- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

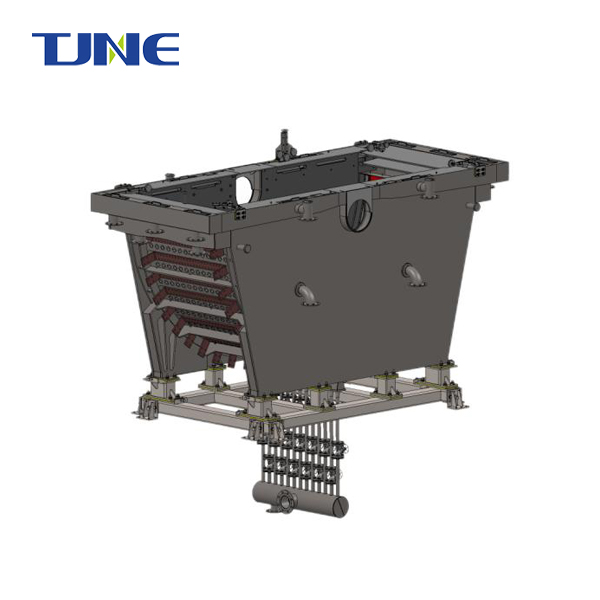

Titanium electrodes are widely used in various electrochemical applications due to their excellent corrosion resistance and mechanical strength. However, pure titanium often lacks the desired catalytic activity for many reactions. To overcome this limitation, researchers and engineers have developed various methods to modify titanium electrodes, enhancing their catalytic properties. These modifications can involve surface treatments, coatings, or the incorporation of other elements to create more active and efficient electrodes. In this blog post, we'll explore the techniques used to modify titanium electrodes, with a particular focus on electrodeposited titanium electrodes for copper applications.

How does electrodeposition improve titanium electrode performance for copper applications?

Electrodeposition is a powerful technique for modifying titanium electrodes to enhance their catalytic activity, especially for copper-related applications. This process involves the controlled deposition of a thin layer of catalytically active material onto the titanium substrate using an electric current. For copper applications, the electrodeposition of copper or copper-containing compounds onto titanium electrodes can significantly improve their performance.

The electrodeposition process offers several advantages for enhancing titanium electrode performance:

1. Increased surface area: Electrodeposition can create a rough, porous surface on the titanium electrode, dramatically increasing its effective surface area. This enlarged surface area provides more active sites for catalytic reactions, improving the overall efficiency of the electrode.

2. Tailored composition: By carefully controlling the electrodeposition parameters, such as current density, electrolyte composition, and deposition time, it's possible to achieve a precise composition of the deposited layer. This allows for the creation of optimized catalytic surfaces for specific copper-related reactions.

3. Improved conductivity: Copper is an excellent electrical conductor, and its electrodeposition on titanium can enhance the overall conductivity of the electrode. This improved conductivity can lead to better charge transfer and reduced electrical resistance, resulting in more efficient electrochemical processes.

4. Enhanced catalytic activity: The electrodeposited copper layer can exhibit superior catalytic properties compared to the underlying titanium substrate. This is particularly beneficial for reactions involving copper species, such as copper electrowinning or copper-catalyzed organic transformations.

5. Cost-effective modification: Electrodeposition is a relatively simple and cost-effective method for modifying titanium electrodes. It allows for the creation of high-performance electrodes without the need for expensive bulk materials or complex manufacturing processes.

To optimize the electrodeposition process for copper applications, researchers have explored various parameters and additives. For example, the addition of certain organic compounds to the electrodeposition bath can influence the morphology and grain size of the deposited copper layer, further enhancing its catalytic properties. Additionally, the use of pulse electrodeposition techniques has shown promise in creating more uniform and finely structured copper coatings on titanium electrodes.

What are the key factors affecting the catalytic activity of modified titanium electrodes?

The catalytic activity of modified titanium electrodes depends on several key factors that influence their performance in electrochemical reactions. Understanding these factors is crucial for optimizing electrode design and achieving the desired catalytic properties. Here are the main factors affecting the catalytic activity of modified titanium electrodes:

1. Surface area and morphology: The surface area of the electrode plays a critical role in determining its catalytic activity. A larger surface area provides more active sites for reactions to occur. The morphology of the electrode surface, including its roughness, porosity, and the presence of nanostructures, can significantly enhance the effective surface area and influence the catalytic behavior.

