- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nel Alkaline Electrolyser

Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

What IsNel Alkaline Electrolyser?

The Nel Alkaline Electrolyser is a high-quality electrolysis system that utilizes advanced technology to produce hydrogen gas through the electrolysis of water. This product is designed to give a dependable and effective result for colorful artificial operations.

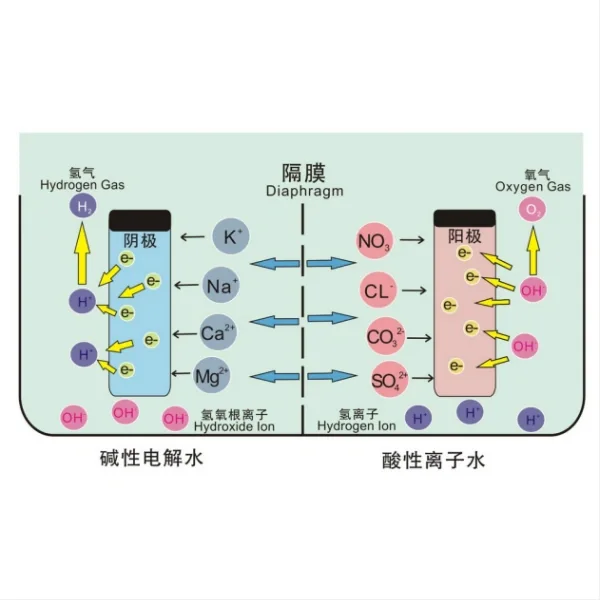

Working Principle :

The Nel Alkaline Electrolyser operates grounded on the principle of electrolysis, where water( H2O) is resolved into hydrogen( H2) and oxygen( O2) feasts using an electrochemical process. This electrolysis occurs within a specially designed alkaline electrolyte result that facilitates the response.

Advantage highlights:

Intensive design: The container design adapts to harsh outdoor environments, supports interface-type installation and high current density design, and the volume of electrolyzers is significantly smaller than conventional ones. Separation frame: many-to-one structure, improves equipment pipeline utilization and reduces investment costs;

Intelligent: It can realize intelligent operation and maintenance in the cloud and collect data to feed back equipment operation.

Safe and reliable: The equipment adopts intrinsically safe explosion-proof, and the system layer is designed to start and stop with one click and stop by mistake to maximize the safety of personnel.

System Composition:

The Nel Alkaline Electrolyser is composed of high-quality materials to ensure durability and efficient performance. It includes electrodes made of specialized alloys, an alkaline electrolyte solution tank, a power supply unit, and a control system for monitoring and adjusting the electrolysis process. The system is also equipped with safety features to prevent any potential hazards.

Features:

-

High-quality materials for durability

-

Advanced alkaline electrolysis technology

-

Efficient hydrogen production

-

Reliable and safe operation

-

Easy to install and maintain

Applications:

The Nel Alkaline Electrolyser has a wide range of applications, including:

-

Hydrogen fuel production

-

Chemical industry

-

Energy storage

-

Power-to-gas systems

Application conditions: Product supply of photovoltaic modules, power station EPC, and hydrogen production equipment for the entire hydrogen production process, green electricity + green hydrogen, no carbon emissions in the entire process

Product after-sales and service: Provide timely and high-quality equipment debugging and installation equipment globally.

FAQ:

1. How long is the warranty period?

The warranty period for the Nel Alkaline Electrolyser is XX months from the date of purchase.

2. Can the system be customized for specific requirements?

Yes, our team can provide customization options based on specific customer requirements.

Contact Us:

If you are interested in purchasing your own Nel Alkaline Electrolyser, please feel free to contact us at yangbo@tjanode.com. Our team at TJNE is a professional manufacturer and supplier of Nel Alkaline Electrolysers. We provide strong technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, and secure packaging. We support product testing and offer reliable solutions for your hydrogen production needs.

YOU MAY LIKE

DSA ANODE

Product name: DSA ANODE<br>Product Overview: An anode material used in electrochemical processes<br>The main component of the product: is Ti (titanium).<br>Product advantages: It has excellent corrosion resistance, low oxygen evolution overvoltage, and does not pollute cathode products.<br> It is expected to replace the traditional Pb anode and achieve energy saving.<br>Application areas: metal electrowinning, electroplating industry, microbial fuel cells, electrochemical energy storage systems, environmental protection fields, etc.<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

