- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

MMO Ribbon Anode

Product Overview: Cathodic protection technology has been widely used in metallurgy, the chemical industry, environmental protection, and anti-corrosion.

Product features: Precious metal oxide composite-coated titanium electrodes can be selected and customized by customers according to their own needs. The length of the anode can be customized according to customer requirements.

Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.

Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.

Common specifications of mmo cathodic protection titanium anode strips are as follows:

Titanium substrate composition: ASTM B 265GR1

Specifications: Width 6.35mm Thickness 0.635mm

Standard length: 152 meters/roll

What is Mmo Ribbon Anode

The MMO Ribbon Anode is a highly efficient and durable anode used in various cathodic protection applications. It consists of a titanium substrate coated with a mixed metal oxide (MMO) catalyst. This anode is specifically designed to protect metallic structures from corrosion by supplying a protective current.

The MMO Ribbon Anode is constructed using high-quality titanium with an MMO catalyst coating. The anode utilizes the principle of electrochemical reactions to provide cathodic protection to structures submerged in electrolytes. The MMO catalyst ensures a highly active and stable anode performance, making it ideal for long-term corrosion prevention.

Working Principle

The Mixed metal oxide Anode operates based on the electrochemical reaction of the MMO catalyst when connected to a DC power source. The MMO catalyst facilitates the production of oxygen ions, which combine with water molecules to form hydroxyl ions. The hydroxyl ions provide an excess of electrons to the structure, effectively preventing corrosion.

System Components and Structure

It has the following components:

● Titanium substrate - Provides structural support and electrical conductivity.

● MMO catalyst coating - Facilitates electrochemical reactions and enhances anode performance.

The anode has a ribbon-like structure, allowing for easy installation on various surfaces. Its flexible nature ensures complete contact with the protected structure, maximizing the efficiency of the cathodic protection system.

Performance Parameters

| Parameter | Value |

|---|---|

| Current Output | Varies based on size and configuration |

| Service Life | Up to 20 years |

| Operating Temperature | -30°C to 80°C |

| Coating Thickness | Approximately 10-20 μm |

Technical Specifications

| Specification | Value |

|---|---|

| Substrate Material | Titanium Grade 1 or Grade 2 |

| Catalyst Composition | Iridium and/or Ruthenium Oxide |

| Dimensions (Width x Thickness) | Customizable |

| Weight | Varies based on size |

Economic Indicators

| Indicator | Value |

|---|---|

| Cost-effectiveness | High |

| Long-term Savings | Significant |

Key Features

● Highly efficient and durable.

● Provides long-term corrosion protection.

● Flexible and easy to install.

● Operates effectively in various environments.

● Low maintenance requirements.

Applications

Mixed metal oxide (MMO) ribbon anodes have become an important cathodic protection technology for corrosion prevention in major industries like oil and gas, marine transport, and municipal water infrastructure.

● Underground pipelines and tanks

A key application is providing corrosion protection for buried metallic pipelines and tanks transporting or containing corrosive substances. Mixed metal oxide ribbon anodes buried alongside or connected to the assets provide protective current flows that counteract external corrosion elements in the soil/water environment. This sustains the integrity of critical underground infrastructure like pipelines carrying wastewater, acids, or brine.

● Marine structures

In marine settings, attached to the submerged surfaces of ships, tankers, offshore rigs, and port structures generate protective currents that mitigate corrosion from seawater. The MMO materials resist seawater reactions while providing optimal current output to protect propellers, rudders, mooring devices, and other underwater assets vulnerable to electrolytic corrosion. This prevents damage, leaks, and failures.

● Oil and gas infrastructure

For above-ground storage tanks holding crude oil, acids, or other corrosive products, it is attached to tank exteriors to neutralize corrosion by supplying protective current flows. This maintains tank integrity and prevents leaks, explosions, and environmental contamination.

● Water treatment facilities

At water and wastewater treatment plants, it is utilized to protect submerged assets like clarifiers, screens, and sludge collection pipes made of metallic materials like carbon steel. Providing cathodic protection preserves equipment reliability and prevents corrosion contaminants from leaching into water supplies.

With capabilities for burial and submersion, it offers flexible form factors to provide reliable corrosion protection in places and geometries where conventional MMO plates or rods are impractical. As infrastructure ages globally, it will continue to see increased adoption for safeguarding critical assets against corrosion damage and failures.

FAQ

1. Can it be customized to specific dimensions?

Yes, it can be customized based on the requirements of the project.

2. What is the typical service life?

Can provide cathodic protection for up to 20 years.

3. Suitable for underwater applications?

Yes, they are designed to operate effectively in underwater environments.