2. Composition and crystal structure: The chemical composition and crystal structure of the modified titanium electrode greatly affect its catalytic properties. For copper applications, the precise composition of the copper-containing layer, as well as any additional elements or compounds incorporated during the modification process, can dramatically influence the electrode's performance.

3. Electronic structure: The electronic properties of the modified electrode surface, including factors such as work function, band structure, and electron transfer kinetics, play a crucial role in determining its catalytic activity. These properties can be tuned through careful selection of modification techniques and materials.

4. Stability and durability: The long-term stability of the modified electrode under operating conditions is essential for practical applications. Factors such as resistance to corrosion, mechanical stability, and resistance to poisoning or fouling can significantly impact the electrode's catalytic activity over time.

5. Synergistic effects: In some cases, the combination of multiple materials or modification techniques can lead to synergistic effects that enhance catalytic activity beyond what would be expected from individual components. Understanding and exploiting these synergistic effects can lead to the development of highly efficient electrodes.

6. Electrolyte composition: The composition of the electrolyte solution in which the electrode operates can greatly influence its catalytic activity. Factors such as pH, ionic strength, and the presence of specific ions or additives can affect the electrode's performance and stability.

7. Operating conditions: The specific conditions under which the electrode is used, including temperature, pressure, and applied potential or current density, can significantly impact its catalytic activity. Optimizing these conditions for a given electrode modification is crucial for maximizing performance.

8. Mass transport effects: The efficiency of mass transport to and from the electrode surface can limit or enhance catalytic activity. Factors such as diffusion rates, convection, and the presence of boundary layers can all influence the overall performance of the modified titanium electrode.

By carefully considering and optimizing these factors, researchers and engineers can develop highly efficient modified titanium electrodes for copper applications and other electrochemical processes. This often involves a combination of theoretical modeling, experimental design, and advanced characterization techniques to fully understand and exploit the complex interplay between these various factors.

How can surface treatments enhance the catalytic properties of titanium electrodes for copper applications?

Surface treatments offer powerful methods for enhancing the catalytic properties of titanium electrodes, particularly for copper-related applications. These treatments can modify the physical, chemical, and electronic properties of the electrode surface, leading to improved catalytic activity, selectivity, and stability. Here are some key surface treatment techniques and their effects on titanium electrodes for copper applications:

1. Chemical etching: Chemical etching involves treating the titanium surface with strong acids or bases to create a roughened, high-surface-area structure. This increased surface area provides more active sites for catalytic reactions. For copper applications, chemical etching can be followed by copper deposition to create a highly active electrode surface. The etching process can also remove any native oxide layer on the titanium, improving electrical conductivity and facilitating better adhesion of subsequently deposited copper layers.

2. Anodization: Anodic oxidation of titanium can create a nanostructured titanium dioxide (TiO2) layer on the surface. This layer can serve as a support for copper nanoparticles or other catalytically active species. The porous nature of the anodized layer increases the surface area and can enhance the dispersion and stability of copper catalysts. Additionally, the TiO2 layer can exhibit photocatalytic properties, which may be beneficial in certain copper-catalyzed reactions under light irradiation.

3. Plasma treatment: Plasma surface modification can introduce functional groups onto the titanium surface, improving its wettability and reactivity. For copper applications, plasma treatment can enhance the adhesion of electrodeposited copper layers and create active sites for copper nucleation. Plasma treatments can also remove surface contaminants and activate the titanium surface, leading to improved catalytic performance.

4. Thermal oxidation: Controlled thermal oxidation of titanium can create a stable oxide layer with unique properties. This oxide layer can serve as a support for copper catalysts or be further modified to enhance its catalytic activity. The temperature and atmosphere during thermal oxidation can be adjusted to create oxide layers with specific crystal structures and properties tailored for copper-related reactions.