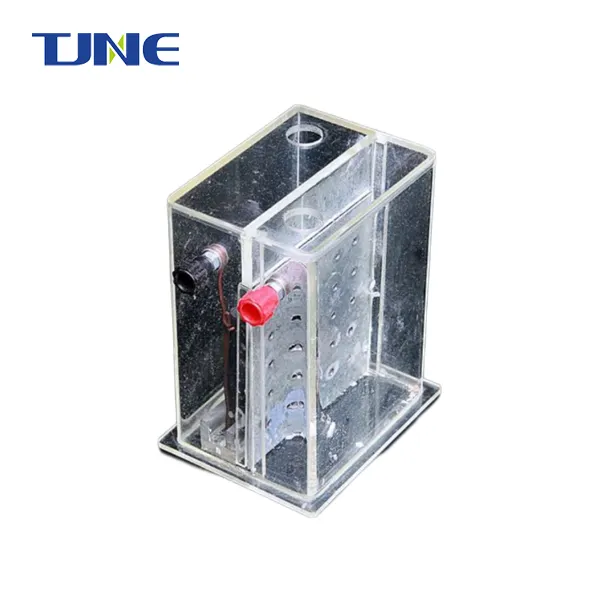

Electrode-diaphragm assembly for alkaline water electrolysis

Product name: Electrode-diaphragm assembly for alkaline water electrolysis<br>Product overview: flow channel design, processing, anti-corrosion coating processing, and gas diffusion layer coating processing of titanium bipolar plates in PEM electrolyzers.<br>Product features: No need to open a mold, the plate surface is highly flat, and the front and back plate type flow channels can achieve inconsistent graphics.<br>Highlights: high processing precision, low internal resistance of the coating, strong bonding force, and low surface contact resistance<br>Applicable scenarios: Bipolar plate processing design and diffusion layer design inside PEM electrolyzer.<br>Application conditions: PEM electrolyzer.<br>Product after-sales and services: bipolar plate coating processing and design, diffusion layer coating processing.<br>

View MoreElectrolyzers.webp)

Polymer Electrolyte Membrane(PEM)Electrolyzers

High performance: The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard, and the gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Ion membrane electrolyzer

Acidized water electrolysis tank ( diaphragm)Effective chlorine concentration:10-120ppm<br> Working life>5000 h<br> Applications:<br> Animal husbandry disinfection<br> Disinfection of fruits and vegetables<br> Deodorization<br> Medical equipment disinfection<br>

View More

NaCl diaphragm electrolyzer

View More

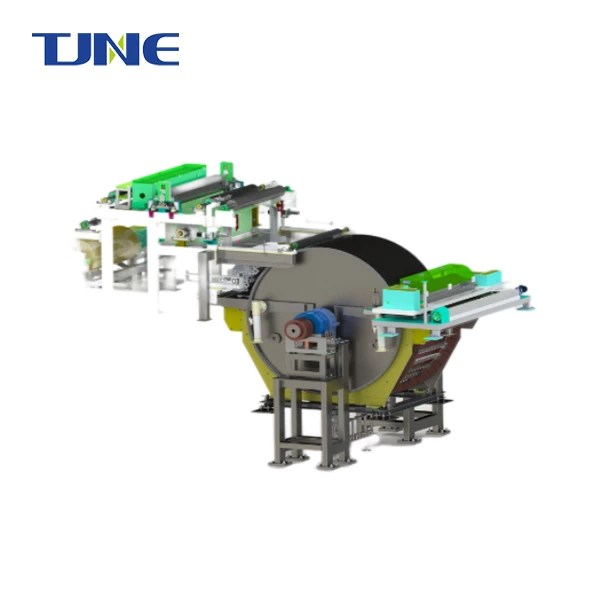

Electrolytic copper foil production machine

The world's first cathode roll with diameter of 3.6m, maximum width of 1.8m, and lithium copper foil exceeding 3.5μm.Loadable current strength: 60KAGrain size grade: ASTM ≥ 10 (domestic average 7~8)The foil machine is the core key equipment for the preparation of very thin electrolytic copper foil, and its components mainly include electrolyzer, anode plate, cathode roller support conductive device, online polishing device, stripping and winding device, etc.It adopts all-titanium electrolytic cell welding technology, which has a service life of up to 10 years; the continuously optimized copper foil tension control program can make the tension fluctuation range of the copper foil extremely small under the high-speed winding condition; and it adopts an online monitoring system to ensure the uniformity of the thickness of the copper foil and reduce the appearance defects.With a width of more than 1.8 meters and a running speed of more than 20m/min, the foil generator can produce very thin copper foils of 6 microns and below.

View More

MMO Tubular taitanium Anode

Product name: MMO Tubular taitanium Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, and anti-corrosion.<br>Titanium anode is widely used as a method in impressed current protection method;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

electrodeposited titanium electrode for copper

Product name: electrodeposited titanium electrode for copper<br>Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.<br>The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.<br>Product features: When electrolyzed in the electrolyte, it has strong oxidation ability, corrosion resistance, a small amount of lead dissolution, good conductivity, and the ability to pass large currents.<br>Product advantages: Compared with traditional lead anodes, the current efficiency can be increased by 2%, the lead dissolution rate is reduced by 99%, the service life is extended by 1 year, and the comprehensive use cost is reduced by 1%.<br>Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.<br>

View More