- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Brine Electrolysis Sodium Hypochlorite Generator

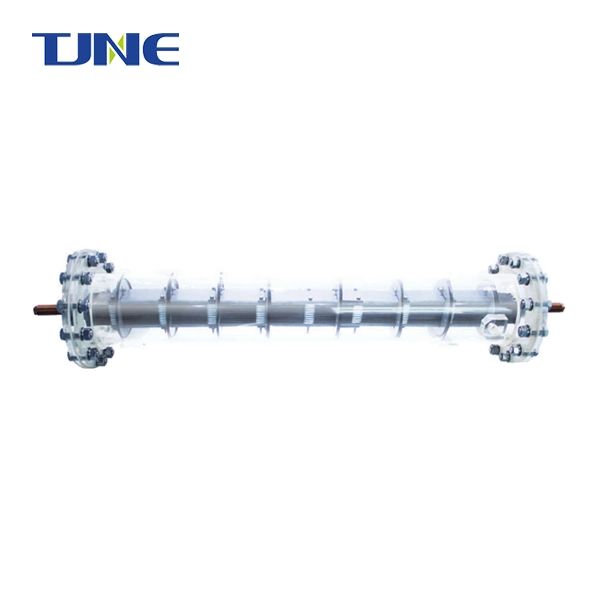

Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine, and generates sodium hypochlorite through an oxidation-reduction reaction.

Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.

Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.

Application fields: used in the chemical industry, pharmaceutical, water treatment, and other fields.

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

Brine Electrolysis Sodium Hypochlorite Generator Product Details:

The Brine Electrolysis Sodium Hypochlorite Generator is a state-of-the-art device designed to produce sodium hypochlorite( NaClO) using the process of electrolysis. It utilizes Neptune, a result of sodium chloride( NaCl), as the source material to induce a chlorine-grounded detergent. This creator is extensively used in colorful diligence for water treatment and sanitation purposes.

Working Principle:

Sodium Hypochlorite Generator From brine conforming to sodium chloride dissolved in water, is electrolyzed using an electrical current. The process involves the oxidation of chloride ions( Cl-) at the anode, forming chlorine gas( Cl2), which is also replied with water to produce hypochlorous acid( HOCl) and hypochlorite ions( OCl-). The attendant sodium hypochlorite result is collected and used as an effective detergent.

System Composition and Structure:

The Brine Electrolysis Sodium Hypochlorite Generator comprises several key components. These include:

-

Electrolysis Cell: Consisting of an anode and a cathode, where the electrolysis reaction takes place.

-

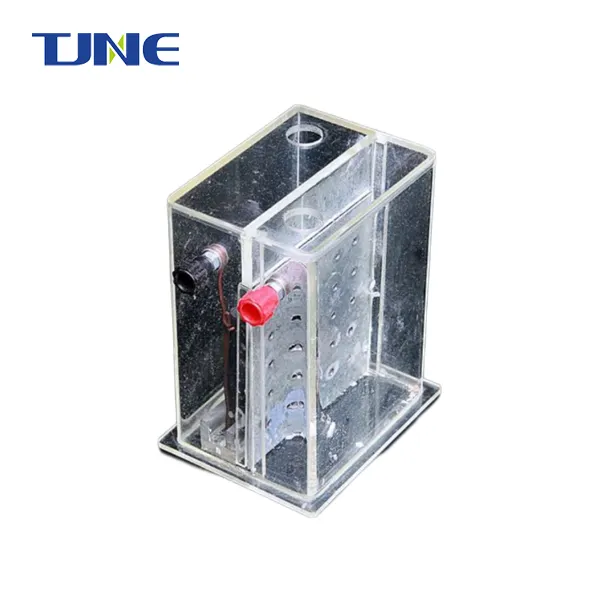

Salt Water Tank: Stores the brine solution for the electrolysis process.

-

Power Supply: Provides the necessary electrical current for electrolysis.

-

Reactant Tanks: Store water and sodium hydroxide (NaOH) as reactants for the chlorine generation process.

-

Reaction Chamber: This is where the chlorine gas is reacted with water to form the sodium hypochlorite solution.

-

Control System: Manages the operation and parameters of the generator.

