- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

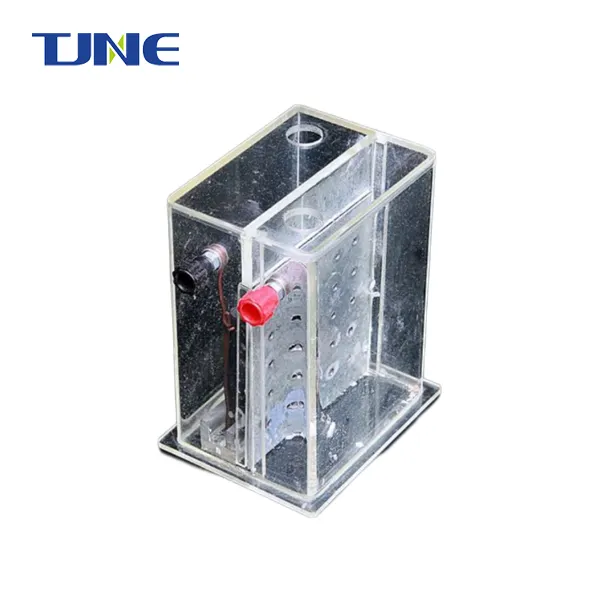

NaCl diaphragm electrolyzer

What Is NaCl Diaphragm Electrolyzer?

The sodium chloride diaphragm electrolyzer is a device used in the salt electrolysis process. It is mainly used to electrolyze sodium chloride solution into chlorine and hydrogen. A diaphragm electrolyzer has a porous separator (diaphragm) between the cathode and anode to prevent the two polar solutions from mixing but does not hinder the movement of ions and the passage of current. Diaphragm electrolyzers can be divided into horizontal and vertical types, and the vertical type can be divided into rectangular and circular types. The most widely used is the rectangular vertical electrolytic cell, which is simple to operate and has low cell voltage, but the concentration of the alkali solution produced is low.

In sodium chloride diaphragm electrolytic cells, precious metal-coated titanium anodes are usually used as anode materials, titanium is used as cathode materials and special materials are used to make diaphragms. It's extensively used in colorful diligence similar to chemical products, water treatment, and essence refining.

The electrolysis process of the diaphragm electrolyzer is as follows:

1. Anodic electrolysis: Chloride ions lose electrons at the anode and generate chlorine gas (Cl2).

2. Cathodic electrolysis: Hydrogen ions acquire electrons at the cathode to generate hydrogen gas (H2).

Diaphragm electrolyzers are widely used in the fields of chlorine, hydrogen and sodium hydroxide production. In addition, similar electrolytic cells are also used in the preparation of other chemicals, such as sodium chlorite, sodium hypochlorite, etc. In short, the sodium chloride diaphragm electrolyzer is an important chemical equipment used to realize the preparation and industrial production of chemicals.

The NaCl diaphragm electrolyzer consists of a diaphragm that separates the anode cube and the cathode cube. A direct current is applied to the electrodes submerged in the NaCl result. At the anode, chloride ions( Cl-) are oxidized to chlorine gas. At the cathode, water motes are reduced to form hydrogen gas and hydroxide ions( OH-). The diaphragm prevents the migration of chloride ions to the cathode, icing the separation of chlorine gas and sodium hydroxide result.

System Composition and Structure:

The NaCl diaphragm electrolyzer system is composed of the following components:

-

Anode compartment

-

Cathode compartment

-

Diaphragm

-

Electrodes

-

Power supply

The system is designed with high-quality materials to ensure durability and efficient electrolysis. The unique structure of the diaphragm allows for selective ion transport and efficient separation of the products. The electrodes are optimized for high performance and long lifespan.

Features and Advantages:

-

High chlorine production rate

-

Efficient separation of chlorine gas and sodium hydroxide solution

-

Optimized electrode design for long lifespan

-

Low energy consumption

-

Easy to operate and maintain

-

Wide range of application possibilities

Applications:

The NaCl diaphragm electrolyzer is widely used in the following industries:

-

Chemical production

-

Water treatment

-

Metal refining

-

Food processing

-

Pharmaceutical industry

FAQ:

-

Q: What is the lifespan of the electrodes?

-

A: The electrodes have a lifespan of approximately XX,000 hours of operation.

-

Q: What is the maintenance frequency?

