- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High concentration sodium hypochlorite generator (diaphragm electrolysis)

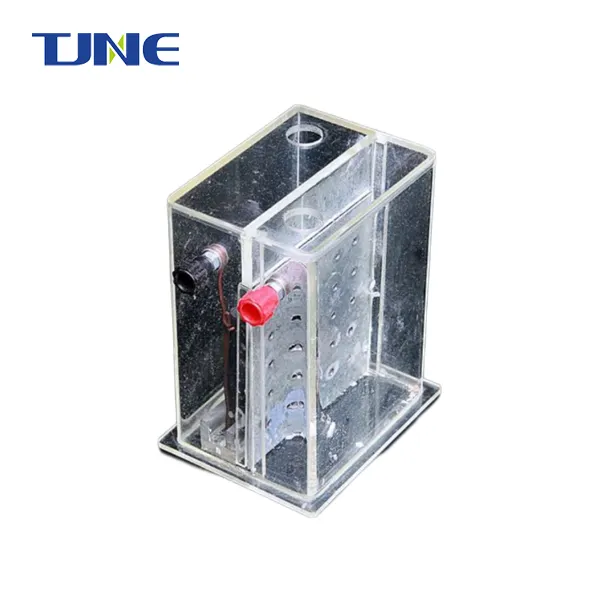

High concentration sodium hypochlorite generator (diaphragm electrolysis) Product Details:

The electrolytic high-concentration sodium hypochlorite generator is a device that uses the principle of electrolysis to prepare high-concentration sodium hypochlorite solution. High-concentration sodium hypochlorite has strong oxidizing and disinfecting effects and is widely used in water treatment, environmental protection, medical, and other fields. The following is the working principles, characteristics, and applications of electrolytic high-concentration sodium hypochlorite generator:

working principle:

The electrolytic high-concentration sodium hypochlorite generator generates sodium hypochlorite solution by electrolyzing salt water. The equipment mainly consists of a brine refining device, electrolyzer, control system, etc. During the working process, the salt water enters the electrolytic tank after pretreatment. In the electrolytic cell, through the action of direct current between the cathode and anode, the chloride ions and hydroxide ions in the saltwater undergo an electrolysis reaction to generate a high-concentration sodium hypochlorite solution.

System Composition and Structure:

The diaphragm electrolysis consists of a power supply, an electrolyzer, a diaphragm cell, and a control system. The electrolyzer is equipped with electrodes and a diaphragm to facilitate the electrolysis process. The control system ensures precise control over various operating parameters, such as current, voltage, and temperature. The generator is compact, easy to install, and requires minimal maintenance.

Performance Parameters

| Parameter | Value |

|---|---|

| Available Concentration Range | 1-15% |

| Production Capacity | 100-1000 kg/day |

| Power Consumption | 3-30 kW/hour |

| Chlorine Production Efficiency | 95-98% |

Economic Indicators

| Economic Indicator | Value |

|---|---|

| Life Span | 10-15 years |

| Operating Cost | Low |

| Return on Investment | High |

Features:

1. High efficiency: The electrolytic high-concentration sodium hypochlorite generator adopts advanced electrolysis technology to make the concentration of sodium hypochlorite solution reach a higher level and achieve better disinfection effect.

2. High safety: The raw material used in the equipment is table salt, which is safer than chlorine dioxide generators and ozone generators.

3. Low cost: Compared with other disinfection equipment, the operating cost of an electrolytic high-concentration sodium hypochlorite generator is low.

4. Easy to operate: The equipment is easy to operate, has strong controllability and strong adaptability.

5. Environmental protection: No harmful by-products are produced during the electrolysis process, which meets the requirements of green environmental protection.

Applications:

The High Concentration Sodium Hypochlorite Generator is widely used in various industries, including water treatment, wastewater treatment, disinfection of surfaces and equipment, food processing, and swimming pool sanitation.

1. Water treatment: used for disinfection of drinking water, disinfection of industrial water cooling circulation systems, disinfection of swimming pool water, etc.

2. Environmental protection: used for sewage treatment, wastewater disinfection, etc.

3. Medical treatment: used for disinfection of hospital sewage, medical equipment, etc.

4. Agriculture: used for water disinfection in planting and breeding industries.

5. Food processing: used for disinfection and preservation during food processing.

In short, the electrolytic high-concentration sodium hypochlorite generator has the advantages of high efficiency, safety, economy, and environmental protection, and is suitable for disinfection in various occasions. When purchasing an electrolytic high-concentration sodium hypochlorite generator, please pay attention to product quality, performance and service, and choose the appropriate equipment based on your own needs.

FAQ :

-

Q: How long does it take to install the generator?

-

A: The installation time depends on the specific model and site requirements, but it typically takes a few days.

-

Q: Can the generator be customized to meet specific production demands?

-

A: Yes, we offer customization options to ensure the generator meets your specific requirements.

-

Q: What kind of maintenance is required for the generator?

-

A: The generator requires regular inspection and cleaning of electrodes and the diaphragm. A detailed maintenance schedule is provided with the product.