Performance Parameters:

| Capacity | Operating Voltage | Chlorine Production Efficiency | Sodium Hypochlorite Concentration |

|---|---|---|---|

| 50-500 kg/day | DC 5-10 V | ≥90% | 0.8-1.0% |

Technical Parameters:

| Parameter | Value |

|---|---|

| Rated Power | 10-100 kW |

| Electrolysis Efficiency | ≥85% |

| Operating Temperature | 20-40°C |

| System Pressure | 0.2-0.5 MPa |

Economic Indicators:

| Indicator | Value |

|---|---|

| Power Consumption | 0.5-1.5 kWh/kg Cl2 |

| Chlorine Cost | ≤$2/kg Cl2 |

| Sodium Hypochlorite Cost | ≤$1/kg NaClO |

Features and Advantages:

-

High chlorine production efficiency, ensuring effective disinfection

-

Stable and adjustable sodium hypochlorite concentration for versatile applications

-

Advanced electrolysis technology for improved overall performance

-

Easy to operate and maintain

-

Compact and space-saving design

-

Environmentally friendly, with no harmful by-products

-

Robust construction for long service life

Applications:

The Sodium Hypochlorite Electrolyzer finds applications in a wide range of industries, including:

-

Water treatment and purification

-

Swimming pools and spa sanitation

-

Food and beverage processing

-

Aquaculture

-

Hospital and healthcare facilities

FAQ:

-

Q: What is the minimum and maximum capacity of the generator?

A: The generator can produce sodium hypochlorite in the range of 50-500 kg/day. -

Q: Is the generator easy to install?

A: Yes, it comes with a user-friendly installation guide and can be easily set up. -

Q: Can the generator be customized for specific requirements?

A: Yes, we offer customization options based on the specific needs of our customers.

For further inquiries or to purchase the Brine Electrolysis Sodium Hypochlorite Generator, please contact us at yangbo@tjanode.com. TJNE is a reputable manufacturer and supplier of these generators, offering strong technical expertise, comprehensive after-sales service, complete certification and testing reports, fast delivery, and secure packaging.

YOU MAY LIKE

chlorine generator electrolyzer

Chlorine precipitation anode life >5 years<br>,cathode life >20 years<br> Generation of effective chlorine concentration: ≥9000 ppm<br> Salt consumption: ≤2.8 kg/ kg·Cl,<br>DC power consumption: ≤3.5 kwh/kg·Cl

View More

Electro-catalytic oxidation equipment for ammonia nitrogen degradation

Product name: Electro-catalytic oxidation equipment for ammonia nitrogen degradation<br>Product Overview: It is an advanced oxidation equipment that uses electrocatalytic oxidation technology to treat ammonia nitrogen wastewater.<br>Components: electrolytic cell, plate, electrolyte, circulation pump and circulation tank, control system, pH control system, etc.<br>Product features: rapid response, simple operation, no secondary pollution, high efficiency and energy saving, strong adaptability, etc.<br>Applicable scenarios: Suitable for the treatment of various types of ammonia nitrogen wastewater.<br>Conditions of use: Appropriate electrocatalytic oxidation equipment needs to be selected based on wastewater characteristics and treatment requirements.<br>And adjust operating parameters to achieve optimal processing results.<br>Product after-sales service: Provide timely and high-quality equipment debugging and installation equipment globally.<br>

View More

High concentration sodium hypochlorite generator (diaphragm electrolysis)

View More

NaCl diaphragm electrolyzer

View More

Brine Electrolysis Equipment

Product name: Brine Electrolysis Equipment<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and small equipment footprint.<br>Application fields: used in chemical industry, pharmaceutical, water treatment and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Membrane electrolysis for NaCl

Product name: Membrane electrolysis for NaCl<br>Product overview: It is a device that uses membrane electrolysis technology to prepare sodium chloride.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: water treatment, hydrogen and oxygen production, environmental protection, and chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Modular Membrane Electrolyser

Product overview: It is a high-efficiency electrolysis equipment with a modular design.<br>Product advantages: modular design, high efficiency and energy saving, high stability, anti-pollution performance, automatic control, and easy maintenance.<br>Application areas: water treatment, hydrogen and oxygen production, environmental protection, chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide. <br>

View More

PCB Gold Plating DSA

Product name: PCB Gold Plating<br>Product Overview: Improve the conductivity, oxidation resistance, and wear resistance of circuit boards to meet their use needs in special occasions.<br>Product features: excellent performance, good electrocatalytic performance, antioxidant capacity, and stability.<br>Highlights: long life, low energy consumption, superior plating uniformity, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: circuit board gold plating<br>Application conditions: electrolyte acidic/cyanide system, gloss agent & other additives Au: 4-10g/L, CN: low concentration, PH: 4-5; temperature 40℃-60℃;<br>Current density: 0.1-1.0ASD; average 0.2ASD<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More