- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Polymer Electrolyte Membrane(PEM)Electrolyzers

Intelligent intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

Our Polymer Electrolyte Membrane( PEM) Electrolyzers are advanced electrochemical biases that use a polymer electrolyte membrane to produce hydrogen gas through the electrolysis of water. This slice-edge technology offers high effectiveness, continuity, and ease of operation.

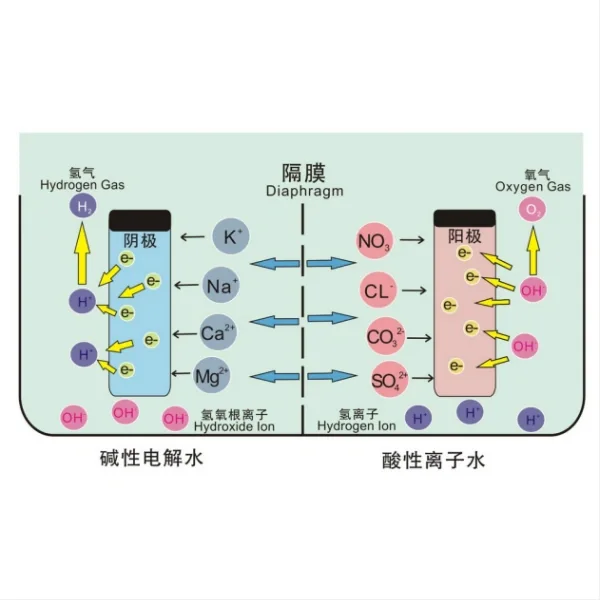

The PEM electrolyzer consists of a proton exchange membrane, two electrodes( anode and cathode), and an electrolyte result. When an electric current is applied, water motes are resolved into hydrogen ions( protons) and oxygen ions. The protons pass through the membrane to the cathode, while the oxygen ions resettle to the anode. At the cathode, the protons combine with electrons to form hydrogen gas, whereas at the anode, the oxygen ions combine to form oxygen gas.

High performance: The energy consumption of a single electrolyzer meets the national standard for first-class energy efficiency. The gas production of a single electrolyzer can reach up to 1500Nm3/h. Modular standard modules are integrated to adapt to large-scale solutions.

Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

High quality, standardized production, compact structure, high precision, and consistent product quality; eliminating the asbestos mesh design, which is environmentally friendly and reduces the environmental pollution of the alkali solution; the alkali tank frame has a one-to-one design

System Components and Specifications:

The Polymer electrolyte membrane electrolysis system consists of the following components:

| Component | Description |

|---|---|

| Proton Exchange Membrane | High-performance polymer membrane that selectively allows proton transport |

| Anode | Electrode where oxygen ions are formed |

| Cathode | Electrode where hydrogen gas is generated |

| Electrolyte Solution | Ion-conductive solution facilitating the ion transfer |

| Power Supply | Electric power source for driving the electrolysis process |

Performance Parameters

Our PEM electrolyzers offer the following performance parameters:

| Parameter | Value |

|---|---|

| Current Efficiency | ≥ 90% |

| Hydrogen Production Rate | Up to 5 Nm³/h |

| Operating Pressure | 0.1 - 3.0 MPa |

| Operating Temperature | 50 - 80°C |

Economic Indicators

The economic indicators of our PEM electrolyzers are illustrated in the table below:

| Indicator | Value |

|---|---|

| Initial Cost | Varies depending on system capacity |

| Operation and Maintenance Costs | Low |

| Life Cycle | 20,000 - 30,000 operating hours |

| ROI | Within 3 - 5 years |

Key Features and Advantages

-

High efficiency with a current efficiency of over 90%

-

Flexible hydrogen production rate, adaptable to various demands

-

Compact design and easy installation

-

Long life cycle and low operation and maintenance costs

-

Responsive after-sales service with certification and testing reports

-

Intensive design: The container design adapts to harsh outdoor environments, supports interface-type installation and high current density design, and the volume of electrolyzers is significantly smaller than conventional ones. Separation frame: many-to-one structure, improves equipment pipeline utilization and reduces investment costs;

-

Intelligent: It can realize intelligent operation and maintenance in the cloud and collect data to feed back equipment operation.

-

Safe and reliable: The equipment adopts intrinsically safe explosion-proof, and the system layer is designed to start and stop with one click and stop by mistake to maximize the safety of personnel.

