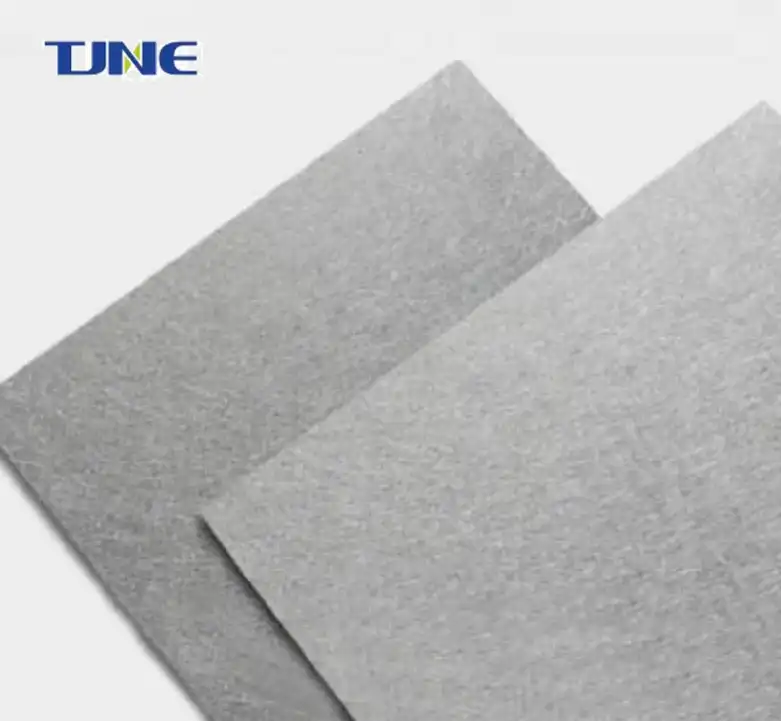

Platinium Coated Titanium Felt

1.Material: TA1, TA2

2.Porosity: 60%-75%

3.Size: 1500*1200mm (customizable)

4.Thickness: 0.25-1mm (customizable)

Platinum coated titanium felt produced by TJNE is a highly specialized material widely used in Proton Exchange Membrane (PEM) electrolyzers. It serves as both a flow field and diffusion medium, playing a critical role in gas and liquid transport while ensuring strong electrical contact between the catalyst layer and the bipolar plate. This optimized interaction enhances the efficiency and durability of the electrolysis process. The material is composed of a thin layer of platinum deposited onto titanium felt, which has been carefully processed to create a smooth, flat surface ideal for electrolysis applications. The platinum coating enhances its electrical conductivity, facilitating efficient charge transfer during hydrogen production. The underlying titanium structure provides mechanical strength and resilience, ensuring long-term stability under demanding operating conditions. One of the key advantages of platinum coated titanium felt is its exceptional corrosion resistance. Unlike traditional carbon-based gas diffusion layers (GDLs), which degrade rapidly under electrolysis conditions—especially in acidic or high-voltage environments—this material remains stable, ensuring long-lasting performance.

- High Corrosion Resistance: The titanium felt coated platinum provides exceptional resistance to oxidation corrosion and hydrogen embrittlement, ensuring longevity in challenging environments.

- Superior Conductivity: The combination of platinum and titanium offers high conductivity and uniform current distribution, critical for effective electrochemical processes.

- Durability and Stability: Engineered for industrial environments, this material is robust and withstands pressure even under prolonged use.

With its high durability, cost-effectiveness, and efficiency, platinum coated titanium felt is a key material for improving the performance and longevity of electrolysis and other electrochemical systems.

Working principle

Platinum coated titanium felt is the key material of gas diffusion layer (GDL) of a Proton Exchange Membrane (PEM) electrolyzer. The working principle of a PEM Electrolyzer revolves around the electrochemical reactions occurring at the membrane electrode assembly (MEA). The MEA consists of a gas diffusion layer, a catalytic layer, and a proton exchange membrane, which together facilitate the conversion of water into hydrogen and oxygen using electrical energy.

In a PEM electrolyzer, water is evenly distributed across the MEA through the gas diffusion layer, which also facilitates efficient gas removal and current conduction.

Oxygen evolution reaction at the anode, water molecules undergo oxidation, producing oxygen gas, protons (H+) and electrons (e-):

H2O→2H++1/2O2+2e-

The generated protons (H+) move through the proton exchange membrane, which allows only protons to pass while blocking electrons and gases.

The electrons (e−) travel through an external circuit from the anode to the cathode, generating an electric current.

