- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electrode-diaphragm assembly for alkaline water electrolysis

Product overview: flow channel design, processing, anti-corrosion coating processing, and gas diffusion layer coating processing of titanium bipolar plates in PEM electrolyzers.

Product features: No need to open a mold, the plate surface is highly flat, and the front and back plate type flow channels can achieve inconsistent graphics.

Highlights: high processing precision, low internal resistance of the coating, strong bonding force, and low surface contact resistance

Applicable scenarios: Bipolar plate processing design and diffusion layer design inside PEM electrolyzer.

Application conditions: PEM electrolyzer.

Product after-sales and services: bipolar plate coating processing and design, diffusion layer coating processing.

Electrode-diaphragm assembly for alkaline water electrolysis is a critical component used in alkaline water electrolysis systems. It's responsible for easing the electrochemical responses involved in the electrolysis process, converting water into hydrogen and oxygen feasts. This product is designed to give effective and dependable electrolysis performance, making it suitable for colorful artificial operations.

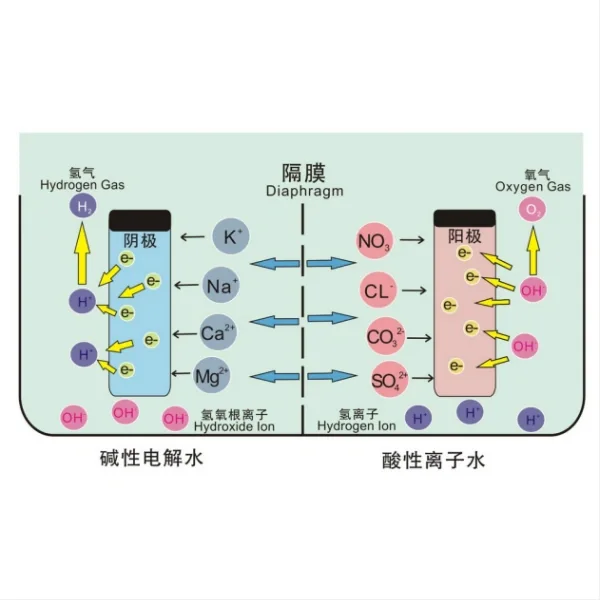

Working Principle:

The electrode-diaphragm assembly consists of two electrodes( anode and cathode) separated by a diaphragm. When an electric current is applied, water motes at the anode are oxidized, generating oxygen gas and appreciatively charged hydroxide ions. Simultaneously, at the cathode, hydrogen gas, and negatively charged hydroxide ions are produced through reduction reactions. The diaphragm helps to separate the gases and prevent their recombination, ensuring high purity gas production.

System Composition:

The electrode-diaphragm assembly comprises high-quality electrodes made from specialized materials, such as titanium coated with platinum or other catalysts. The diaphragm is typically made of ion-exchange membranes or porous materials, ensuring selective ion transport. These components are securely attached to a support structure to maintain proper alignment and stability during operation.

Features and Characteristics

-

High efficiency and reliability

-

Excellent gas separation performance

-

Durable and corrosion-resistant materials

-

Precise and consistent gas production

-

Easy installation and maintenance

Performance Parameters

| Parameter | Value |

|---|---|

| Operating Voltage | 4 - 6 V |

| Gas Production Rate | 100 - 500 cm3/min |

| Electrode Lifespan | 10,000 - 20,000 hours |

| Gas Purity | 99.9% |

Economic Indicators

| Indicator | Value |

|---|---|

| Cost Savings | Up to 30% compared to other electrolysis methods |

| Energy Efficiency | High |

| Return on Investment | Quick |

Applications

The electrode-diaphragm assembly for alkaline water electrolysis is widely used in industries such as chemical processing, hydrogen production, metal refining, and energy storage. It can be employed for large-scale hydrogen production, hydrogen fuel cell applications, and experimental setups in research laboratories.

FAQ:

-

Q: Is the electrode-diaphragm assembly compatible with different types of electrolysis systems?

-

Q: How often does the assembly need to be replaced?

A: Yes, it can be customized to fit various electrolysis setups based on specific requirements.

A: The electrode lifespan ranges from 10,000 to 20,000 hours, depending on operating conditions.

Contact :

If you are interested in our electrode-diaphragm assembly for alkaline water electrolysis, please feel free to contact us at yangbo@tjanode.com. We are a professional manufacturer and supplier with strong technical expertise, providing comprehensive one-stop after-sales service, complete certification and testing reports, fast delivery, and secure packaging. We also offer support for testing and evaluation. Choose TJNE for your alkaline water electrolysis needs!

YOU MAY LIKE

High efficiency Copper Dissolution Tank

Product name: High efficiency Copper Dissolution Tank<br>Product Overview: It is a device used to dissolve copper in the copper foil production process. Its main function is to dissolve copper ions in water to form an electrolyte.<br>Product advantages: efficient dissolution, stable operation, environmental protection and energy saving, easy maintenance, and high safety.<br>Technical advantages:<br>1. Maximize the copper-melting reaction speed and heat release without steam heating.<br>The negative pressure air formed in the tank is self-primed to reduce energy consumption.<br>2. The self-developed system improves the copper dissolving efficiency, and the copper dissolving efficiency can reach 260kg/h.<br>3. The guaranteed copper amount is ≤35 tons (the industry average is 80~90 tons), reducing system costs.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Ballast water titanium electrode

1.Chlorine precipitation anode life >5 years,cathode life >20 years<br>2.Generation of effective chlorine concentration: ≥9000 ppm<br> 3.Salt consumption: ≤2.8 kg/ kg·Cl,DC power consumption: ≤3.5 kwh/kg·Cl

View MoreElectrolyzers.webp)

Polymer Electrolyte Membrane(PEM)Electrolyzers

High performance: The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard, and the gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Nel Alkaline Electrolyser

High performance. The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard. The gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Ion membrane electrolyzer

Acidized water electrolysis tank ( diaphragm)Effective chlorine concentration:10-120ppm<br> Working life>5000 h<br> Applications:<br> Animal husbandry disinfection<br> Disinfection of fruits and vegetables<br> Deodorization<br> Medical equipment disinfection<br>

View More

Brine Electrolysis Sodium Hypochlorite Generator

Product Name: Brine Electrolysis Sodium Hypochlorite Generator<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine, and generates sodium hypochlorite through an oxidation-reduction reaction.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: used in the chemical industry, pharmaceutical, water treatment, and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Brine Electrolysis Equipment

Product name: Brine Electrolysis Equipment<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and small equipment footprint.<br>Application fields: used in chemical industry, pharmaceutical, water treatment and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

electrodeposited titanium electrode for zinc

Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.<br>The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.<br>Product features: corrosion resistance, minimal lead dissolution, good electrical conductivity, and the ability to pass large currents.<br>Product advantages: Compared with traditional lead anodes, it can increase by 2%, reduce lead dissolution rate by 99%, extend service life, and reduce costs.<br>Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.<br>

View More