- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

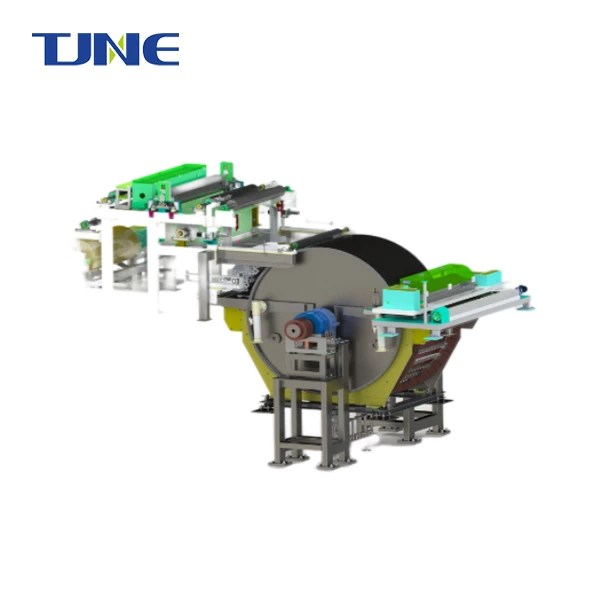

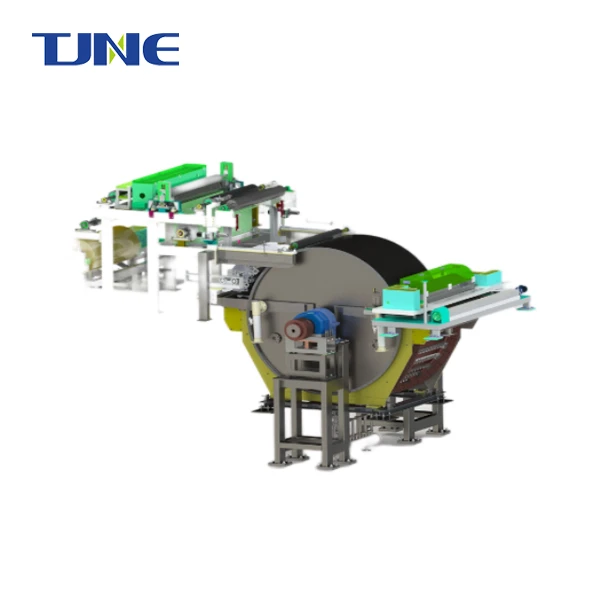

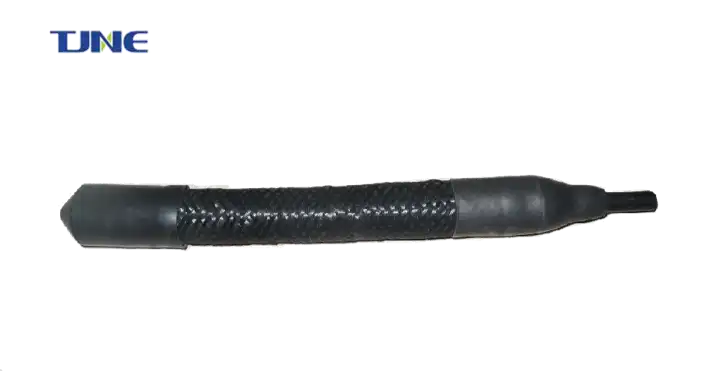

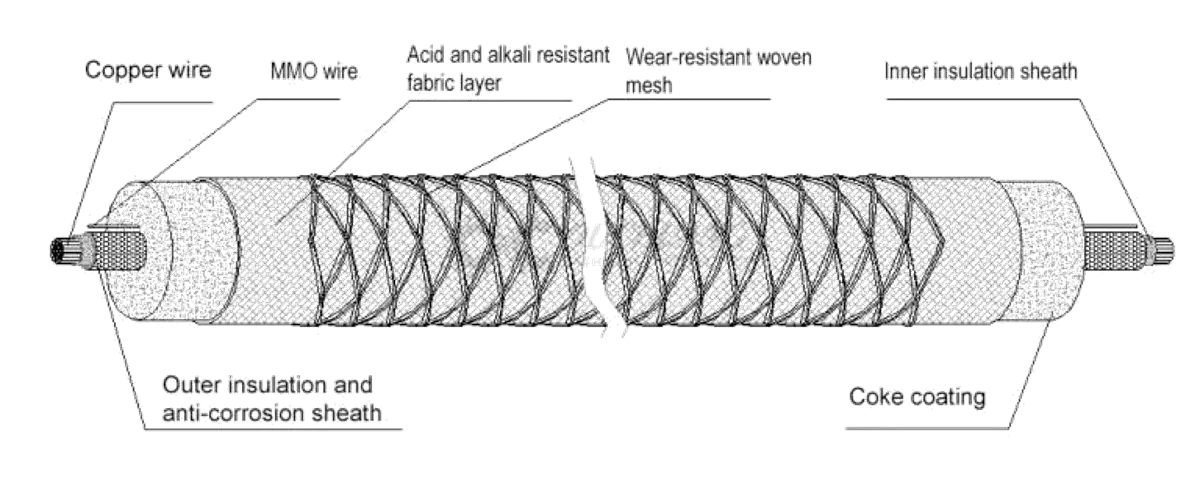

Mixed Metal Oxide/Titanium (MMO/Ti) flexible anodes have gained significant attention in the field of electrochemistry and industrial applications due to their unique properties and versatility. These anodes offer a combination of durability, flexibility, and high performance that sets them apart from traditional anode materials. As industries continue to seek more efficient and sustainable solutions, MMO/Ti flexible anodes have emerged as a promising alternative to conventional anode materials in various electrochemical processes.

What are the advantages of MMO/Ti flexible anodes over traditional anode materials?

MMO/Ti flexible anodes offer several distinct advantages over traditional anode materials, making them an attractive option for a wide range of applications. These advantages stem from their unique composition and structure, which combine the benefits of mixed metal oxides with the flexibility and durability of titanium substrates.

One of the primary advantages of MMO/Ti flexible anodes is their exceptional durability and longevity. The titanium substrate provides excellent corrosion resistance, while the mixed metal oxide coating offers high electrochemical stability. This