Hydrogen evolution reaction at the cathode, the transported protons recombine with electrons to form hydrogen gas:

2H++2e−→H2

The GDL plays a crucial role in optimizing performance by ensuring uniform water distribution, efficient gas removal, and effective electrical conductivity, all of which enhance the efficiency of hydrogen production in the PEM electrolyzer.

Application

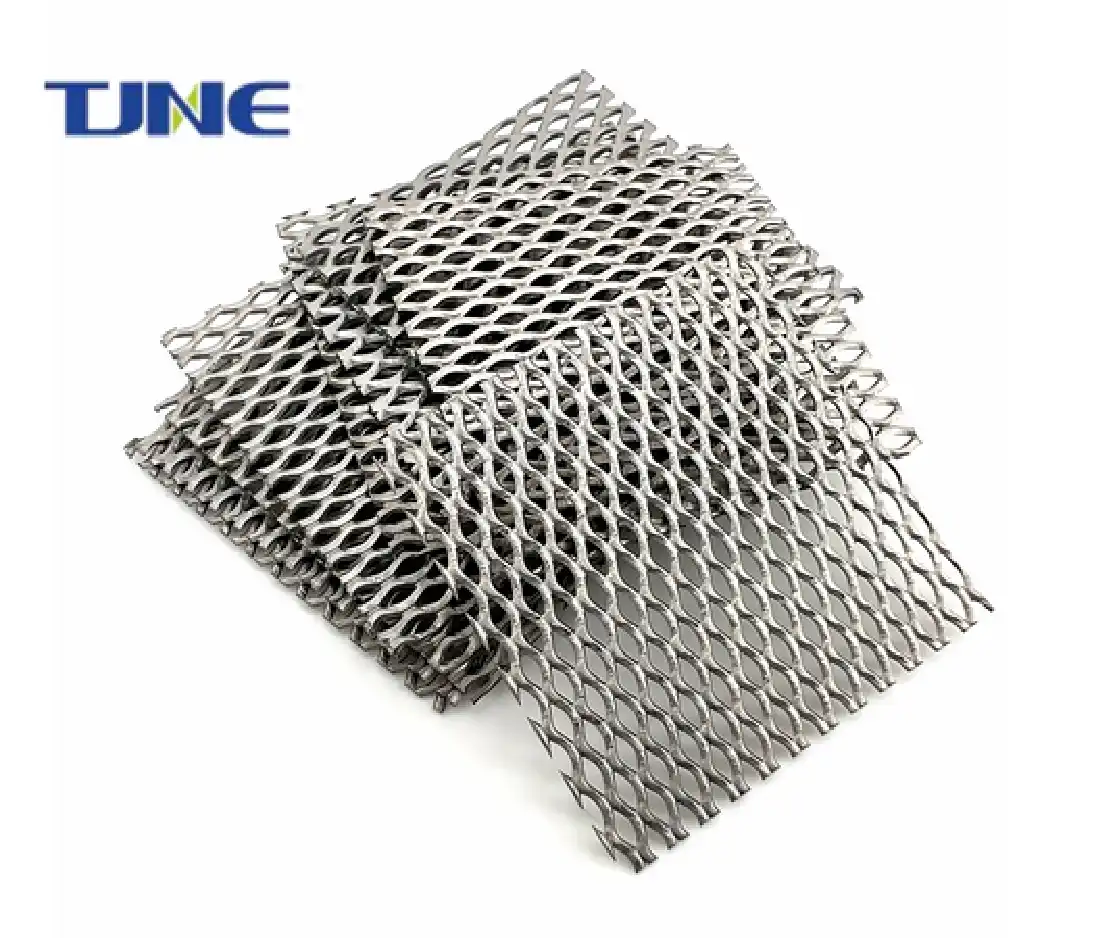

Gas diffusion layer for PEM electrolyzer

With its large active surface area and lightweight, platinum coated titanium felts are primarily used in electrolyzer stacks as the flow field or diffuser material, improving electrochemical reactions.

FAQ

Q1: How long does the platinum coating last?

A: The platinum coating is engineered for durability and can last several years with proper use, depending on the operational environment and intensity.

Q2: Can the thickness of the titanium felt be customized?

A: Yes, the felt thickness can be customized to meet specific requirements for various applications.

Q3: How does it compare in cost to other materials?

A: While initially more costly due to the platinum, it offers greater durability and efficiency, leading to long-term savings on replacement and maintenance.

Contact us

Please contact us at yangbo@tjanode.com for more details about Platinium Coated Titanium Felt, customization possibilities, or to talk about your water treatment requirements. Our staff is committed to assisting you in identifying the best solutions for your electro-oxidation applications and is available to offer comprehensive technical support.

Electrolyzers.webp)