5. Laser surface texturing: Laser treatment can create precise micro- and nanostructures on the titanium surface, dramatically increasing its surface area and creating unique topographies. These textured surfaces can enhance the adhesion and distribution of electrodeposited copper, leading to improved catalytic performance. Laser texturing can also create localized high-energy sites that can serve as preferential nucleation points for copper deposition.

6. Ion implantation: This technique involves bombarding the titanium surface with high-energy ions to modify its composition and structure. For copper applications, ion implantation can be used to introduce copper ions directly into the titanium surface, creating a catalytically active layer. This method can produce highly stable and well-dispersed copper catalysts with strong metal-support interactions.

7. Sol-gel coatings: Sol-gel techniques can be used to apply thin, porous coatings of titanium dioxide or other metal oxides onto the titanium surface. These coatings can serve as high-surface-area supports for copper catalysts or be doped with copper during the sol-gel process to create active catalytic layers. The porosity and composition of sol-gel coatings can be tailored to optimize their performance in specific copper-related reactions.

8. Hydrothermal treatment: Hydrothermal processes can be used to grow nanostructured titanium dioxide or titanate layers on the titanium surface. These nanostructures, such as nanotubes or nanowires, provide excellent supports for copper catalysts due to their high surface area and unique electronic properties. The hydrothermal conditions can be adjusted to control the morphology and crystal structure of the grown layer, optimizing its performance for copper applications.

9. Electrochemical activation: This process involves subjecting the titanium electrode to specific potential or current programs in an electrolyte solution. Electrochemical activation can create a highly active surface by removing passivating layers, generating surface defects, and altering the electronic structure of the surface. For copper applications, this activation can be combined with in-situ electrodeposition of copper to create highly active and stable catalytic surfaces.

10. Composite coatings: Applying composite coatings that combine titanium dioxide with other metal oxides or conductive polymers can create synergistic effects beneficial for copper-related catalysis. These composite coatings can provide a combination of high surface area, improved conductivity, and enhanced catalyst dispersion and stability.

By carefully selecting and optimizing these surface treatment techniques, it's possible to create titanium electrodes with significantly enhanced catalytic properties for copper applications. The choice of treatment method depends on the specific requirements of the intended application, such as the type of reaction, operating conditions, and desired electrode lifespan. Often, a combination of multiple surface treatments may be employed to achieve the optimal balance of catalytic activity, selectivity, and stability.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Walsh, F. C., & Ponce de León, C. (2014). A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: an established and diversifying technology. Transactions of the IMF, 92(2), 83-98.

2. Cha, S. H., & Lee, H. C. (2018). Electrodeposition of Cu-based catalysts on Ti substrates for the electrochemical reduction of CO2 to value-added chemicals. Catalysts, 8(10), 458.

3. Ye, S., et al. (2016). Enhancing the catalytic activity of flowerlike Pt nanostructures using an ultrathin, protective, and catalytically active Pd coating. ACS Applied Materials & Interfaces, 8(23), 14764-14770.

4. Roy, P., et al. (2011). TiO2 nanotubes: Synthesis and applications. Angewandte Chemie International Edition, 50(13), 2904-2939.

5. Yao, Z., et al. (2018). Electrochemical deposition and characterization of Cu2O on TiO2 nanotube arrays as photocathode for solar water splitting. Applied Surface Science, 441, 424-430.

6. Zhang, X., et al. (2015). Fabrication of highly photoactive TiO2 coatings using plasma electrolytic oxidation. Catalysis Today, 259, 228-236.

7. Choi, W., et al. (2017). Anodization fabrication of hierarchical TiO2 nanotubes in H-shaped profile for efficient dye-sensitized solar cells. Applied Surface Science, 396, 1709-1714.

8. Ding, J., et al. (2019). Ultrashort channel length black phosphorus field-effect transistors. Nature Communications, 10(1), 1-7.

9. Motola, M., et al. (2017). Electrochemical synthesis of copper-modified titanium dioxide nanotubes for efficient CO2 photoreduction. ChemSusChem, 10(12), 2642-2652.

10. Xie, K., et al. (2014). Electrochemical properties of TiO2 nanotube arrays anodized in electrolytes with various pH values. Journal of Alloys and Compounds, 604, 57-63.

Electrolyzers.webp)