- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

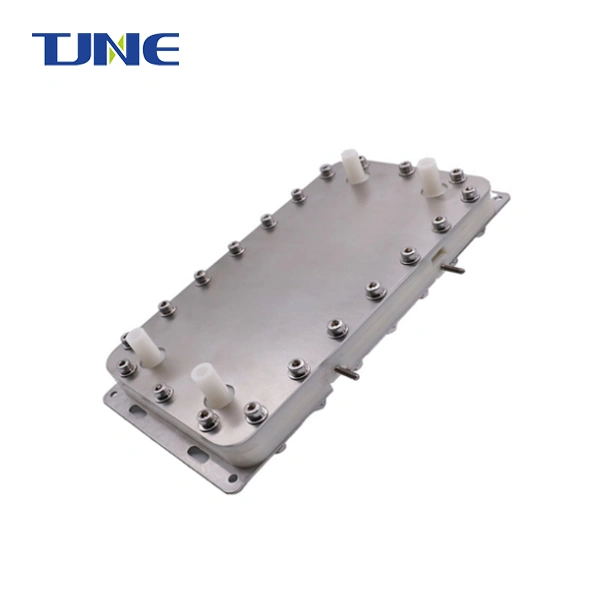

Removal of COD Anode

Product Overview: OD is an indicator that measures the content of organic matter in water. The higher the value, the more serious the water pollution.

Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.

Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.

Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.

As well as refractory organic wastewater and industrial wastewater.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

What is the Removal of COD Anode?

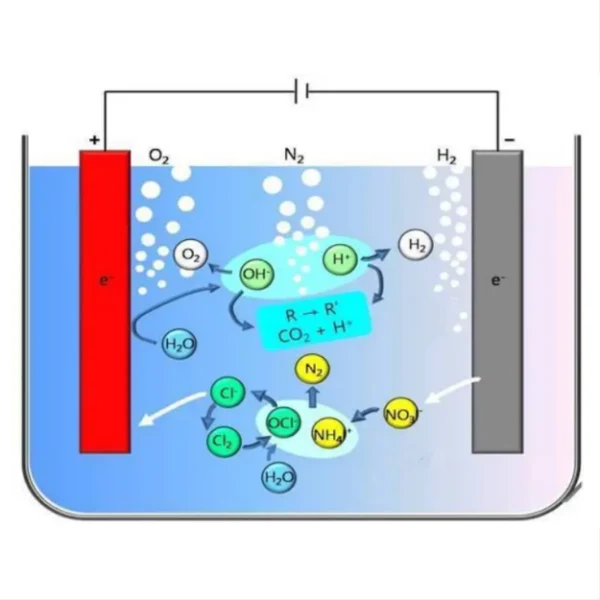

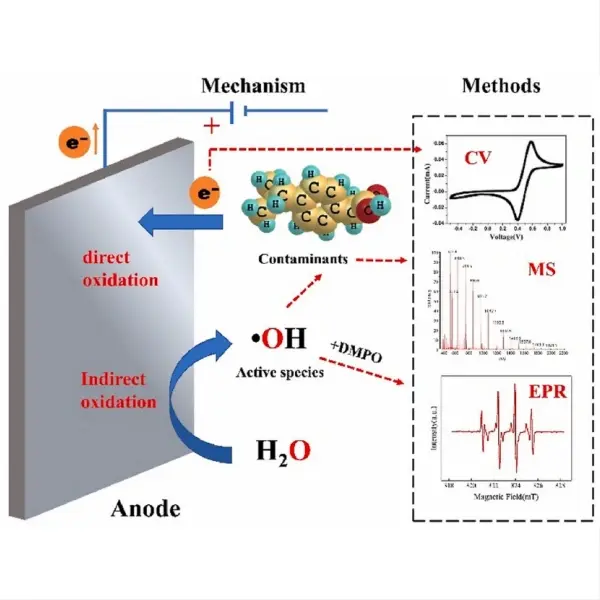

The removal of COD anode is specifically designed to efficiently reduce the COD content in wastewater. It utilizes advanced electrochemical technology to break down organic pollutants, providing a cost-effective and environmentally friendly solution for industries dealing with COD-related issues.

It is an advanced solution for effectively removing COD (Chemical Oxygen Demand) in various industries. With its exceptional performance and reliable operation, it is the ideal choice for wastewater treatment.

System Composition

It consists of the following main components:

-

Anode chamber with specially designed electrodes

-

Cathode chamber for product collection

-

<li.Power supply unit for stable operation

-

Control unit for monitoring and adjustments

Application Areas

Wastewater Treatment Plants: Anodes find practical applications in wastewater treatment plants, where they serve to disintegrate and eliminate both organic and inorganic contaminants. This crucial process effectively lowers the levels of Chemical Oxygen Demand (COD) in the treated water, ensuring that it meets environmental standards before being discharged into the ecosystem or recycled for further use.

Industrial Processes: Across a range of industries, including manufacturing and chemical processing, anodes are employed to address wastewater treatment needs. Their use aids in compliance with stringent environmental regulations by diminishing COD levels in the discharged effluent, contributing to sustainable and responsible industrial practices.

