- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

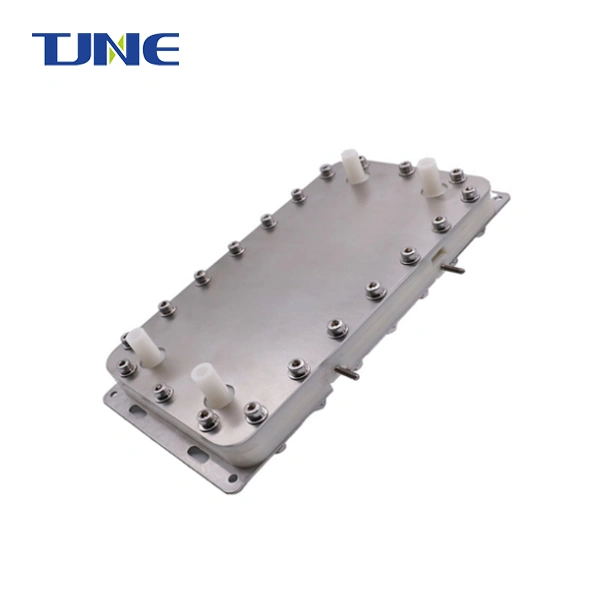

Titanium electrodes play a crucial role in modern ballast water treatment systems, helping to address one of the most pressing environmental challenges in maritime transportation. These electrodes are at the heart of electrochemical disinfection processes that effectively neutralize harmful microorganisms in ballast water, preventing the spread of invasive species across different marine ecosystems. By leveraging the unique properties of titanium, such as its corrosion resistance and electrical conductivity, these electrodes enable efficient and sustainable treatment solutions that comply with stringent international regulations.

What are the advantages of using titanium electrodes in ballast water treatment systems?

Titanium electrodes offer several significant advantages in ballast water treatment systems, making them a preferred choice for many manufacturers and operators. First and foremost, titanium's exceptional corrosion resistance is paramount in the harsh marine environment. Seawater is highly corrosive due to its high salt content and the presence of various minerals. Titanium forms a stable oxide layer on its surface when exposed to oxygen, providing a natural protective barrier against corrosion. This resistance ensures the longevity of the electrodes, reducing maintenance requirements and operational costs over time.

Another key advantage is titanium's excellent electrical conductivity. While not as conductive as copper or silver, titanium strikes an ideal balance between conductivity and corrosion resistance. This property allows for efficient electron transfer during the electrolysis process, which is essential for generating disinfecting agents such as chlorine, ozone, or hydroxyl radicals. The efficiency of this process directly impacts the effectiveness of the ballast water treatment system in neutralizing harmful microorganisms.

Titanium electrodes also boast a high strength-to-weight ratio. This characteristic is particularly valuable in maritime applications where weight considerations are crucial. Lighter components contribute to overall fuel efficiency and vessel performance. Additionally, titanium's durability means that these electrodes can withstand the physical stresses associated with shipboard operations, including vibrations and potential impacts.

The biocompatibility of titanium is another advantage worth noting. Although this property is more commonly associated with medical implants, it has relevance in ballast water treatment as well. The non-toxic nature of titanium ensures that no harmful substances leach into the treated water, maintaining the ecological integrity of the discharged ballast water.

Lastly, titanium electrodes offer excellent dimensional stability. Unlike some other materials that may deform or change shape under electrical current or chemical reactions, titanium maintains its form. This stability is crucial for maintaining consistent performance over time and ensuring uniform treatment of ballast water throughout the system's lifespan.

How do titanium electrodes enhance the efficiency of electrochemical disinfection in ballast water?

Titanium electrodes are instrumental in enhancing the efficiency of electrochemical disinfection processes in ballast water treatment. The primary mechanism by which these electrodes contribute to disinfection is through the generation of powerful oxidizing agents directly from the constituents of seawater. When an electric current is passed through seawater using titanium electrodes, it triggers a series of electrochemical reactions that produce disinfectants in situ.

One of the main products of this electrolysis process is hypochlorite, a potent disinfectant. The chloride ions naturally present in seawater are oxidized at the anode (positively charged electrode) to form chlorine, which then reacts with water to produce hypochlorous acid and hypochlorite ions. These chlorine species are highly effective in destroying or inactivating a wide range of microorganisms, including bacteria, viruses, and larger organisms like plankton.

The efficiency of this process is significantly enhanced by the use of titanium electrodes. The stable oxide layer on the titanium surface acts as a catalyst for these reactions, promoting the formation of oxidizing agents while resisting degradation itself. This catalytic effect increases the yield of disinfectants per unit of electrical energy input, making the overall process more energy-efficient.

Moreover, titanium electrodes can be engineered with specific coatings or dopants to further enhance their catalytic properties. For instance, electrodes coated with mixed metal oxides (MMO) containing ruthenium or iridium oxides can dramatically increase the production of chlorine and other oxidizing species. These advanced electrode designs push the boundaries of efficiency in electrochemical disinfection.

Another aspect of efficiency enhancement lies in the electrode's ability to maintain consistent performance over time. The corrosion resistance of titanium ensures that the electrode surface remains active and uncompromised, even after prolonged exposure to seawater and electrical currents. This consistency is crucial for maintaining the treatment system's efficacy throughout its operational life, ensuring that every batch of ballast water is treated to the same high standard.

The use of titanium electrodes also allows for the implementation of more advanced treatment strategies. For example, some systems employ a combination of direct and indirect oxidation processes. In direct oxidation, microorganisms are destroyed through direct contact with the electrode surface. Indirect oxidation involves the generation of oxidizing agents in the bulk solution, which then diffuse and react with contaminants. Titanium's versatility enables the design of electrode configurations that optimize both these processes, leading to more comprehensive and efficient treatment.

