- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PCB VCP DC Copper Plating DSA

Product Overview: Plating materials used in printed circuit board (PCB) manufacturing processes.

Product features: stable dimensions, firm coating, corrosion resistance, long service life;

effectively reduces tank voltage, a significant energy-saving effect;

ultra-low consumption can reduce production costs.

Advantages and highlights: long life (can be customized according to customer requirements);

low energy consumption, and high electrocatalytic activity.

Conditions of use: electrolyte CuSO4·5H20 H2SO4; temperature 20℃-45℃; current density 100-3000A/m2DC;

Applicable scenarios: VCP line/horizontal line copper plating, via/fill/pulse copper plating, soft/hard board plating, semiconductor substrate plating;

After-sales service: Providing timely and high-quality new anode manufacturing and old anode repainting services worldwide.

Product Details of PCB VCP DC Copper Plating DSA:

PCB VCP DC Copper Plating DSA is a highly advanced and efficient technology used for copper plating on printed circuit boards (PCBs). It provides excellent conductivity and corrosion resistance, making it ideal for electronic applications.

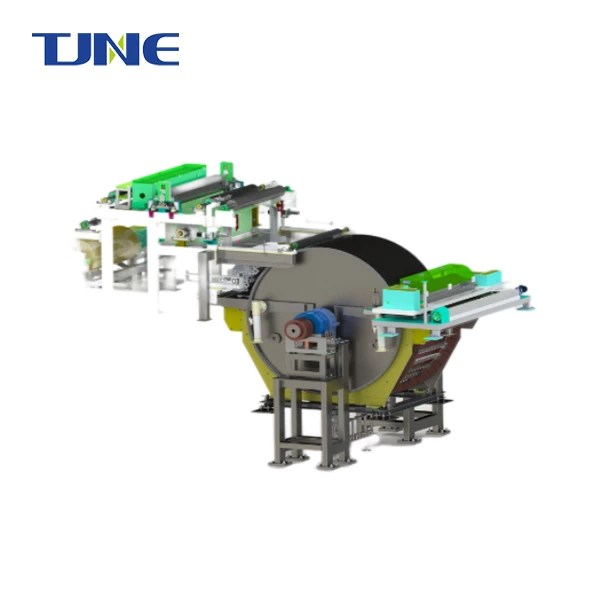

This system offers an efficient copper plating solution for printed circuit boards. It utilizes vertical continuous plating (VCP) technology and dimensionally stable anodes (DSA) to provide uniform copper deposition across PCB substrates. Key benefits of this system include high plating speed, excellent thickness uniformity, and consistency across various board sizes and shapes.

Operational features include PLC control of conveyor speed, adjustable plating currents, and monitoring of bath parameters like temperature, acid concentration, and organic additive levels. This enables optimized plating conditions for the desired copper thickness and hardness. The system can integrate with upstream processes like cleaning and downstream QA inspection.

Ideal for high-volume PCB manufacturing, the PCB VCP DC Copper Plating delivers high throughput with proven consistency and reliability. With the proper maintenance and part replacements, it provides extended up-time for maximum productivity.

Working Principle:

The PCB VCP DC Copper Plating DSA system comprises a series of interconnected components that work together to provide a consistent plating process. The chemical reactions involved ensure the deposition of a high-quality copper layer on the PCB surface. This technology utilizes a unique DSA (Dimensionally Stable Anodes) electrode, which significantly improves the plating uniformity and performance.

System Components:

The main components include:

Power supply unit

Anode baskets

Cathode rods

Dosing system

Control unit

Structure and Characteristics:

The system is designed with the following features:

Uniform and smooth copper plating surface

High conductivity and corrosion resistance

Enhanced PCB performance and durability

Efficient and reliable plating process

Performance Parameters:

| Parameter | Value |

|---|---|

| Copper plating thickness | 0.1-5 μm |

| Plating speed | 10-100 μm/min |

| Current efficiency | 95% |

Technical Specifications:

| Specification | Value |

|---|---|

| Voltage | 110-240V |

| Power consumption | 50-200W |

| Temperature range | 20-50°C |

Economic Indicators:

| Indicator | Value |

|---|---|

| Cost per unit | $1000 |

| Cost savings | Up to 50% |

Key Features and Advantages:

Uniform and high-quality copper plating

Improved conductivity and corrosion resistance

Enhanced PCB performance and durability

Efficient and reliable plating process

Applications:

The PCB VCP DC Copper Plating technology is widely used in the following industries:

Electronics

Telecommunications

Automotive

Medical devices

FAQ:

A: What is the plating thickness range achievable with this technology?

Q: The copper plating thickness range is typically between 1 to 50 microns, the specific range needs to be confirmed with the manufacturer.

A: Does the system require regular maintenance?