Contact Us:

If you are considering purchasing your own High Concentration Sodium Hypochlorite Generator, feel free to contact us at yangbo@tjanode.com. We are a professional manufacturer and supplier with strong technical expertise and excellent after-sales service. We provide complete certification and testing reports, fast delivery, secure packaging, and support for testing. Choose TJNE for all your sodium hypochlorite generator needs.

YOU MAY LIKE

Ballast water titanium electrode

1.Chlorine precipitation anode life >5 years,cathode life >20 years<br>2.Generation of effective chlorine concentration: ≥9000 ppm<br> 3.Salt consumption: ≤2.8 kg/ kg·Cl,DC power consumption: ≤3.5 kwh/kg·Cl

View More

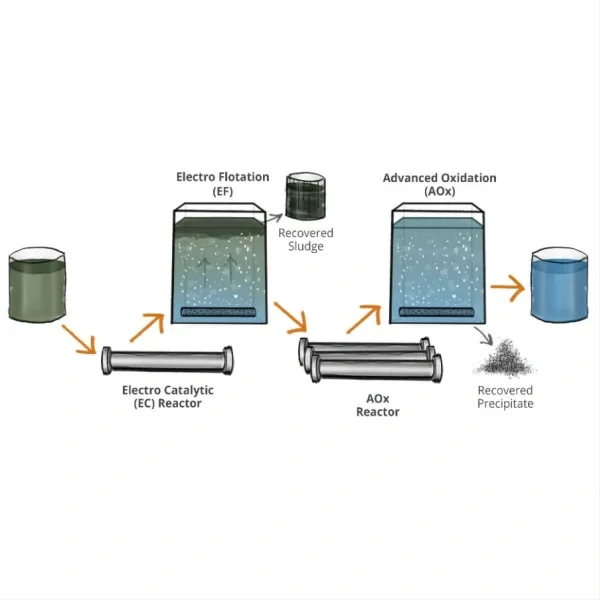

Electrochemical organic matter decomposition equipment

Product name: Electrochemical organic matter decomposition equipment<br>Product Overview: It is a device that uses electrochemical principles to decompose organic matter.<br>Components: electrolyzer, plates, electrolyte, DC power supply, control system, etc.<br>Product features: high decomposition efficiency, simple operation, no secondary pollution, strong adaptability, etc.<br>Applicable scenarios: Suitable for the treatment of all types of organic wastewater.<br>Application conditions: Appropriate electrochemical organic matter decomposition equipment needs to be selected based on wastewater characteristics and treatment requirements.<br>And adjust operating parameters to achieve optimal processing results.<br>Product after-sales and service: Provide timely and high-quality equipment debugging and installation equipment globally.<br>

View More

NaCl diaphragm electrolyzer

View More

Brine Electrolysis Sodium Hypochlorite Generator

Product Name: Brine Electrolysis Sodium Hypochlorite Generator<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine, and generates sodium hypochlorite through an oxidation-reduction reaction.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: used in the chemical industry, pharmaceutical, water treatment, and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Brine Electrolysis Equipment

Product name: Brine Electrolysis Equipment<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and small equipment footprint.<br>Application fields: used in chemical industry, pharmaceutical, water treatment and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Membrane electrolysis for NaCl

Product name: Membrane electrolysis for NaCl<br>Product overview: It is a device that uses membrane electrolysis technology to prepare sodium chloride.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: water treatment, hydrogen and oxygen production, environmental protection, and chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Modular Membrane Electrolyser

Product overview: It is a high-efficiency electrolysis equipment with a modular design.<br>Product advantages: modular design, high efficiency and energy saving, high stability, anti-pollution performance, automatic control, and easy maintenance.<br>Application areas: water treatment, hydrogen and oxygen production, environmental protection, chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide. <br>

View More

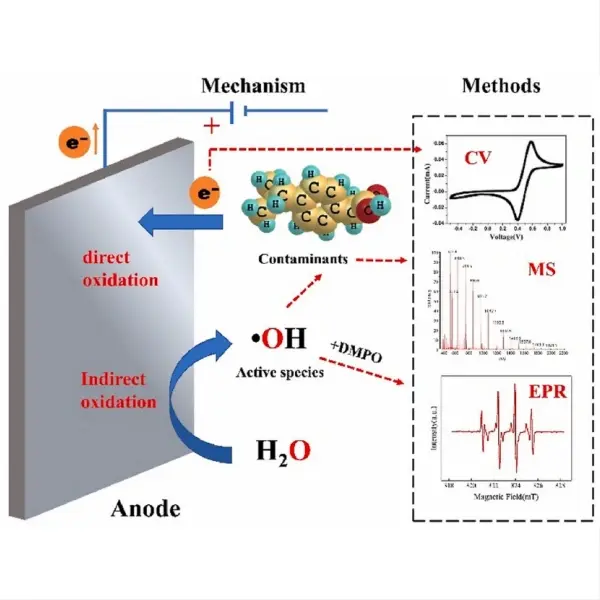

Wastewater Disinfection and Oxidation Anode

Product name: Wastewater Disinfection and Oxidation Anode<br>Product Overview: Titanium anodes are improved through coating performance to improve electrolysis wastewater treatment effects.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More