Furthermore, the dimensional stability of titanium electrodes contributes to the overall efficiency of the system. Consistent electrode geometry ensures uniform current distribution and predictable electrochemical reactions. This uniformity is essential for achieving reliable disinfection results and minimizing the risk of undertreated water zones within the ballast tanks.

What are the environmental implications of using titanium electrodes in ballast water management?

The use of titanium electrodes in ballast water management systems has significant environmental implications, most of which are positive. Perhaps the most crucial environmental benefit is the prevention of biological invasions caused by the transfer of non-native species through ballast water. By effectively neutralizing a wide range of organisms, from microscopic bacteria to larger planktonic species, titanium electrode-based systems help maintain the ecological balance of marine ecosystems worldwide.

One of the key environmental advantages of titanium electrodes is their role in reducing the reliance on chemical biocides. Traditional ballast water treatment methods often involved adding chemicals like chlorine or bromine compounds directly to the water. While effective, these approaches risked introducing harmful chemical residues into marine environments upon discharge. Titanium electrode systems, by generating disinfectants in situ through electrolysis, minimize the need for chemical storage and handling on ships. This not only reduces the risk of chemical spills but also ensures that the treated water contains minimal residual chemicals when discharged.

The longevity and durability of titanium electrodes also have positive environmental implications. The extended lifespan of these components means fewer replacements are needed over time, reducing the overall material consumption and waste generation associated with ballast water treatment systems. This aspect aligns well with the principles of sustainable resource use and circular economy practices in the maritime industry.

However, it's important to consider the full lifecycle environmental impact of titanium electrodes. The production of titanium is an energy-intensive process, and the mining of titanium ores can have local environmental impacts. Therefore, the environmental benefits of using titanium electrodes in ballast water treatment must be weighed against the ecological footprint of their production. That said, the long service life and efficiency gains provided by titanium electrodes often outweigh the initial environmental costs of production when considered over the entire lifecycle of the treatment system.

Another environmental consideration is the fate of the oxidizing agents produced by titanium electrodes. While these compounds are highly effective in treating ballast water, their potential impact on marine life upon discharge needs careful management. Most modern systems include neutralization steps to ensure that residual oxidants are broken down to harmless compounds before the treated water is released. The precise control offered by titanium electrode systems allows for optimized production of oxidants, minimizing the need for neutralization and further reducing environmental impact.

The use of titanium electrodes also supports the development of more compact and energy-efficient ballast water treatment systems. This indirectly contributes to environmental protection by reducing the overall energy consumption of ships, thereby lowering greenhouse gas emissions associated with maritime transportation.

In conclusion, titanium electrodes have revolutionized ballast water treatment, offering a robust, efficient, and environmentally friendly solution to one of the most significant challenges in maritime environmental protection. Their unique properties enable the design of treatment systems that effectively neutralize invasive species while minimizing chemical usage and environmental impact. As regulations governing ballast water management continue to evolve, the role of titanium electrodes in ensuring compliance and protecting marine ecosystems is likely to grow even further. Ongoing research and development in this field promise to unlock even more potential for these remarkable components, paving the way for more sustainable and effective ballast water management practices in the future.

If you are interested in the products of Xi'an Taijin New Energy Technology Co., Ltd., please contact yangbo@tjanode.com.

References:

1. International Maritime Organization. (2004). International Convention for the Control and Management of Ships' Ballast Water and Sediments.

2. Tsolaki, E., & Diamadopoulos, E. (2010). Technologies for ballast water treatment: a review. Journal of Chemical Technology & Biotechnology, 85(1), 19-32.

3. Moreno-Andrés, J., Romero-Martínez, L., Acevedo-Merino, A., & Nebot, E. (2017). Effectiveness of a continuous flow-through UVC/H2O2 reactor for inactivation of Escherichia coli in simulated ballast water treatments. Environmental Technology, 38(6), 744-750.

4. Paolucci, E. M., Hernandez, M. R., Potapov, A., Lewis, M. A., & MacIsaac, H. J. (2015). Hybrid system increases efficiency of ballast water treatment. Journal of Applied Ecology, 52(2), 348-357.

5. Nanayakkara, K. G. N., Alam, A. K. M. K., Zheng, Y. M., & Chen, J. P. (2012). A low-energy intensive electrochemical system for the eradication of Escherichia coli from ballast water: process development, disinfection chemistry, and kinetics modeling. Marine Pollution Bulletin, 64(6), 1238-1245.

6. Lacasa, E., Tsolaki, E., Sbokou, Z., Rodrigo, M. A., Mantzavinos, D., & Diamadopoulos, E. (2013). Electrochemical disinfection of simulated ballast water on conductive diamond electrodes. Chemical Engineering Journal, 223, 516-523.

7. Gao, Y., Dong, Y., Guo, J., & Wang, Z. (2015). Evaluation of the performance of a pilot-scale ballast water treatment system based on hydroxyl radicals. Water Science and Technology, 71(9), 1401-1406.

8. Gollasch, S., David, M., Voigt, M., Dragsund, E., Hewitt, C., & Fukuyo, Y. (2007). Critical review of the IMO international convention on the management of ships' ballast water and sediments. Harmful Algae, 6(4), 585-600.

9. Werschkun, B., Sommer, Y., & Banerji, S. (2012). Disinfection by-products in ballast water treatment: An evaluation of regulatory data. Water Research, 46(16), 4884-4901.

10. Batista, W. R., Fernandes, F. C., Lopes, C. C., Lopes, R. S., Miller, W., & Ruiz, G. (2017). Which ballast water management system will you put aboard? Remnant anxieties: A mini-review. Environments, 4(3), 54.