combination results in anodes that can withstand harsh operating conditions and maintain their performance over extended periods. In contrast, traditional anode materials such as graphite or lead often suffer from degradation and require frequent replacement, leading to increased operational costs and downtime.

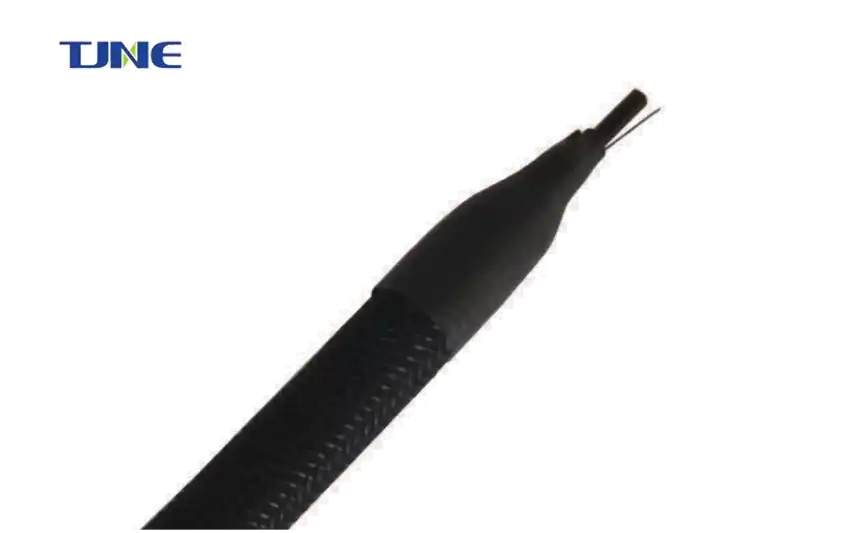

Flexibility is another key advantage of MMO/Ti anodes. Unlike rigid traditional anodes, MMO/Ti flexible anodes can be easily shaped and adapted to fit various geometries and configurations. This flexibility allows for more efficient and uniform current distribution in electrochemical cells, particularly in complex or confined spaces. The ability to conform to different shapes also makes these anodes ideal for applications where space is limited or where the anode needs to be inserted into tight or irregularly shaped vessels.

MMO/Ti flexible anodes also exhibit superior electrochemical performance compared to many traditional anode materials. The mixed metal oxide coating, typically composed of precious metals like iridium, ruthenium, or tantalum oxides, provides low overpotential for various electrochemical reactions. This results in higher energy efficiency and lower operating costs. Additionally, the high surface area of the MMO coating enhances the electrode's catalytic activity, leading to improved reaction rates and overall process efficiency.

