- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

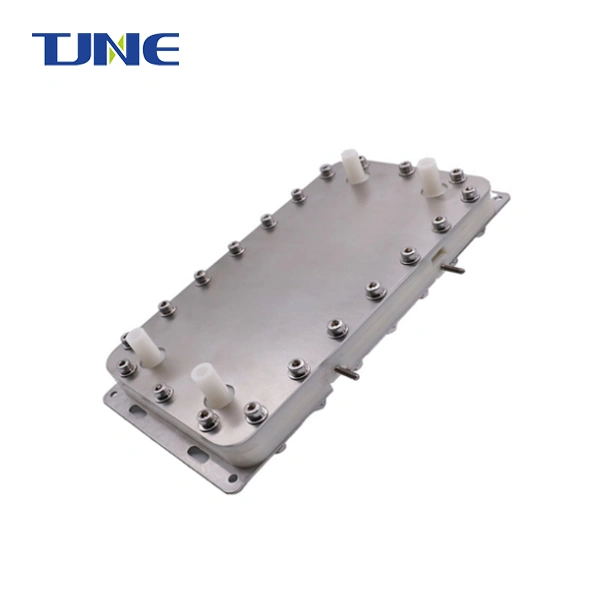

Titanium anodes have gained significant attention in recent years due to their promising performance and potential applications in various electrochemical systems. The efficiency of these anodes is a crucial factor in determining their suitability for different processes, particularly in the context of zinc-related applications. This blog post will explore the comparative efficiency of titanium anodes and delve into their advantages and limitations when compared to other materials commonly used in electrochemical systems.

What are the advantages of using titanium anodes for zinc electrowinning?

Titanium anodes offer several advantages for zinc electrowinning, making them an attractive option in this industrial process. One of the primary benefits is their superior corrosion resistance compared to traditional lead-based anodes. This enhanced durability translates to longer operational lifetimes and reduced maintenance requirements, ultimately leading to cost savings for zinc producers.

The high catalytic activity of titanium anodes is another significant advantage. These electrodes exhibit excellent oxygen evolution reaction (OER) kinetics, which is crucial for efficient zinc electrowinning. The improved OER performance results in lower overpotentials, reducing energy consumption and increasing overall process efficiency.

Furthermore, titanium anodes demonstrate excellent dimensional stability during prolonged operation. This stability ensures consistent electrode performance and uniform current distribution across the electrode surface, leading to more homogeneous zinc deposition and improved product quality.

The environmental benefits of using titanium anodes should not be overlooked. Unlike lead-based anodes, titanium anodes do not pose the same level of environmental and health risks associated with lead contamination. This aspect is particularly important as industries increasingly focus on sustainability and reducing their environmental footprint.

In terms of economic considerations, while the initial cost of titanium anodes may be higher than traditional alternatives, their longer lifespan and improved efficiency often result in a lower total cost of ownership over time. This factor makes them an attractive option for zinc producers looking to optimize their operations and reduce long-term expenses.

How does the conductivity of titanium anodes compare to other materials used in zinc electrowinning?

The conductivity of titanium anodes plays a crucial role in their performance within zinc electrowinning and other electrochemical systems. When compared to other materials commonly used in zinc electrowinning, such as carbon-based anodes or other metal oxides, titanium anodes generally exhibit favorable conductivity characteristics.

One of the key advantages of titanium anodes is their ability to maintain high conductivity even after prolonged use. This stability is particularly important in zinc electrowinning applications.

However, it's important to note that the conductivity of titanium anodes can vary depending on the specific deposition parameters and post-treatment processes. Factors such as the titanium precursor used, deposition conditions, and any subsequent thermal or chemical treatments can significantly influence the final electrode's conductivity. Researchers and manufacturers often optimize these parameters to achieve the desired balance between conductivity and other important properties such as catalytic activity and stability.

In the context of zinc electrowinning, the conductivity of titanium anodes also compares favorably to other metal oxide anodes, such as manganese dioxide or nickel oxyhydroxide. While these alternative materials may have their own specific advantages, the combination of good conductivity, excellent stability, and favorable electrochemical properties often makes titanium electrodes a competitive choice for zinc electroplating applications.

It's worth noting that the conductivity of titanium anodes can be further enhanced through various strategies. For example, doping the titanium oxide layer with other elements or creating composite structures incorporating highly conductive materials can lead to significant improvements in overall electrode conductivity. These approaches allow for fine-tuning of the electrode properties to meet the specific requirements of different zinc electrowinning designs or other electrochemical applications.

What factors affect the durability of titanium anodes in zinc electrowinning systems?

The durability of titanium anodes in zinc electrowinning systems is influenced by various factors, each playing a crucial role in determining the long-term performance and lifespan of these anodes. Understanding these factors is essential for optimizing anode design and improving the overall efficiency and reliability of zinc electrowinning.