Conclusion

TJNE is a professional manufacturer and supplier of Mmo Ribbon Anode. We specialize in providing high-quality, customizable anodes with excellent performance. Our one-stop service includes comprehensive technical support, certification testing, fast delivery, and secure packaging. If you are looking for your own Mixed metal oxide Ribbon Anode, please feel free to contact us at yangbo@tjanode.com

YOU MAY LIKE

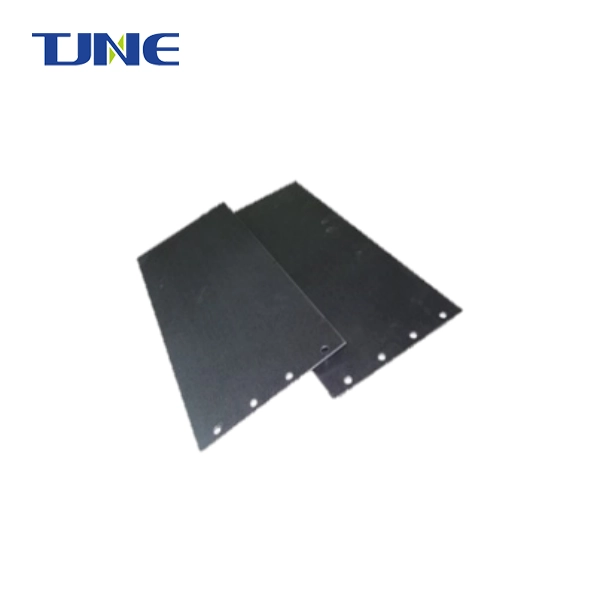

Mmo Anode Plate

Titanium composition:: ASTM B 265GR1<br> Specifications: Width 12.7mm Thickness 0.90mm<br> Standard length: 152 meters/roll<br> Advantage highlights: long life, low energy consumption, low comprehensive use cost, high cost performance

View More

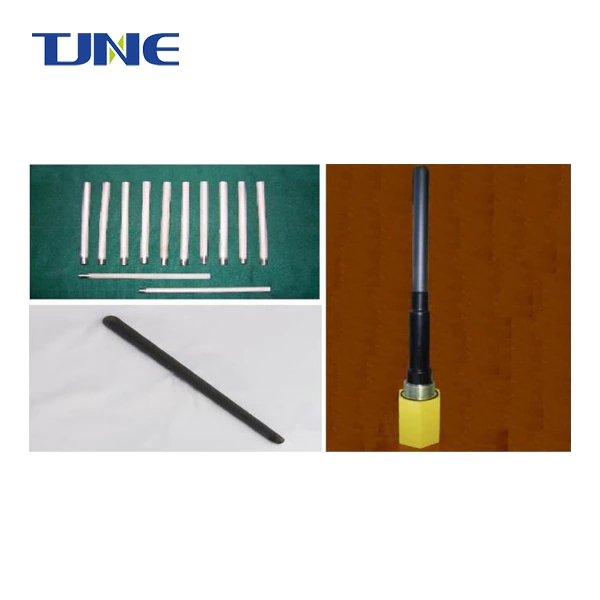

Electronic Titanium Anode Rod

Product Name: Electronic Titanium Anode Rod<br>Advantages and features: The characteristics of high-quality high-voltage anode foil are "two high and one thin", while ordinary high-voltage anode foil is economical and practical.<br>Applicable scenarios: aluminum foil molding<br>Specifications and performance:<br>a. Anode size: customized according to customer, plate shape<br>b. Anode coating: iridium tantalum coating<br>c.Anode life: greater than 18 months<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

MMO Titanium Probe Anode

Product name: MMO Titanium Probe Anode<br>Product overview: The main body of the probe-type anode is an MMO rod-shaped anode, which adopts an advanced sealing system.<br>It consists of a water stop valve, an O-ring seal, and epoxy resin. After sealing, it can be used in high-pressure working conditions.<br>Advantages and features: Easy to install, can be installed directly through the wall from the outside;<br>Small size, lightweight, stable performance, and strong corrosion resistance;<br>The current density is very low, the power saving performance is excellent, and it has very stable performance;<br>Improve the coating formula and production process, the coating and the substrate are firmly bonded, and the service life is longer;<br>Applicable scenarios: Probe-type anodes are mainly used in impressed current cathodic protection systems on the inner surfaces of pipelines, water tanks, pressure vessels, etc.<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

MMO/Ti Flexible anode

The MMO/Ti Flexible Anode is a highly efficient and reliable product used in various industrial applications for cathodic protection. It is designed to protect metal structures and prevent corrosion by providing a low-resistance path for electric current.

View More

MMO Canister Anode

View More

MMO Tubular taitanium Anode

Product name: MMO Tubular taitanium Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, and anti-corrosion.<br>Titanium anode is widely used as a method in impressed current protection method;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

MMO Titanium Mesh Anode

Product Name: Mmo Belt<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection and anti-corrosion.<br>Product features: The length of the electrode can be customized according to customer requirements.<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>The common specifications of MMO belts are as follows:<br>Titanium substrate composition: ASTM B 265GR1<br>Specifications: Width 6.35mm Thickness 0.635mm<br>Standard length: 152 meters/roll<br>

View More

Anode Plate

Product name: Anode Plate<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, the chemical industry, environmental protection, and anti-corrosion.<br>Product features: Precious metal oxide composite-coated titanium electrodes can be selected and customized by customers according to their own needs. The length of the anode can be customized according to customer requirements.<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Commonly used specifications and models of titanium metal conductive sheets are as follows:<br>Titanium composition:: ASTM B 265GR1<br>Specifications: Width 12.7mm Thickness 0.90mm<br>Standard length: 152 meters/roll<br>

View More