- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

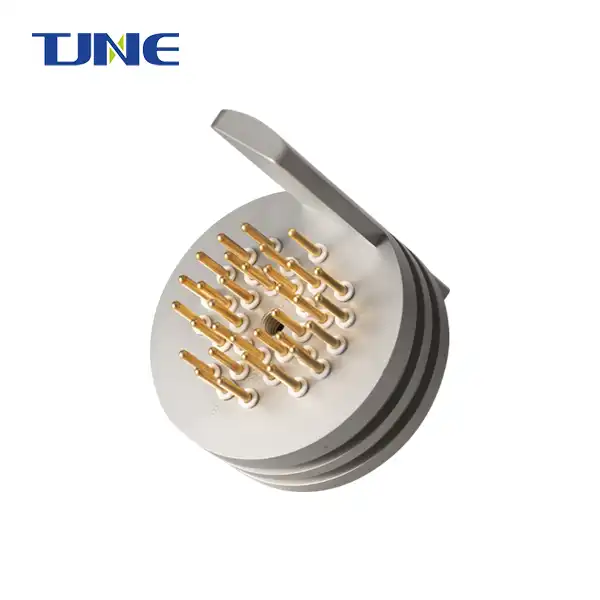

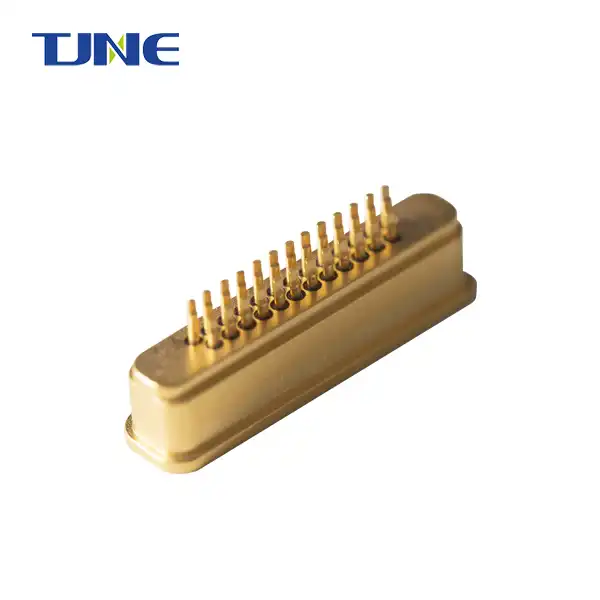

Hermetic Connectors

Product Overview: Hermetic connectors play a vital role in ensuring the integrity of critical electronic systems by providing a reliable seal against environmental elements.

Product advantages: Airtight Sealing, High Hermeticity, Rugged Construction, Customizable Solutions

Technical advantages:

They are engineered to withstand extreme conditions including high-pressure differentials, temperature variations, and exposure to moisture

After-sales service: Providing timely and high-quality worldwide services

Product Details

Hermetic connectors are specifically designed to provide airtight and moisture-proof sealing for electrical and optical connections in environments where exposure to harsh conditions could compromise the integrity of the system. These connectors are crucial for applications in industries such as aerospace, defense, medical, and industrial where maintaining hermeticity is essential.

Performance Parameters

|

Parameter |

Value |

|

Hermeticity Level |

<1x10^-8 atm cc/s He |

|

Operating Temperature |

-65°C to +175°C |

|

Contact Resistance |

<12mΩ |

|

Insulation Resistance |

>5000MΩ at 500VDC |

|

Mating Cycles |

Up to 500 cycles |

Features and Advantages

Hermetic connectors offer a few highlights and preferences that make them vital in different industries:

Airtight and Moisture-proof Fixing: They are outlined to give a dependable seal against natural components, counting dampness, clean, and other contaminants. This fixing capability makes a difference avoid erosion, oxidation, and corruption of touchy electronic components, guaranteeing the long-term unwavering quality of basic systems.

Resistance to Unforgiving Conditions: These connectors are built to withstand extraordinary natural conditions such as tall weight differentials, temperature varieties, stun, and vibration. This strength makes them perfect for utilize in requesting applications where customary connectors would fail.

Long-Term Unwavering quality: They are known for their strength and long-term unwavering quality, indeed in challenging working situations. By keeping up hermeticity over expanded periods, these connectors guarantee the continuous execution of basic electronic and optical systems.

Versatility: They are accessible in different setups to oblige diverse necessities, counting electrical, optical, and cross breed associations. They can be customized to meet particular application needs, making them flexible arrangements for a wide run of businesses and applications.

Hermeticity Testing: These connectors experience thorough testing to guarantee they meet rigid hermeticity measures. This testing confirms the astuteness of the seal and guarantees that the connectors keep up their fixing properties beneath different working conditions.

Compatibility: They are outlined to be congruous with standard connector interfacing, permitting for simple integration into existing frameworks. This compatibility rearranges establishment and upkeep forms, decreasing downtime and generally costs.

Application Areas

Aviation and Flying: Hermetic connectors are broadly utilized in aviation and flying applications, counting air ship, satellites, shuttle, and unmanned airborne vehicles (UAVs). They give solid associations for communication frameworks, flying, route hardware, and other basic hardware working in unforgiving environments.

Defense and Military: It play a significant part in military and defense applications, counting military vehicles, weapons frameworks, radar frameworks, and communication systems. They guarantee secure and solid associations for mission-critical hardware conveyed in challenging operational environments.

Medical Gadgets: They are utilized in restorative gadgets and hardware where unwavering quality and sterility are fundamental. They give fixed associations for gadgets such as implantable therapeutic gadgets, symptomatic gear, surgical apparatuses, and quiet observing frameworks, guaranteeing secure and solid operation.

Industrial Hardware: Hermetic connectors are utilized in different mechanical applications, counting oil and gas investigation, mining, control era, and chemical handling. They give fixed associations for sensors, instrumented, control frameworks, and other electronic components working in cruel mechanical environments.Telecommunications: They are utilized in broadcast communications foundation, counting fiber optic systems, media transmission towers, and information centers. They guarantee dependable optical associations for high-speed information transmission and communication frameworks, indeed in situations with tall stickiness or temperature vacillations.

FAQ

Q:How are them tried for reliability?

A:They experience thorough testing to guarantee they meet rigid hermeticity measures. Testing strategies may incorporate helium spill testing, weight testing, temperature cycling, vibration testing, and mugginess testing.

Q:Can it be customized for particular applications?

A:Yes, It can be customized to meet particular application necessities, counting diverse connector sorts, sizes, stick arrangements, materials, and fixing strategies.

In conclusion

TJNE is a professional manufacturer and supplier of it, offering strong technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, secure packaging, and testing support. If you are seeking high-quality hermetic connectors tailored to your specific requirements, we welcome you to contact yangbo@tjanode.com for personalized solutions.