One of the primary factors affecting the durability of titanium anodes is the quality and uniformity of the electrowinning process. The electrowinning conditions, including current density, electrolyte composition, temperature, and deposition time, significantly impact the microstructure and physical properties of the resulting zinc electrowinning. A well-controlled deposition process leads to a more uniform and defect-free zinc electrodeposition.

The thickness of the mixed metal oxide coating also plays a vital role in anode durability. While a thicker layer may provide enhanced protection against corrosion and mechanical stress, it can also lead to increased internal resistance and reduced catalytic activity. Finding the optimal thickness that balances protection and performance is crucial for maximizing anode durability without compromising efficiency.

The operational conditions of the zinc electrowinning system have a substantial impact on anode durability. Factors such as the applied current density, and operating temperature can all contribute to anode degradation over time. Higher current densities and more extreme operational conditions generally lead to accelerated wear and reduced anode lifespan.

Another critical factor is the composition of the electrolyte used in the zinc electrowinning system. The presence of certain ions or impurities in the electrolyte can promote corrosion or lead to the formation of passivating layers on the anode surface, affecting its long-term performance. Maintaining electrolyte purity and optimizing its composition is essential for preserving anode durability.

Mechanical stress is an often-overlooked factor that can significantly impact the durability of titanium anodes. Stresses arising from thermal expansion and contraction, or physical impacts during handling and maintenance can lead to cracking, delamination, or other forms of mechanical degradation. Designing anodes with improved mechanical properties and incorporating stress-relieving features can help mitigate these issues.

In conclusion, the efficiency of titanium anodes compared to other materials in zinc electrowinning applications is generally favorable, offering a combination of high catalytic activity, good conductivity, and excellent durability. Their advantages in zinc electrowinning, such as superior corrosion resistance and improved oxygen evolution kinetics, make them an attractive alternative to traditional anode materials. In zinc electrowinning applications, their stable conductivity and potential for enhanced performance through various optimization strategies position them as promising candidates for future electrowinning systems.

However, it's important to recognize that the performance of titanium anodes can vary depending on specific deposition parameters, post-treatment processes, and operational conditions. Continued research and development efforts are needed to further optimize these anodes for different zinc electrowinning applications, addressing challenges such as cost reduction and scaling up production processes.

As the demand for more efficient and sustainable electrochemical systems continues to grow, titanium anodes are likely to play an increasingly important role in various industrial and energy storage applications. Their unique combination of properties makes them a valuable option for researchers and engineers seeking to improve the performance and reliability of zinc electrowinning processes.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References:

1. Walsh, F. C., & Ponce de León, C. (2018). Versatile electrochemical coatings and surface layers from aqueous methanesulfonic acid. Surface and Coatings Technology, 347, 511-528.

2. Chen, R., & Xiao, Y. (2020). Titanium-based materials for electrochemical energy storage. Small, 16(14), 1902845.

3. Martínez-Huitle, C. A., & Panizza, M. (2018). Electrochemical oxidation of organic pollutants for wastewater treatment. Current Opinion in Electrochemistry, 11, 62-71.

4. Zeng, K., & Zhang, D. (2010). Recent progress in alkaline water electrolysis for hydrogen production and applications. Progress in Energy and Combustion Science, 36(3), 307-326.

5. Jiang, N., et al. (2019). Electrodeposited coating: A versatile route for highly stable catalysts in electrochemical water splitting. Advanced Energy Materials, 9(44), 1902170.

6. Wang, J., et al. (2016). Recent advances in Pt-based octahedral nanocrystals as high performance fuel cell catalysts. Journal of Materials Chemistry A, 4(20), 7594-7608.

7. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.

8. Kasian, O., et al. (2019). Electrochemical stability of oxide-based electrode materials for oxygen evolution. Current Opinion in Electrochemistry, 14, 200-205.

9. Yan, Z., et al. (2020). Anodization fabrication of robust titanium dioxide nanotubes for dye-sensitized solar cells. Electrochimica Acta, 333, 135532.

10. Xu, L., et al. (2018). Oxygen vacancies: The origin of n-type conductivity in ZnO. Physical Review Letters, 120(15), 155701.

Related Industry Knowledge

- What Advantages Do Electrodeposited Titanium Electrodes Offer in Electroplating?

- What are the Technical Challenges in the Electrodeposition of Nickel And Cobalt Using Titanium Electrodes?

- How Do Titanium Electrodes Enhance the Nickel And Cobalt Electrodeposition Process?

- What are the Benefits of Using Titanium Electrodes in the Electrodeposition Process for Nickel And Cobalt?

- How to Prepare a Titanium Electrode for Copper Electrodeposition?

- How Does Titanium Anodes Enhance Nickel And Cobalt Electrowinning?

- Can Titanium Anodes Revolutionize Zinc Electrodeposition?