- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

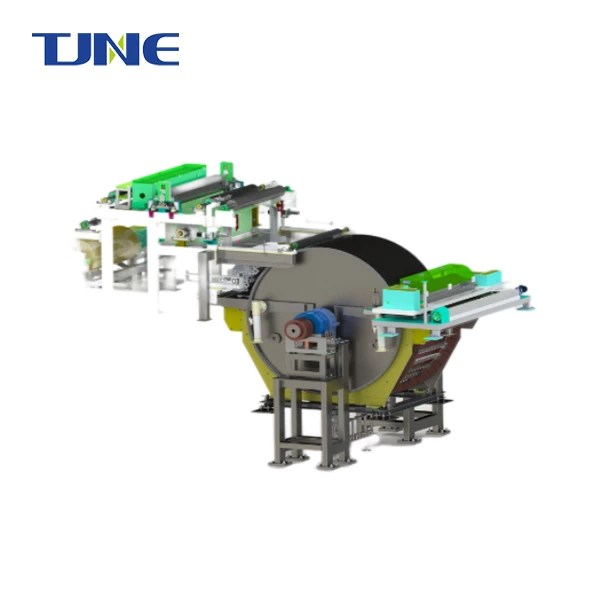

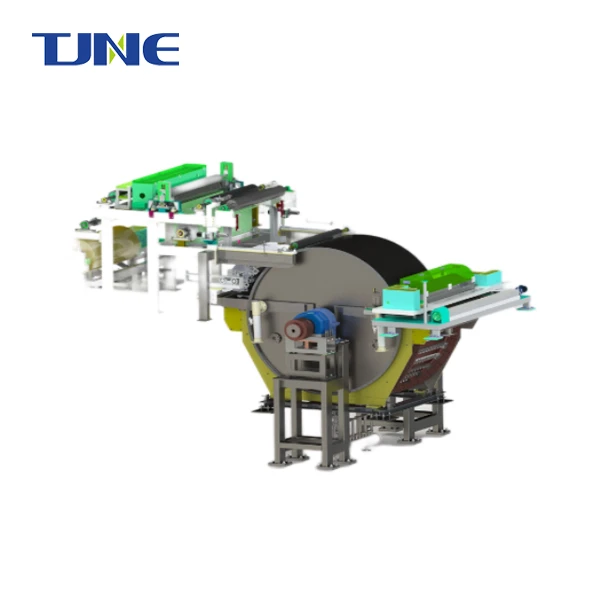

Electrolytic copper foil production machine

Electrolytic copper foil production machine

The Electrolytic Copper Foil Production Machine is a highly advanced machine that is designed to produce high-quality copper foils through the electrolysis process. This machine is widely used in various industries where copper foils are required, such as electronics, circuit boards, and telecommunications.

Product Introduction

The Electrolytic Copper Foil Production Machine is specifically designed to produce copper foils of various thicknesses and widths with precise specifications. It utilizes advanced electrolysis technology to ensure high purity and excellent conductivity of the copper foils. The machine is equipped with cutting-edge control systems and automation features to ensure efficient and reliable production.

Specifications

| Parameter | Specification |

|---|---|

| Product Type | Electrolytic Copper Foil Production Machine |

| Maximum Foil Width | 1200mm |

| Maximum Foil Thickness | 70μm |

| Production Speed | Up to 50 meters per minute |

| Power Consumption | 300 kW |

Economic Indicators

| Parameter | Value |

|---|---|

| Production Capacity | 5000 tons per year |

| Energy Efficiency | 90% |

| Operation Rate | 95% |

| Maintenance Cost | $10,000 per year |

System Components

The Electrolytic Copper Foil Production Machine consists of the following components:

-

Electrolysis Chamber

-

Electrolyte Circulation System

-

Copper Foil Cooling System

-

Control Panel

-

Automation System

Applications

The Electrolytic Copper Foil Production Machine is widely used in industries that require high-quality copper foils, including:

-

Electronics

-

Circuit Boards

-

Telecommunications

FAQ

1. What is the production capacity of the Electrolytic Copper Foil Production Machine?

The production capacity of the machine is 5000 tons per year.

2. What is the maximum foil width that can be produced?

The machine can produce copper foils with a maximum width of 1200mm.

3. Can the machine produce copper foils of different thicknesses?

Yes, the machine can produce copper foils with various thicknesses up to 70μm.

If you are looking for a reliable and professional Electrolytic Copper Foil Production Machine manufacturer and supplier, TJNE is the right choice. We offer advanced technology, comprehensive after-sales services, complete certification and testing reports, fast delivery, and secure packaging. Contact us at yangbo@tjanode.com to discuss your requirements.