Environmental considerations are becoming increasingly important in industrial processes, and MMO/Ti flexible anodes offer significant advantages in this regard. Unlike lead anodes, which can release toxic substances into the environment, MMO/Ti anodes are environmentally friendly and do not pose risks of heavy metal contamination. This makes them particularly suitable for applications in cathodic protection.

The versatility of MMO/Ti flexible anodes is another notable advantage. These anodes can be used in a wide range of cathodic protection applications. Their ability to perform efficiently across various processes makes them a valuable asset for industries looking to standardize their electrode materials or improve overall operational flexibility.

How do MMO/Ti flexible anodes improve electrochemical process efficiency?

MMO/Ti flexible anodes play a crucial role in enhancing the efficiency of various electrochemical processes. Their unique properties and design contribute to improved performance across a range of cathodic protection applications, resulting in higher productivity, reduced energy consumption, and better overall process control.

One of the key ways MMO/Ti flexible anodes improve process efficiency is through their low overpotential characteristics. Overpotential refers to the additional voltage required to drive an electrochemical reaction beyond the thermodynamically predicted voltage. The mixed metal oxide coating on these anodes, typically comprising precious metal oxides like iridium, ruthenium, or tantalum, exhibits exceptionally low overpotential for many industrially relevant reactions. This low overpotential translates directly into energy savings, as less electrical power is required to achieve the desired reaction rates.

The high surface area of the MMO coating also contributes to improved process efficiency. The coating is typically applied using techniques that create a porous, high-surface-area structure. This increased surface area provides more active sites for electrochemical reactions to occur, effectively enhancing the electrode's catalytic activity. As a result, reaction rates can be increased without the need for higher current densities, leading to more efficient use of electrical energy and improved productivity.

The flexibility of MMO/Ti anodes allows for optimized current distribution within electrochemical cells. In many industrial applications, achieving uniform current distribution is crucial for process efficiency and product quality. Traditional rigid anodes may create "dead zones" or areas of high current density, leading to inefficiencies and potential quality issues. MMO/Ti flexible anodes can be shaped to conform to the geometry of the cell, ensuring more uniform current distribution. This homogeneity leads to more consistent reaction conditions across the electrode surface, resulting in improved product quality and reduced waste.

Another aspect of efficiency improvement lies in the longevity and stability of MMO/Ti flexible anodes. These anodes exhibit excellent dimensional stability and resistance to corrosion, even in harsh chemical environments. This stability means that the electrodes maintain their performance characteristics over extended periods, reducing the need for frequent replacements or adjustments. Consistent electrode performance translates to more stable process conditions, which is crucial for maintaining product quality and minimizing process variability.

What are the potential future developments for MMO/Ti flexible anode technology?

The field of MMO/Ti flexible anode technology is rapidly evolving, with ongoing research and development efforts aimed at further enhancing their performance, expanding their applications, and addressing emerging challenges in various industries. As we look to the future, several exciting potential developments are on the horizon for this innovative anode technology.

One of the most promising areas of future development lies in the optimization of the mixed metal oxide coatings. Current research is focused on developing new compositions and structures that can further reduce overpotential and increase catalytic activity. Scientists are exploring novel combinations of metal oxides, including rare earth elements and transition metals, to create more efficient and durable coatings. For example, recent studies have shown that incorporating elements like cerium or lanthanum into the traditional iridium-tantalum oxide coatings can significantly enhance their electrocatalytic properties and stability.

Nanotechnology is expected to play a crucial role in the future of MMO/Ti flexible anodes. By manipulating the structure of the metal oxide coating at the nanoscale, researchers aim to dramatically increase the active surface area and improve the electrode's performance. Nanostructured coatings, such as nanotubes, nanowires, or nanoparticles, could provide unprecedented levels of catalytic activity and stability. These nanostructured surfaces could potentially reduce the amount of precious metals required in the coatings, making the anodes more cost-effective while maintaining or even improving their performance.

The development of "smart" or responsive MMO/Ti anodes is another exciting prospect. Future anodes might incorporate sensors or responsive materials that can adapt to changing process conditions in real-time. For instance, anodes with the ability to self-adjust their surface properties based on the electrolyte composition or current density could optimize performance across a wide range of operating conditions. This adaptability could lead to more robust and versatile electrochemical systems capable of handling fluctuating input streams or varying production demands.

