- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

In the realm of corrosion protection, the search for efficient and long-lasting solutions has been ongoing. Traditional methods often fall short in terms of durability and effectiveness. However, a revolutionary technology has emerged in the form of MMO Wire Anodes, offering unparalleled performance in combating corrosion.

Efficiency: MMO wire anodes provide efficient corrosion protection by delivering a constant current density over a large surface area. This ensures uniform protection and minimizes the risk of localized corrosion.

Longevity: MMO wire anodes have a long service life compared to traditional sacrificial anodes. They are highly resistant to corrosion themselves and can withstand harsh environments, resulting in extended protection for structures and equipment.

Flexibility: MMO wire anodes can be easily customized to fit various shapes and sizes, making them suitable for a wide range of applications. They can be installed in tight spaces or irregular surfaces, providing flexibility in design and installation.

Low Maintenance: Once installed, MMO wire anodes require minimal maintenance. Unlike sacrificial anodes, which need to be replaced periodically, MMO wire anodes offer long-term, maintenance-free corrosion protection.

Environmentally Friendly: MMO wire anodes produce negligible byproducts during the corrosion protection process, making them environmentally friendly. They do not release harmful substances into the surrounding environment, contributing to sustainable corrosion control practices.

How Do MMO Wire Anodes Offer Superior Performance and Durability?

MMO (Mixed Metal Oxide) Wire Anodes represent a significant advancement in corrosion prevention due to their unique composition and structure. Unlike conventional sacrificial anodes, MMO Wire Anodes utilize a specialized coating comprising mixed metal oxides. This coating, applied onto a titanium substrate, enhances the anode's resistance to corrosion, ensuring prolonged effectiveness in harsh environments.

The key to MMO Wire Anodes' exceptional performance lies in their ability to generate a protective current that mitigates corrosion on metallic structures. This process, known as cathodic protection, involves the transfer of electrons from the anode to the metal surface, effectively neutralizing corrosive reactions. With MMO Wire Anodes, this protective current is not only sustained over extended periods but also remains consistent, ensuring reliable corrosion prevention.

Furthermore, MMO Wire Anodes boast remarkable durability, capable of withstanding corrosive elements such as seawater, soil, and industrial chemicals. Their robust construction and corrosion-resistant coating make them ideal for various applications, including offshore structures, pipelines, storage tanks, and reinforced concrete.

Where Can MMO Wire Anodes Be Most Effectively Utilized?

The versatility of MMO Wire Anodes makes them suitable for a wide range of environments where corrosion poses a significant threat. Industries such as oil and gas, marine, infrastructure, and chemical processing can benefit immensely from the corrosion protection offered by MMO Wire Anodes.

Offshore platforms and subsea pipelines, for instance, are constantly exposed to corrosive seawater, making them prime candidates for MMO Wire Anode installations. Similarly, storage tanks containing aggressive chemicals or buried pipelines traversing corrosive soil environments can greatly benefit from the long-term protection provided by MMO Wire Anodes.

Moreover, the use of MMO Wire Anodes in reinforced concrete structures offers a sustainable solution to combat corrosion-induced deterioration. By incorporating MMO Wire Anodes into concrete structures such as bridges, parking garages, and marine structures, the service life of these assets can be significantly extended, reducing maintenance costs and enhancing structural integrity.

What Are the Installation and Maintenance Advantages of Using MMO Wire Anodes?

One of the significant advantages of MMO Wire Anodes is their ease of installation and minimal maintenance requirements. Unlike traditional sacrificial anodes that often necessitate frequent replacement, MMO Wire Anodes have a lifespan of several decades, reducing the need for costly and disruptive maintenance interventions.

The lightweight and flexible nature of MMO Wire Anodes facilitate straightforward installation, even in challenging environments. Whether retrofitting existing structures or integrating into new construction projects, MMO Wire Anodes can be easily tailored to meet specific corrosion protection requirements.

Furthermore, the low maintenance nature of MMO Wire Anodes translates to significant cost savings over the asset's lifespan. With minimal upkeep requirements, operators can allocate resources more efficiently, focusing on core operations rather than combating corrosion-related issues.

Conclusion

In conclusion, MMO Wire Anodes represent a paradigm shift in corrosion protection, offering unparalleled performance, durability, and cost-effectiveness. Their ability to provide long-term protection in diverse environments makes them indispensable assets across various industries. By harnessing the power of MMO Wire Anodes, organizations can safeguard their critical infrastructure, ensuring operational efficiency and longevity.

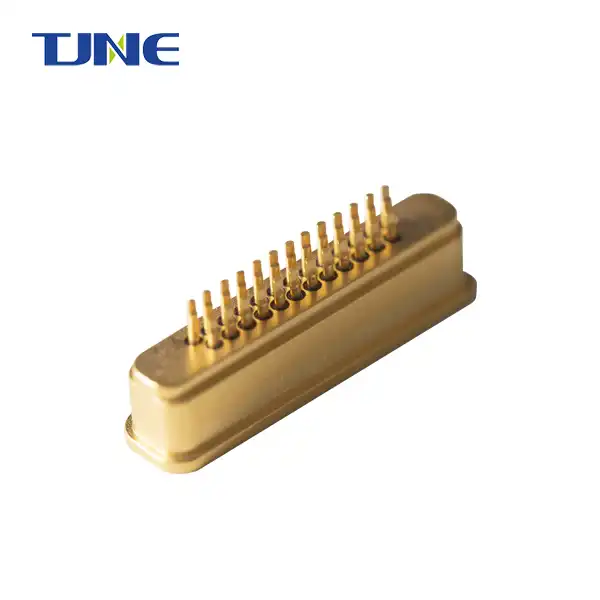

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of MMO Wire Anode, welcome to contact us: yangbo@tjanode.com.

References

1. Fontana, M.G., and Greene, N.D. "Corrosion Engineering." McGraw-Hill Education, 2006.

2. Revie, R.W., and Uhlig, H.H. "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." John Wiley & Sons, 2008.

3. ASTM G193-03. "Standard Terminology and Acronyms Relating to Corrosion." ASTM International, 2014.

4. Postlethwaite, J., and Mears, D.C. "The Use of MMO Coated Titanium Anodes in Cathodic Protection Systems." Materials Performance, vol. 29, no. 10, pp. 45-49, 1990.

Related Industry Knowledge

- How Do Oxidation Anodes Contribute to Effective Wastewater Disinfection?

- Unlocking the Potential: The Science and Applications of Acidic Electrolytic Water

- The Protective Power of MMO Ribbon Anodes: A Deep Dive into Cathodic Protection

- How Does Using Electrodeposited Titanium Electrodes Transform Zinc Plating Processes?

- Why Should You Consider Titanium Electrodes for Copper Plating?

- How Does Gold Plating Enhance PCB Performance? An In-Depth Exploration

- What Industries Rely on DSA Anodes for Electrochemical Processes?

- What Is a Chlorine Generator Electrolyzer and How Does It Operate?

- What is a DSA Anode and How Does It Work?

- What are DSA anodes?