Q: Whether regular maintenance is required depends on usage and operating conditions, please consult the manufacturer for recommendations.

A: What is the average lifespan of the DSA electrodes?

Q: The average lifespan of DSA electrodes depends on the material, and usage environment, etc., please consult the manufacturer for accurate figures.

A: Is the technology compatible with various PCB sizes and shapes?

This type of product is generally compatible with mainstream PCB sizes and shapes. For specific compatibility, please check with the manufacturer according to your requirements.

For more information about our PCB VCP DC Copper Plating products, please contact us at yangbo@tjanode.com.

TJNE is a professional manufacturer and supplier of PCB VCP DC Copper Plating DSA. We offer high-quality products with strong technical expertise, complete certification and testing reports, fast delivery, and reliable packaging. Our one-stop after-sales service ensures customer satisfaction. Contact us today to discuss your requirements!

YOU MAY LIKE

Copper Foil Anode

Product name: Copper Foil Anode<br>Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.<br>Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.<br>Technical advantages:<br>Long life: ≥40000kAh m-2 (or 8 months)<br>High uniformity: coating thickness deviation ±0.25μm<br>High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V<br>Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Electrolytic copper foil production machine

The world's first cathode roll with diameter of 3.6m, maximum width of 1.8m, and lithium copper foil exceeding 3.5μm.Loadable current strength: 60KAGrain size grade: ASTM ≥ 10 (domestic average 7~8)The foil machine is the core key equipment for the preparation of very thin electrolytic copper foil, and its components mainly include electrolyzer, anode plate, cathode roller support conductive device, online polishing device, stripping and winding device, etc.It adopts all-titanium electrolytic cell welding technology, which has a service life of up to 10 years; the continuously optimized copper foil tension control program can make the tension fluctuation range of the copper foil extremely small under the high-speed winding condition; and it adopts an online monitoring system to ensure the uniformity of the thickness of the copper foil and reduce the appearance defects.With a width of more than 1.8 meters and a running speed of more than 20m/min, the foil generator can produce very thin copper foils of 6 microns and below.

View More

Electronic Titanium Anode Rod

Product Name: Electronic Titanium Anode Rod<br>Advantages and features: The characteristics of high-quality high-voltage anode foil are "two high and one thin", while ordinary high-voltage anode foil is economical and practical.<br>Applicable scenarios: aluminum foil molding<br>Specifications and performance:<br>a. Anode size: customized according to customer, plate shape<br>b. Anode coating: iridium tantalum coating<br>c.Anode life: greater than 18 months<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

MMO Tubular taitanium Anode

Product name: MMO Tubular taitanium Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, and anti-corrosion.<br>Titanium anode is widely used as a method in impressed current protection method;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

Titanium electrode for Drinking water disinfection

View More

electrodeposited titanium electrode for copper

Product name: electrodeposited titanium electrode for copper<br>Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.<br>The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.<br>Product features: When electrolyzed in the electrolyte, it has strong oxidation ability, corrosion resistance, a small amount of lead dissolution, good conductivity, and the ability to pass large currents.<br>Product advantages: Compared with traditional lead anodes, the current efficiency can be increased by 2%, the lead dissolution rate is reduced by 99%, the service life is extended by 1 year, and the comprehensive use cost is reduced by 1%.<br>Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.<br>

View MoreSemiconductor Plating DSA

Product Name: Semiconductor Plating DSA<br>Product overview: roll-to-roll plating, contact device plating, lead frame plating, electropolishing, selective spot plating, etc.<br>Product features: It can be selected and customized according to your own needs. The shape of the anode can be customized according to customer requirements.<br>Highlights: long life, low energy consumption, superior plating uniformity, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Semiconductor component plating: roll-to-roll plating, contact device plating, lead frame plating, electropolishing, selective spot plating, etc.<br>Application conditions: Electrolyte: acidic/cyanide system, gloss agent & other additives PH: 4-5; temperature 30℃-70℃;<br>Current density: 250-30000A/m2;<br>Coating type: mixed precious metal coating anode plating platinum anode, the platinum thickness can be lum-10um, or even thicker.<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

PCB Gold Plating DSA

Product name: PCB Gold Plating<br>Product Overview: Improve the conductivity, oxidation resistance, and wear resistance of circuit boards to meet their use needs in special occasions.<br>Product features: excellent performance, good electrocatalytic performance, antioxidant capacity, and stability.<br>Highlights: long life, low energy consumption, superior plating uniformity, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: circuit board gold plating<br>Application conditions: electrolyte acidic/cyanide system, gloss agent & other additives Au: 4-10g/L, CN: low concentration, PH: 4-5; temperature 40℃-60℃;<br>Current density: 0.1-1.0ASD; average 0.2ASD<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More