Applications

Our PEM electrolyzers find applications in various industries, including:

-

Hydrogen fuel production

-

Renewable energy storage and grid balancing

-

Chemical and petrochemical processes

-

Electronic and semiconductor manufacturing

Product supply of photovoltaic modules, power station EPC, and hydrogen production equipment for the entire hydrogen production process, green electricity + green hydrogen, no carbon emissions in the entire process

Product after-sales and services: Provide timely and high-quality equipment debugging and installation equipment globally

FAQ:

1. What is the typical lifespan of a PEM electrolyzer?

The PEM electrolyzer typically has a lifespan of 20,000 to 30,000 operating hours.

2. Can the hydrogen production rate be adjusted?

Yes, the hydrogen production rate can be adjusted according to the requirements.

3. What are the main advantages of a PEM electrolyzer?

The main advantages of a PEM electrolyzer include high efficiency, compact design, and low operation and maintenance costs.

About TJNE:

TJNE is a leading manufacturer and supplier of Polymer Electrolyte Membrane (PEM) Electrolyzers. We specialize in providing high-quality products with comprehensive one-stop after-sales services. Our products have undergone rigorous certification and testing, and we ensure fast delivery with secure packaging. For inquiries or if you are interested in our PEM electrolyzers, please contact us at yangbo@tjanode.com

YOU MAY LIKE

DSA ANODE

Product name: DSA ANODE<br>Product Overview: An anode material used in electrochemical processes<br>The main component of the product: is Ti (titanium).<br>Product advantages: It has excellent corrosion resistance, low oxygen evolution overvoltage, and does not pollute cathode products.<br> It is expected to replace the traditional Pb anode and achieve energy saving.<br>Application areas: metal electrowinning, electroplating industry, microbial fuel cells, electrochemical energy storage systems, environmental protection fields, etc.<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

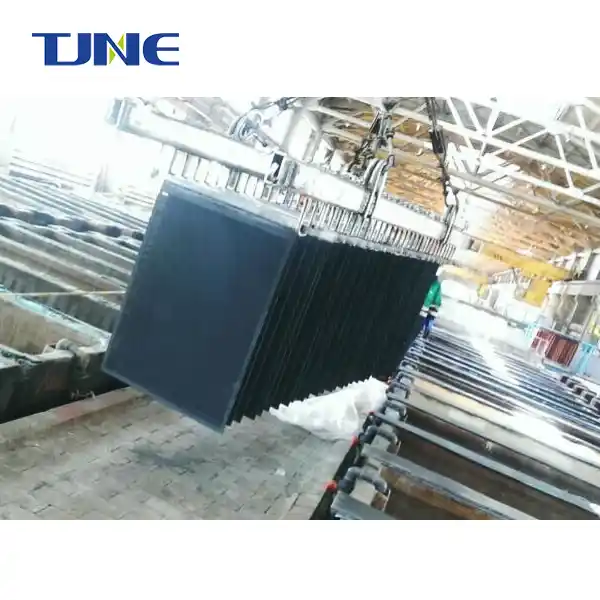

Electrode-diaphragm assembly for alkaline water electrolysis

Product name: Electrode-diaphragm assembly for alkaline water electrolysis<br>Product overview: flow channel design, processing, anti-corrosion coating processing, and gas diffusion layer coating processing of titanium bipolar plates in PEM electrolyzers.<br>Product features: No need to open a mold, the plate surface is highly flat, and the front and back plate type flow channels can achieve inconsistent graphics.<br>Highlights: high processing precision, low internal resistance of the coating, strong bonding force, and low surface contact resistance<br>Applicable scenarios: Bipolar plate processing design and diffusion layer design inside PEM electrolyzer.<br>Application conditions: PEM electrolyzer.<br>Product after-sales and services: bipolar plate coating processing and design, diffusion layer coating processing.<br>

View More

Nel Alkaline Electrolyser

High performance. The energy consumption of a single electrolyzer meets the national first-level energy efficiency standard. The gas production of a single electrolyzer can reach up to 1500Nm3/h.<br> Intelligent operation and maintenance; three-level control management: production management, DCS monitoring, PLC equipment management, chain alarm, automated control to improve operation and maintenance efficiency, safe and stable one-click start and stop, automatic chain shutdown due to misoperation: ensuring personal safety; long lifespan 200,000 hours

