- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ion membrane electrolyzer

Working life>5000 h

Applications:

Animal husbandry disinfection

Disinfection of fruits and vegetables

Deodorization

Medical equipment disinfection

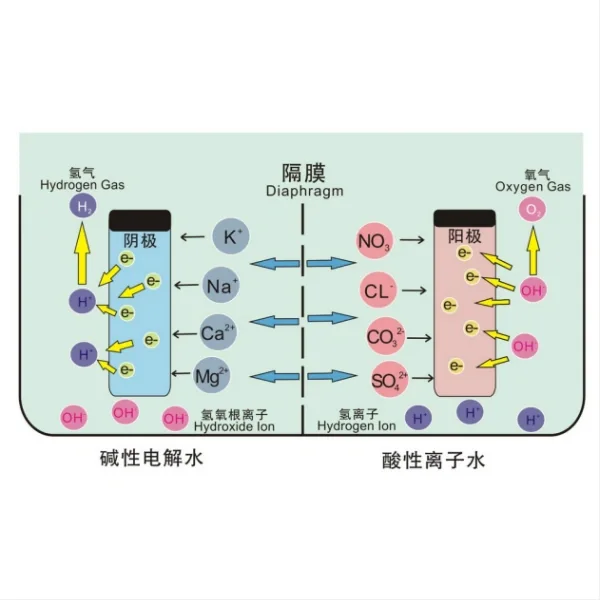

What Is Ion Membrane Electrolyzer?

The Ion membrane electrolyzer is a cutting-edge technology used for water electrolysis to produce hydrogen gas. It is designed with advanced features to ensure efficient and reliable performance. This electrolyzer is widely used in various industries.

The Ion membrane electrolyzer utilizes an ion exchange membrane to separate the anode and cathode chambers in the electrolytic cell. When an electric current passes through the cell, water motes are resolved into hydrogen and oxygen feasts. The ion exchange membrane allows the passage of protons from the anode to the cathode while blocking the migration of other species, icing chastity hydrogen products. This process is known as electrolysis and is grounded on the principles of electrochemistry.

System Components and Structure:

The Ion membrane electrolyzer consists of several key components, including:

-

Anode compartment: where water oxidation and oxygen gas release occur.

-

Cathode compartment: where hydrogen evolution takes place.

-

Ion exchange membrane: separates the anode and cathode compartments, only allowing the passage of protons.

-

Electrodes: facilitate the electrochemical reactions at the anode and cathode.

-

Power supply: provides the necessary electric current for electrolysis.

The system is compact, highly efficient, and easy to operate. Its robust construction ensures durability and long service life.

1. Working principle:

The ion exchange membrane has special permselectivity, allowing only cations to pass through and preventing anions and gases from passing through. In an ion membrane electrolyzer, the anode and cathode are placed on both sides of the ion exchange membrane. After electricity is applied, an oxidation reaction occurs at the anode and a reduction reaction occurs at the cathode. Due to the action of the ion exchange membrane, cations (such as hydrogen ions) migrate through the ion membrane toward the cathode, while anions (such as chloride ions) migrate toward the anode. In this way, chlorine gas is produced in the anode region, and hydrogen gas is produced in the cathode region.

2. Main process:

(1) Inject refined saturated brine into the anode chamber;

(2) Inject pure water into the cathode chamber (a certain amount of sodium hydroxide solution can be added);

(3) After electricity is applied, water decomposes to produce hydrogen and sodium hydroxide;

(4) Hydrogen is produced in the anode chamber and chlorine is produced in the cathode chamber;

(5) The ion exchange membrane prevents the mixing of hydrogen and chlorine to avoid explosion;

(6) The electrolyzed light salt water is exported from the anode chamber and is recycled after adding salt to increase the concentration.

Ion membrane electrolyzers are widely used in hydrogen production, chlorine production, alkali production and other fields. It has the advantages of high efficiency, environmental protection, safety, and other advantages, and can achieve green production.

