- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

In the realm of corrosion protection, one innovation has been making significant waves: Electronic Titanium Anode Rod. These revolutionary rods are transforming the landscape of electrochemistry, offering unparalleled benefits in terms of longevity, performance, and efficiency.

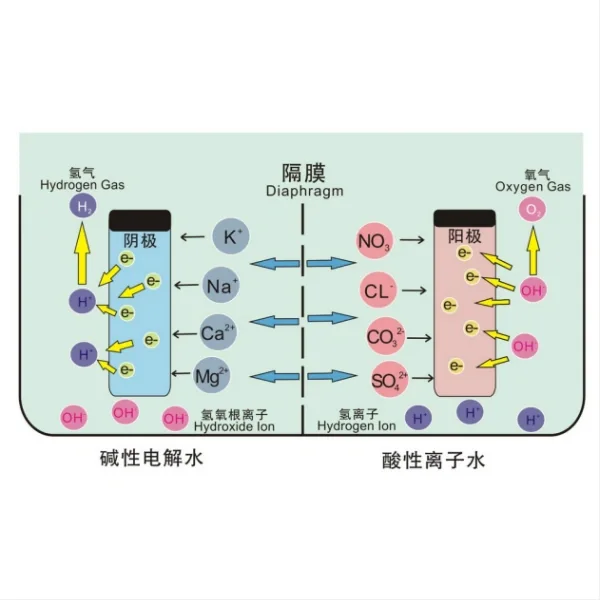

To understand their uniqueness, it's crucial to grasp the fundamental principles behind traditional anode rods and how Electronic Titanium Anode Rods diverge from them. Traditional anode rods, typically made of materials like magnesium or aluminum, work by sacrificing themselves to protect the metal tank from corrosion. While effective to some extent, these rods have limitations in terms of durability and efficiency.

Here's where Electronic Titanium Anode Rods step in with their game-changing approach. Unlike their traditional counterparts, Electronic Titanium Anode Rods utilize advanced electronic principles to actively prevent corrosion rather than simply sacrificing themselves. This proactive approach not only enhances their effectiveness but also extends their lifespan significantly.

The key differentiator lies in the material composition and the mechanism of action. Electronic Titanium Anode Rods are crafted from high-quality titanium, a corrosion-resistant metal renowned for its durability and stability. Coupled with advanced electronic control systems, these rods generate a protective field that inhibits corrosion, ensuring the longevity of the entire system.

How Do Electronic Titanium Anode Rods Enhance System Longevity and Performance?

The benefits of Electronic Titanium Anode Rods extend far beyond mere corrosion protection. By adopting an electronic approach, these rods revolutionize the way systems operate, leading to enhanced longevity and performance.

One of the primary advantages is their ability to adapt dynamically to changing conditions. Traditional anode rods degrade over time, necessitating periodic replacements and maintenance. In contrast, Electronic Titanium Anode Rods maintain their effectiveness throughout their lifespan, offering consistent protection without the need for frequent interventions.

Moreover, Electronic Titanium Anode Rods optimize energy consumption, contributing to improved system efficiency. By precisely controlling the electrochemical processes, these rods minimize energy wastage, resulting in lower operational costs and reduced environmental impact.

Another significant aspect is their versatility and compatibility with various systems. Whether used in water heaters, industrial tanks, or marine applications, Electronic Titanium Anode Rods can be tailored to meet specific requirements, ensuring optimal performance across diverse environments.

Furthermore, the proactive nature of Electronic Titanium Anode Rods minimizes the risk of sudden failures or malfunctions, providing peace of mind to operators and users alike. This reliability translates into increased system uptime and productivity, making them indispensable assets in critical operations.

Where Can Electronic Titanium Anode Rods Be Most Effectively Utilized?

The versatility of Electronic Titanium Anode Rods opens up a myriad of applications across different industries. From residential to industrial settings, these innovative rods find their utility wherever corrosion protection and system longevity are paramount.