-

A: Regular maintenance is recommended every XX months to ensure optimal performance.

-

Q: Can the electrolyzer be customized for specific requirements?

-

A: Yes, our company provides customization options to meet specific needs.

Contact Us:

If you are interested in choosing your own NaCl diaphragm electrolyzer, please feel free to contact us at yangbo@tjanode.com We are TJNE, a professional manufacturer and supplier of NaCl diaphragm electrolyzers. We specialize in providing high-quality products, comprehensive after-sales service, and timely delivery. Our products are certified and tested, ensuring the highest standards of quality.

YOU MAY LIKE

High concentration sodium hypochlorite generator (diaphragm electrolysis)

View More

Brine Electrolysis Sodium Hypochlorite Generator

Product Name: Brine Electrolysis Sodium Hypochlorite Generator<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine, and generates sodium hypochlorite through an oxidation-reduction reaction.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: used in the chemical industry, pharmaceutical, water treatment, and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Brine Electrolysis Equipment

Product name: Brine Electrolysis Equipment<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and small equipment footprint.<br>Application fields: used in chemical industry, pharmaceutical, water treatment and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Membrane electrolysis for NaCl

Product name: Membrane electrolysis for NaCl<br>Product overview: It is a device that uses membrane electrolysis technology to prepare sodium chloride.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: water treatment, hydrogen and oxygen production, environmental protection, and chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Modular Membrane Electrolyser

Product overview: It is a high-efficiency electrolysis equipment with a modular design.<br>Product advantages: modular design, high efficiency and energy saving, high stability, anti-pollution performance, automatic control, and easy maintenance.<br>Application areas: water treatment, hydrogen and oxygen production, environmental protection, chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide. <br>

View More

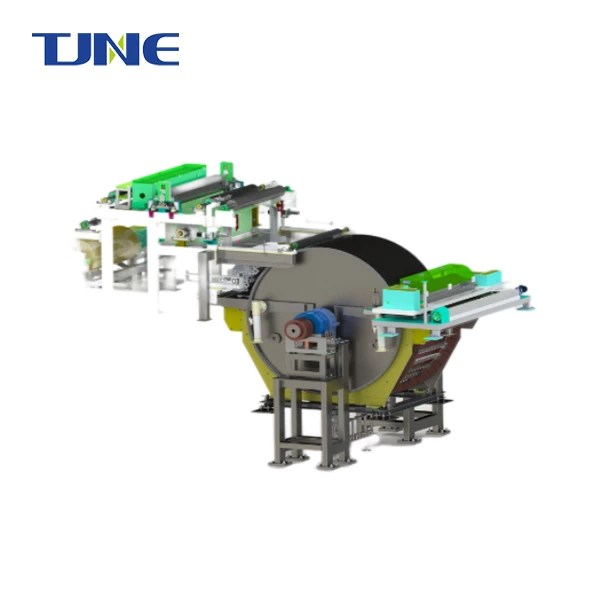

Electrolytic copper foil production machine

The world's first cathode roll with diameter of 3.6m, maximum width of 1.8m, and lithium copper foil exceeding 3.5μm.Loadable current strength: 60KAGrain size grade: ASTM ≥ 10 (domestic average 7~8)The foil machine is the core key equipment for the preparation of very thin electrolytic copper foil, and its components mainly include electrolyzer, anode plate, cathode roller support conductive device, online polishing device, stripping and winding device, etc.It adopts all-titanium electrolytic cell welding technology, which has a service life of up to 10 years; the continuously optimized copper foil tension control program can make the tension fluctuation range of the copper foil extremely small under the high-speed winding condition; and it adopts an online monitoring system to ensure the uniformity of the thickness of the copper foil and reduce the appearance defects.With a width of more than 1.8 meters and a running speed of more than 20m/min, the foil generator can produce very thin copper foils of 6 microns and below.

View More

MMO Titanium Mesh Anode

Product Name: Mmo Belt<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection and anti-corrosion.<br>Product features: The length of the electrode can be customized according to customer requirements.<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>The common specifications of MMO belts are as follows:<br>Titanium substrate composition: ASTM B 265GR1<br>Specifications: Width 6.35mm Thickness 0.635mm<br>Standard length: 152 meters/roll<br>

View More

electrodeposited titanium electrode for nickel-cobalt

Product name: electrodeposited titanium electrode for nickel-cobalt<br>Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More