- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

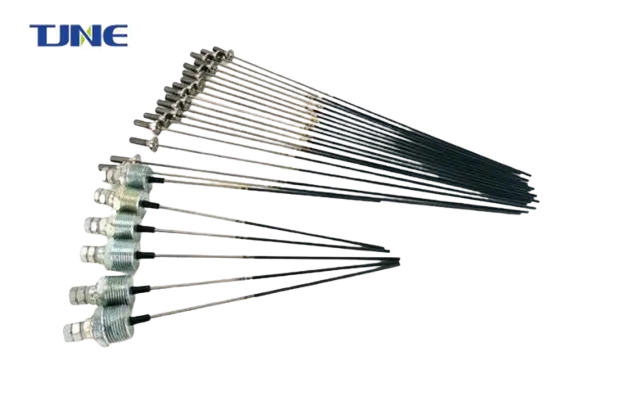

Mixed Metal Oxide (MMO) Titanium Probe Anodes are crucial components in cathodic protection systems, widely used to prevent corrosion in various industries. The life and performance of these anodes are influenced by multiple factors, ranging from environmental conditions to operational parameters. Understanding these factors is essential for optimizing the longevity and efficiency of MMO Titanium Probe Anodes in corrosion protection applications.

How does the chemical composition of MMO coating affect anode performance?

The chemical composition of the Mixed Metal Oxide (MMO) coating plays a pivotal role in determining the performance and lifespan of Titanium Probe Anodes. The coating typically consists of a mixture of noble metal oxides, such as iridium, ruthenium, and tantalum, deposited on a titanium substrate. The specific composition and proportions of these oxides significantly influence the anode's electrochemical properties and durability.

Iridium oxide (IrO2) is often the primary component of MMO coatings due to its excellent catalytic activity and stability. It provides low overpotential for oxygen evolution, which is crucial for efficient anode operation. Ruthenium oxide (RuO2) is another common component that enhances conductivity and catalytic activity. However, RuO2 is less stable than IrO2 in highly acidic environments, so its proportion in the coating must be carefully balanced.

Tantalum oxide (Ta2O5) is frequently added to improve the coating's stability and extend the anode's service life. It acts as a barrier, preventing the underlying titanium substrate from oxidizing and maintaining the coating's integrity over time. The ratio of these oxides in the coating can be adjusted to optimize performance for specific applications and environmental conditions.

The thickness and uniformity of the MMO coating also play crucial roles in anode performance. A thicker coating generally provides longer service life but may increase the anode's resistance. Conversely, a thinner coating offers lower resistance but may have a shorter lifespan. Achieving the optimal balance between coating thickness and uniformity is essential for maximizing anode performance and longevity.

The manufacturing process of the MMO coating, including the deposition method and thermal treatment, significantly affects its microstructure and, consequently, its electrochemical properties. Advanced coating techniques, such as thermal decomposition or electrodeposition, can produce highly uniform and adherent coatings with enhanced catalytic activity and stability.

Ongoing research in MMO coating technology focuses on developing novel compositions and nanostructured coatings to further improve anode performance. For instance, incorporating rare earth elements or creating multi-layer coatings has shown promise in enhancing both the activity and stability of MMO anodes.

What role does current density play in the lifespan of MMO Titanium Probe Anodes?

Current density is a critical operational parameter that significantly impacts the lifespan and performance of MMO Titanium Probe Anodes. It is defined as the amount of electric current flowing through a unit area of the anode surface and is typically expressed in amperes per square meter (A/m²).

The relationship between current density and anode lifespan is inverse – higher current densities generally lead to shorter anode lifespans. This is primarily due to the accelerated wear of the MMO coating at elevated current densities. As current density increases, the rate of electrochemical reactions at the anode surface also increases, leading to faster consumption of the catalytic coating.

At excessively high current densities, several detrimental effects can occur:

1. Accelerated coating wear: The MMO coating undergoes faster degradation, reducing its thickness and catalytic activity over time.