In residential water heaters, Electronic Titanium Anode Rods offer a reliable solution to combat the corrosive effects of hard water, extending the lifespan of the heater and ensuring clean, safe water for household use. Similarly, in commercial and industrial settings, such as chemical processing plants or oil refineries, these rods play a crucial role in safeguarding equipment and infrastructure against corrosion damage, thereby preventing costly downtime and repairs.

Marine applications also stand to benefit significantly from Electronic Titanium Anode Rods. Whether in offshore platforms, ships, or seawater desalination plants, corrosion poses a constant threat to maritime assets. By implementing Electronic Titanium Anode Rods, marine operators can effectively mitigate this risk and prolong the service life of critical components, reducing maintenance costs and enhancing operational efficiency.

Moreover, Electronic Titanium Anode Rods hold immense potential in emerging fields such as renewable energy and electric vehicles. As these industries continue to expand, the demand for durable, corrosion-resistant materials will only grow, making Electronic Titanium Anode Rods indispensable for sustainable infrastructure development.

What Are the Key Advantages of Using Electronic Titanium Anode Rods Over Traditional Materials?

The superiority of Electronic Titanium Anode Rod over traditional materials stems from several distinct advantages that set them apart in terms of performance, durability, and cost-effectiveness.

First and foremost, Electronic Titanium Anode Rods offer unparalleled corrosion resistance, thanks to the inherent properties of titanium. Unlike magnesium or aluminum rods that corrode over time, Electronic Titanium Anode Rods remain intact, providing long-lasting protection to the system.

Furthermore, the electronic control systems integrated into Electronic Titanium Anode Rods enhance their efficiency and effectiveness. By actively regulating the electrochemical processes, these rods optimize energy consumption and minimize wastage, resulting in lower operational costs and improved sustainability.

Another key advantage is the minimal maintenance requirements of Electronic Titanium Anode Rods. Unlike traditional rods that need periodic replacements, Electronic Titanium Anode Rods offer hassle-free operation, reducing downtime and maintenance expenses over the long term.

Additionally, Electronic Titanium Anode Rods boast superior versatility and adaptability, making them suitable for a wide range of applications across various industries. Whether installed in residential water heaters or industrial tanks, these rods deliver consistent performance and reliable corrosion protection, ensuring peace of mind for users and operators alike.

Conclusion

In conclusion, Electronic Titanium Anode Rod represent a breakthrough in corrosion protection, offering unmatched durability, performance, and efficiency. By harnessing the power of advanced electronic principles and corrosion-resistant materials, these innovative rods redefine the standards of modern electrochemistry, paving the way for safer, more sustainable infrastructure across diverse industries.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of Electronic Titanium Anode Rod, welcome to contact us: yangbo@tjanode.com.

References:

1. Li, J., Wang, Z., & Zhang, Y. (2020). Advances in Titanium Anode Materials and Technologies for Electrochemical Oxidation. Materials, 13(11), 2476.

2. Saha, A., & Chaudhuri, R. (2019). Corrosion Protection and Surface Treatment of Magnesium Alloys Used in Automotive and Aerospace Components. Surface Engineering in Manufacturing Applications, 245-267.

3. Xie, Y., Zheng, Y., He, S., Li, D., & Zhang, J. (2018). Electrochemical Corrosion Behavior of Titanium Alloys for Marine Applications. Corrosion Science, 133, 96-104.

4. Zhou, S., Xu, W., & Lu, W. (2021). Research Progress of Electronic Control in Corrosion Protection of Titanium Anode Materials. Rare Metals, 40(3), 824-833.

Related Industry Knowledge

- Why MMO Titanium Probe Anodes Are Essential for Advanced Corrosion Protection?

- Why Are MMO Wire Anodes a Game-Changer in Corrosion Protection?

- What Makes MMO Tubular Titanium Anodes a Revolutionary Choice for Electrochemical Applications?

- Crystal Clear Waters: The Power of Titanium Electrodes in Pool Disinfection

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?

- How Does Gold Plating Enhance PCB Performance? An In-Depth Exploration

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What is a DSA Anode and How Does It Work?