View More

Ion membrane electrolyzer

Acidized water electrolysis tank ( diaphragm)Effective chlorine concentration:10-120ppm<br> Working life>5000 h<br> Applications:<br> Animal husbandry disinfection<br> Disinfection of fruits and vegetables<br> Deodorization<br> Medical equipment disinfection<br>

View More

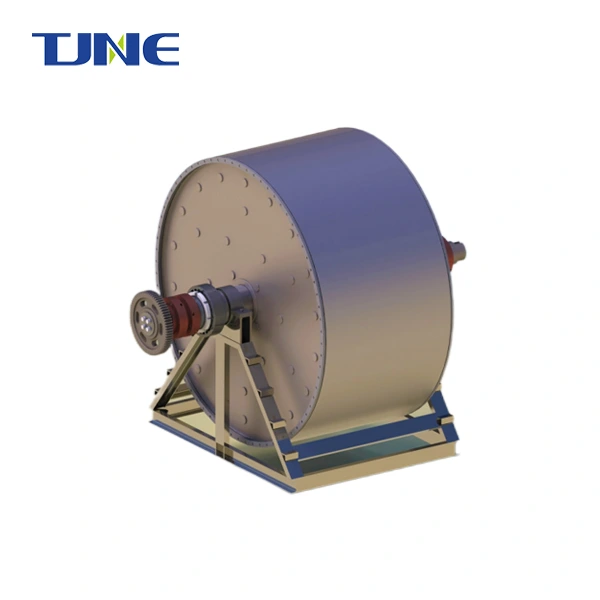

Titanium Cathode Drum

Maximum carrying current intensity: 50-75KA<br> Grain size grade: ASTM ≥ 10<br> Seamless anode roll diameter: 2016-3600mm, web width: 1020-1820mm<br> Lithium battery copper foil breakthrough 3.5μm<br> Anode roll surface Ra0.3μm, coaxiality: ±0.05mm, <br> straightness: ±0.05mm<br>

View More

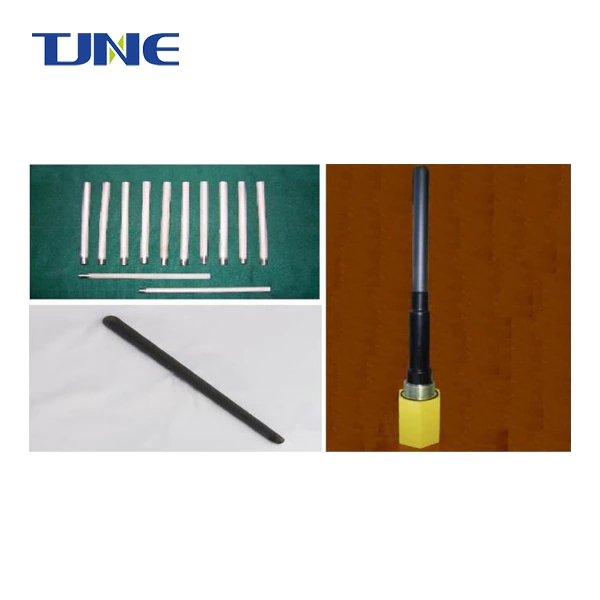

MMO Titanium Probe Anode

Product name: MMO Titanium Probe Anode<br>Product overview: The main body of the probe-type anode is an MMO rod-shaped anode, which adopts an advanced sealing system.<br>It consists of a water stop valve, an O-ring seal, and epoxy resin. After sealing, it can be used in high-pressure working conditions.<br>Advantages and features: Easy to install, can be installed directly through the wall from the outside;<br>Small size, lightweight, stable performance, and strong corrosion resistance;<br>The current density is very low, the power saving performance is excellent, and it has very stable performance;<br>Improve the coating formula and production process, the coating and the substrate are firmly bonded, and the service life is longer;<br>Applicable scenarios: Probe-type anodes are mainly used in impressed current cathodic protection systems on the inner surfaces of pipelines, water tanks, pressure vessels, etc.<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

Titanium electrode for Drinking water disinfection

View More

Ruthenium Iridium coated Titanium Anodes

Enhanced lifespan ≥ 280h<br> Chlorination potential ≤ 1.07 V<br> Reversible<br> R&D time:20+ years<br> Chlorination potential ≤ 1.07 V, reversible<br>

View MoreElectrolyzers.webp)