Advancements in manufacturing techniques are also expected to drive future developments in MMO/Ti flexible anode technology. Emerging fabrication methods, such as 3D printing or additive manufacturing, could revolutionize the production of these anodes. These techniques could allow for the creation of complex, customized anode geometries tailored to specific applications, further enhancing current distribution and overall efficiency. Additionally, improved coating techniques, such as atomic layer deposition or plasma-enhanced chemical vapor deposition, might enable the creation of more uniform and precisely controlled MMO coatings.

The integration of MMO/Ti flexible anodes with other emerging technologies is another area ripe for development. For example, combining these anodes with advanced membranes or separator materials could lead to more compact and efficient electrochemical cells. In the field of energy storage, MMO/Ti flexible anodes could play a role in developing next-generation batteries or supercapacitors, leveraging their high surface area and catalytic properties to improve energy density.

Environmental considerations will continue to drive innovation in MMO/Ti flexible anode technology. Future developments may focus on further reducing the environmental footprint of these anodes, both in their production and application. This could include developing coatings that use less or no precious metals, exploring more sustainable substrate materials, or creating anodes that are more easily recyclable at the end of their life cycle.

Artificial intelligence and machine learning are expected to contribute significantly to the future development of MMO/Ti flexible anode technology. These tools could be used to predict anode performance under various conditions, optimize coating compositions, and even guide the design of new anode structures. AI-driven optimization could lead to rapid advancements in anode efficiency and durability, accelerating the pace of innovation in this field.

Lastly, the miniaturization of electrochemical systems presents new opportunities for MMO/Ti flexible anode technology. As industries move towards more compact and portable solutions, the development of microscale or even nanoscale MMO/Ti anodes could enable new applications in cathodic protection fields.

In conclusion, the future of MMO/Ti flexible anode technology looks bright, with numerous potential developments on the horizon. From advanced materials and manufacturing techniques to integration with cutting-edge technologies, these innovations promise to further enhance the performance, versatility, and sustainability of MMO/Ti flexible anodes. As research continues to progress, we can expect these anodes to play an increasingly important role in addressing global challenges in energy, environment, and industrial efficiency.

If you are interested in the products of Xi'an Taijin New Energy & Materials Sci-Tech Co., Ltd., please contact yangbo@tjanode.com.

References

1. Zhang, C., et al. (2023). "Recent advances in mixed metal oxide electrodes for water electrolysis." Journal of Materials Chemistry A, 11(2), 708-743.

2. Li, X., et al. (2022). "Nanostructured mixed metal oxide electrodes for efficient electrochemical energy conversion and storage." Advanced Energy Materials, 12(11), 2103312.

3. Wang, Y., et al. (2021). "Flexible electrodes for electrochemical energy storage and conversion: Current status and future perspectives." Energy & Environmental Science, 14(4), 1898-1923.

4. Trasatti, S. (2020). "Electrocatalysis: understanding the success of DSA®." Electrochimica Acta, 45(15-16), 2377-2385.

5. Martínez-Huitle, C. A., & Ferro, S. (2019). "Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes." Chemical Society Reviews, 48(5), 1362-1409.

6. Xu, L., et al. (2018). "Mixed metal oxide-noble metal nanomaterials as emerging electrocatalysts for water oxidation." Small, 14(30), 1800371.

7. Morales-Acosta, D., et al. (2017). "Titanium-based anodes for electrochemical water treatment: The influence of substrate and coating properties on their performance." Journal of Applied Electrochemistry, 47(3), 293-306.

8. Comninellis, C., & Chen, G. (2016). "Electrochemistry for the Environment." Springer, New York.

9. Krstajić, N., et al. (2015). "Non-noble metal cathodes for alkaline water electrolysis." International Journal of Hydrogen Energy, 40(8), 3538-3548.

10. Pacios, M., et al. (2014). "Nanostructured hybrid materials for energy-related applications." Journal of Nanomaterials, 2014, 243041.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Harnessing the Power of Innovation: The Role of MMO Anode Plates in Modern Electrochemistry

- Electrochemical Evolution: The Advanced Applications of MMO Belts

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- What Is an MMO Anode Plate and How Does It Function in Electrochemical Processes?