YOU MAY LIKE

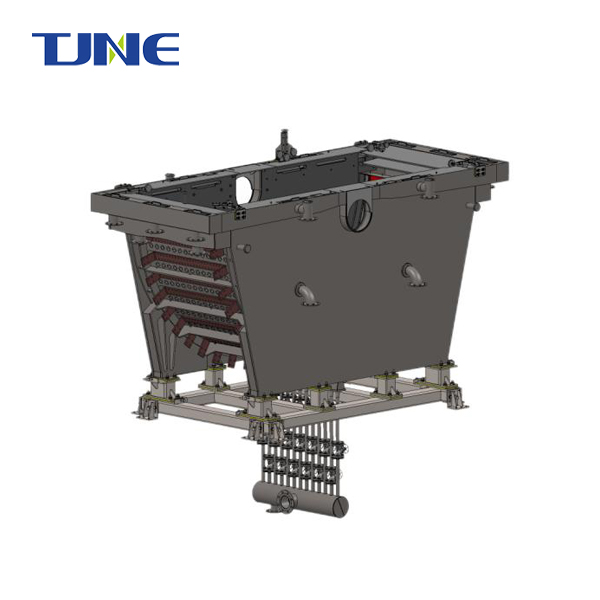

High efficiency Copper Dissolution Tank

Product name: High efficiency Copper Dissolution Tank<br>Product Overview: It is a device used to dissolve copper in the copper foil production process. Its main function is to dissolve copper ions in water to form an electrolyte.<br>Product advantages: efficient dissolution, stable operation, environmental protection and energy saving, easy maintenance, and high safety.<br>Technical advantages:<br>1. Maximize the copper-melting reaction speed and heat release without steam heating.<br>The negative pressure air formed in the tank is self-primed to reduce energy consumption.<br>2. The self-developed system improves the copper dissolving efficiency, and the copper dissolving efficiency can reach 260kg/h.<br>3. The guaranteed copper amount is ≤35 tons (the industry average is 80~90 tons), reducing system costs.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Copper Foil Anode

Product name: Copper Foil Anode<br>Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.<br>Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.<br>Technical advantages:<br>Long life: ≥40000kAh m-2 (or 8 months)<br>High uniformity: coating thickness deviation ±0.25μm<br>High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V<br>Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Titanium Anode Tank

Product name: Titanium Anode Tank<br>Product overview: It plays an important role in the production process of electrolytic copper foil. Its performance and quality directly affect the quality and output of copper foil.<br>Product advantages: good electrochemical performance, corrosion resistance, high-precision processing, reasonable and safe structure, etc.<br>Technical advantages:<br>a. Independently developed all-titanium welding technology<br>b. High precision: inner arc surface roughness ≤ Ra1.6<br>c. High rigidity: coaxially ≤±0.15mm; diagonal ≤±0.5mm, width ≤±0.1mm<br>d. High strength: no leakage within 5 years<br>e. Full specifications: Possessing the design and manufacturing capabilities for anode slots with a diameter of 500~3600mm<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Copper foil surface treatment machine

Product name: Copper foil surface treatment machine<br>Product Overview: A device specially used for surface treatment of electrolytic copper foil, aiming to improve the performance of copper foil.<br>Equipment composition: rewinding and unwinding device, detection system, power system, conductive system,<br>Spray washing and drying device, spray device, liquid roller transmission sealing device,<br>Safety/protection devices, electrical equipment, and control systems, electrolytic water washing tanks, etc.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

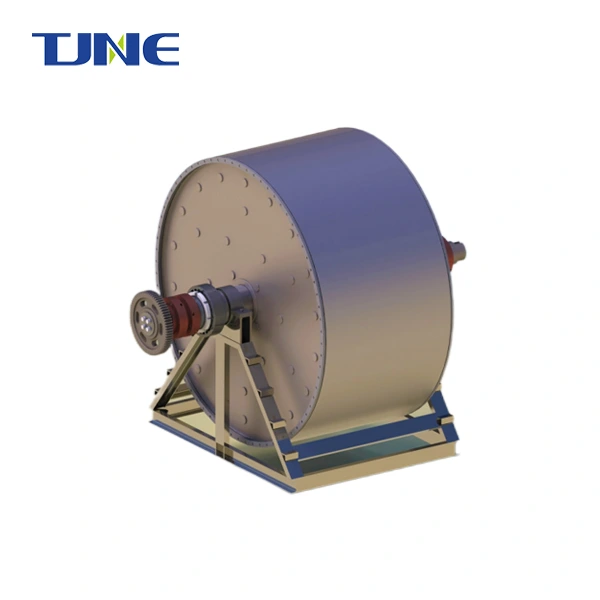

Titanium Cathode Drum

Maximum carrying current intensity: 50-75KA<br> Grain size grade: ASTM ≥ 10<br> Seamless anode roll diameter: 2016-3600mm, web width: 1020-1820mm<br> Lithium battery copper foil breakthrough 3.5μm<br> Anode roll surface Ra0.3μm, coaxiality: ±0.05mm, <br> straightness: ±0.05mm<br>

View More

Electrolytic copper foil production machine

Product name: Electrolytic copper foil production machine<br>Product overview: It is a composite equipment that integrates electrolysis, deposition, foil collection, surface treatment, and other functions. They are used to produce high-quality electrolytic copper foil.<br>Scope of application: printed circuit boards, lithium-ion batteries, electronic components, and other fields.<br>Performance parameters: Independently developed Mitsubishi/Lenz tension control system,<br>tension control accuracy ± 3N, production line speed fluctuation value: ± 0.02 m/min<br>Rewinding design achieves maximum diameter φ660-1000mm<br>Oscillation frequency 0~300 times/min (stepless speed regulation)<br>Visual current detection design, the polishing wheel polishing pressure can be directly read<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

MMO/Ti Flexible anode

The MMO/Ti Flexible Anode is a highly efficient and reliable product used in various industrial applications for cathodic protection. It is designed to protect metal structures and prevent corrosion by providing a low-resistance path for electric current.

View More

electrodeposited titanium electrode for nickel-cobalt

Product name: electrodeposited titanium electrode for nickel-cobalt<br>Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More