Environmental Remediation: When dealing with instances of environmental contamination or pollution, anodes become valuable tools for the restoration of water sources. By reducing COD and contaminants, these electrochemical devices play a pivotal role in returning affected environments to safe and ecologically compliant conditions.

Water Recycling: Anodes are instrumental in the treatment of water destined for recycling purposes. They play a pivotal role in ensuring that the recycled water meets established quality standards by effectively reducing COD levels, thus facilitating its safe and efficient reuse.

Desalination: In the realm of desalination, anodes have a significant role to play. They are used in treating brackish or saline water sources, effectively reducing COD levels. This transformation renders the water suitable for an array of purposes, making it a versatile tool in the production of freshwater from saline sources.

Frequently Asked Questions (FAQ)

-

Can this system handle high volumes of wastewater?

Yes, the Removal of the COD Anode system can handle a large capacity of wastewater. It is available in various models with different capacities to meet specific requirements.

-

How long does it take to remove COD from wastewater?

The removal time depends on the initial COD concentration and the desired reduction level. It is recommended to conduct a feasibility study and seek professional advice for accurate estimations.

-

Is there any maintenance required for the system?

Regular maintenance is necessary to ensure optimal performance and longevity of the system. The manufacturer provides detailed maintenance guidelines and offers complete after-sales services to assist customers.

In conclusion, TJNE is a professional manufacturer and supplier of Removal of COD Anode, offering a high level of technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, secure packaging, and support for testing. If you are considering your Removal of COD Anode, please feel free to contact us at yangbo@tjanode.com

YOU MAY LIKE

DSA ANODE

Product name: DSA ANODE<br>Product Overview: An anode material used in electrochemical processes<br>The main component of the product: is Ti (titanium).<br>Product advantages: It has excellent corrosion resistance, low oxygen evolution overvoltage, and does not pollute cathode products.<br> It is expected to replace the traditional Pb anode and achieve energy saving.<br>Application areas: metal electrowinning, electroplating industry, microbial fuel cells, electrochemical energy storage systems, environmental protection fields, etc.<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

Nel Alkaline Electrolyser

High performance. The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard. The gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Wastewater Disinfection and Oxidation Anode

Product name: Wastewater Disinfection and Oxidation Anode<br>Product Overview: Titanium anodes are improved through coating performance to improve electrolysis wastewater treatment effects.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Removal of ammonia nitrogen Anode

Product Overview: Ammonia nitrogen is a pollutant in water bodies and is harmful to the human body and the environment, so measures need to be taken to remove it.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

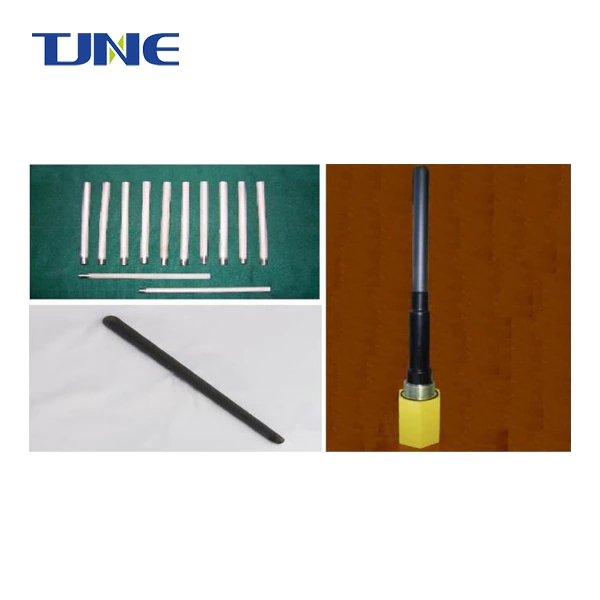

MMO Titanium Probe Anode

Product name: MMO Titanium Probe Anode<br>Product overview: The main body of the probe-type anode is an MMO rod-shaped anode, which adopts an advanced sealing system.<br>It consists of a water stop valve, an O-ring seal, and epoxy resin. After sealing, it can be used in high-pressure working conditions.<br>Advantages and features: Easy to install, can be installed directly through the wall from the outside;<br>Small size, lightweight, stable performance, and strong corrosion resistance;<br>The current density is very low, the power saving performance is excellent, and it has very stable performance;<br>Improve the coating formula and production process, the coating and the substrate are firmly bonded, and the service life is longer;<br>Applicable scenarios: Probe-type anodes are mainly used in impressed current cathodic protection systems on the inner surfaces of pipelines, water tanks, pressure vessels, etc.<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

MMO Wire Anode

Product name: MMO Wire Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, anti-corrosion, and other fields.<br>Titanium anodes are widely used as a method in impressed current protection methods;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments such as seawater, fresh water, soil media, etc.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

Alkaline Water Electrolyser

Acid water+alkaline water output<br> Multi-stage diaphragm electrolysis<br> PH value of Acidic water:1.5-3;<br> PH value of Alkaline water:12-13<br> working life>5000h<br> By electrolyzing salt water, the anode produces acidic water and the cathode produces alkaline water

View More

electrodeposited titanium electrode for cobalt

Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More