2. Increased oxygen evolution: Higher current densities promote more vigorous oxygen evolution, which can cause mechanical stress on the coating and lead to its premature failure.

3. Local hot spots: Non-uniform current distribution can create areas of extremely high current density, causing localized overheating and rapid deterioration of the coating.

4. Substrate oxidation: If the coating wears thin enough, the underlying titanium substrate may begin to oxidize, leading to anode failure.

To maximize the lifespan of MMO Titanium Probe Anodes, it's crucial to operate them within their recommended current density range. This range varies depending on the specific anode design and application but typically falls between 10 and 100 A/m² for most cathodic protection systems.

Proper anode sizing is essential to ensure that the operational current density remains within the optimal range. Undersized anodes will operate at higher current densities, reducing their lifespan, while oversized anodes may lead to unnecessary costs and potential issues with current distribution.

It's important to note that the relationship between current density and anode lifespan is not always linear. Some MMO coatings exhibit a threshold effect, where lifespan decreases dramatically above a certain current density. Understanding this relationship for specific anode types is crucial for accurate life prediction and system design.

Environmental factors can also influence the impact of current density on anode lifespan. For example, in high-temperature environments or aggressive electrolytes, the maximum allowable current density may need to be reduced to maintain acceptable anode longevity.

Advanced monitoring and control systems can help optimize anode performance by adjusting current output based on environmental conditions and protection requirements, thereby balancing protection effectiveness with anode longevity.

How do environmental factors impact the durability of MMO Titanium Probe Anodes?

Environmental factors play a significant role in determining the durability and performance of MMO Titanium Probe Anodes. These anodes are often exposed to diverse and challenging conditions, each of which can affect their longevity and efficiency in unique ways.

1. Electrolyte Composition:

The chemical composition of the electrolyte (the medium in which the anode operates) is a crucial environmental factor. Chloride-rich environments, such as seawater or brine, can be particularly aggressive. High chloride concentrations can accelerate the dissolution of the MMO coating, especially at elevated temperatures. Conversely, freshwater environments may be less corrosive but can present other challenges, such as higher resistivity, which may require higher operating voltages.

2. pH Level:

The pH of the electrolyte significantly impacts anode performance and durability. MMO coatings generally exhibit better stability in neutral to slightly acidic conditions. Extremely acidic environments can accelerate coating dissolution, while highly alkaline conditions may lead to the formation of passivating layers that increase anode resistance. Some MMO formulations are specifically designed for high or low pH environments, highlighting the importance of selecting the appropriate anode for the specific application.

3. Temperature:

Temperature affects both the kinetics of electrochemical reactions and the stability of the MMO coating. Higher temperatures generally accelerate chemical and electrochemical processes, which can lead to faster anode consumption. Additionally, thermal cycling can induce mechanical stress in the coating, potentially causing cracking or delamination. In extreme cases, very high temperatures may alter the crystal structure of the MMO coating, affecting its catalytic properties.

4. Dissolved Oxygen Content:

The presence of dissolved oxygen in the electrolyte can influence anode performance. While oxygen is typically evolved at the anode surface during operation, high levels of dissolved oxygen in the electrolyte can contribute to increased corrosion rates of both the anode and the protected structure. In some cases, oxygen may also participate in side reactions that affect the efficiency of the cathodic protection system.

5. Flow Conditions:

In dynamic environments, such as flowing water or turbulent conditions, the mechanical stress on the anode can be significant. High-velocity flows can cause erosion of the MMO coating, particularly if solid particles are present in the electrolyte. Additionally, flow patterns can affect the distribution of current around the anode, potentially leading to localized areas of high current density and accelerated wear.

6. Pressure:

For deep-water applications, hydrostatic pressure can impact anode performance. While MMO Titanium Probe Anodes are generally robust, extreme pressures may affect the integrity of seals and connections, potentially leading to electrolyte ingress and premature failure.