Features :

-

High hydrogen production rate with excellent purity

-

Compact and efficient design

-

Long service life and durability

-

Easy operation and maintenance

-

Environmentally friendly with zero emissions

Applications:

The Ion membrane electrolyzer finds applications in various industries, including:

-

Hydrogen fuel production for fuel cell vehicles

-

Chemical synthesis and manufacturing processes

-

Energy storage and grid balancing

-

Electronics and semiconductor manufacturing

FAQ:

Q: What is the lifespan of the ion exchange membrane?

A: The ion exchange membrane typically lasts for several years, depending on the operating conditions and maintenance.

Q: Is the electrolyzer suitable for continuous operation?

A: Yes, the electrolyzer is designed for continuous operation, offering high reliability and stability.

Q: Can the system be customized for specific requirements?

A: Yes, we provide customization options to meet the specific needs of our customers.

Feel free to contact us at yangbo@tjanode.com if you have any further questions or if you are interested in purchasing your own Ion membrane electrolyzer. We are a professional manufacturer and supplier, offering strong technical expertise and comprehensive after-sales service.

In conclusion, the Ion membrane electrolyzer is a state-of-the-art hydrogen production technology that offers high efficiency, reliability, and purity. Its compact design, advanced features, and wide applications make it an ideal choice for various industries. Choose TJNE for all your Ion membrane electrolyzer needs, and experience outstanding performance and service.

YOU MAY LIKE

Copper Foil Anode

Product name: Copper Foil Anode<br>Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.<br>Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.<br>Technical advantages:<br>Long life: ≥40000kAh m-2 (or 8 months)<br>High uniformity: coating thickness deviation ±0.25μm<br>High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V<br>Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Electrode-diaphragm assembly for alkaline water electrolysis

Product name: Electrode-diaphragm assembly for alkaline water electrolysis<br>Product overview: flow channel design, processing, anti-corrosion coating processing, and gas diffusion layer coating processing of titanium bipolar plates in PEM electrolyzers.<br>Product features: No need to open a mold, the plate surface is highly flat, and the front and back plate type flow channels can achieve inconsistent graphics.<br>Highlights: high processing precision, low internal resistance of the coating, strong bonding force, and low surface contact resistance<br>Applicable scenarios: Bipolar plate processing design and diffusion layer design inside PEM electrolyzer.<br>Application conditions: PEM electrolyzer.<br>Product after-sales and services: bipolar plate coating processing and design, diffusion layer coating processing.<br>

View MoreElectrolyzers.webp)

Polymer Electrolyte Membrane(PEM)Electrolyzers

High performance: The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard, and the gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Nel Alkaline Electrolyser

High performance. The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard. The gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Modular Membrane Electrolyser

Product overview: It is a high-efficiency electrolysis equipment with a modular design.<br>Product advantages: modular design, high efficiency and energy saving, high stability, anti-pollution performance, automatic control, and easy maintenance.<br>Application areas: water treatment, hydrogen and oxygen production, environmental protection, chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide. <br>

View More

DSA Coating Titanium Anode

DSA-coated titanium anodes are coated with precious metal oxides on the surface, such as ruthenium oxide (RuO2) and titanium oxide (TiO2). This anode material has many advantages in the electrochemical process, such as excellent corrosion resistance, low oxygen evolution overvoltage, and no contamination of cathode products.

View More

electrodeposited titanium electrode for nickel-cobalt

Product name: electrodeposited titanium electrode for nickel-cobalt<br>Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More

PCB VCP DC Copper Plating DSA

Product name: PCB VCP DC Copper Plating<br>Product Overview: Plating materials used in printed circuit board (PCB) manufacturing processes.<br>Product features: stable dimensions, firm coating, corrosion resistance, long service life; <br>effectively reduces tank voltage, a significant energy-saving effect; <br>ultra-low consumption can reduce production costs.<br>Advantages and highlights: long life (can be customized according to customer requirements);<br>low energy consumption, and high electrocatalytic activity.<br>Conditions of use: electrolyte CuSO4·5H20 H2SO4; temperature 20℃-45℃; current density 100-3000A/m2DC;<br>Applicable scenarios: VCP line/horizontal line copper plating, via/fill/pulse copper plating, soft/hard board plating, semiconductor substrate plating;<br>After-sales service: Providing timely and high-quality new anode manufacturing and old anode repainting services worldwide.<br>

View More