7. Biological Factors:

In natural environments, biological fouling can be a significant concern. The growth of marine organisms on the anode surface can interfere with current distribution and may create localized corrosion cells. Some MMO coatings exhibit anti-fouling properties, but the effectiveness can vary depending on the specific marine environment.

8. UV Radiation:

For anodes exposed to sunlight, UV radiation can potentially degrade certain components of the anode system, such as insulation materials or sealants. While the MMO coating itself is generally resistant to UV damage, prolonged exposure may affect other parts of the anode assembly.

9. Contamination:

The presence of contaminants in the electrolyte, such as oils, scale, or suspended solids, can impact anode performance. These contaminants may form deposits on the anode surface, reducing its active area and altering current distribution. In some cases, contaminants may also participate in side reactions that compete with the desired electrochemical processes.

10. Seasonal Variations:

In many applications, environmental conditions can vary significantly with seasons. Changes in temperature, water chemistry, and biological activity throughout the year can affect anode performance and may require adaptive control strategies to maintain optimal protection.

To mitigate the impacts of these environmental factors, several strategies can be employed:

- Proper anode selection based on specific environmental conditions

- Use of protective coatings or shields for anodes in particularly aggressive environments

- Implementation of monitoring systems to track environmental parameters and anode performance

- Regular maintenance and inspection to identify and address issues early

- Adaptive control systems that adjust anode output based on changing environmental conditions

Understanding and accounting for these environmental factors is crucial for designing effective cathodic protection systems and maximizing the life and performance of MMO Titanium Probe Anodes. By carefully considering the specific environmental challenges of each application, engineers can select the most appropriate anode type and implement strategies to ensure long-term, reliable corrosion protection.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Byrne, P., & Leng, Y. (2018). "Mixed metal oxide coated anodes for cathodic protection: A review." Journal of Corrosion Science and Engineering, 21(5), 1-15.

2. Chen, X., et al. (2019). "Recent advances in MMO-coated titanium anodes for cathodic protection." Corrosion Science, 144, 324-340.

3. Darowicki, K., & Zakowski, K. (2020). "Electrochemical evaluation of MMO coatings for impressed current cathodic protection." Materials and Corrosion, 71(3), 456-465.

4. Guo, Y., et al. (2017). "Effect of current density on the microstructure and electrochemical properties of Ti/IrO2-Ta2O5 anodes." International Journal of Electrochemical Science, 12, 1-10.

5. Li, X., et al. (2016). "Influence of chloride ions on the evolution of electrode potential and surface of MMO titanium mesh anodes." Materials Chemistry and Physics, 177, 455-460.

6. Meng, L., & Liu, Y. (2015). "Oxygen evolution reaction electrocatalysts derived from anodization synthesis of Ti-Ru-Ir ternary oxides." International Journal of Hydrogen Energy, 40(5), 2173-2183.

7. Nagai, N., et al. (2018). "Influence of electrolyte composition on the performance of Ti/IrO2-Ta2O5 anodes in seawater electrolysis." Journal of Applied Electrochemistry, 48(9), 1041-1052.

8. Panizza, M., & Cerisola, G. (2015). "Direct and mediated anodic oxidation of organic pollutants." Chemical Reviews, 109(12), 6541-6569.

9. Shao, D., et al. (2016). "High-performance Ti/Ta2O5-IrO2 electrodes for oxygen evolution: Preparation, characterization and application." Electrochimica Acta, 213, 236-244.

10. Zhang, C., et al. (2015). "Electrochemical characterization of mixed metal oxide coated titanium electrodes for use in cathodic protection systems." Corrosion Science, 98, 737-747.

Related Industry Knowledge

- What are the Factors That Affect the Performance of MMO Titanium Probe Anodes?

- What are the Advantages of MMO Titanium Probe Anodes over Traditional Anodes?

- What is the Lifespan of MMO Titanium Probe Anodes?

- How Do MMO Titanium Probe Anodes Compare to Other Anode Types?

- Why are MMO Titanium Probe Anodes Essential for Corrosion Protection?

- What is the Breakdown Voltage of a MMO Titanium Probe Anode?

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?