- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Removal of ammonia nitrogen Anode

Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.

Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.

Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.

As well as refractory organic wastewater and industrial wastewater.

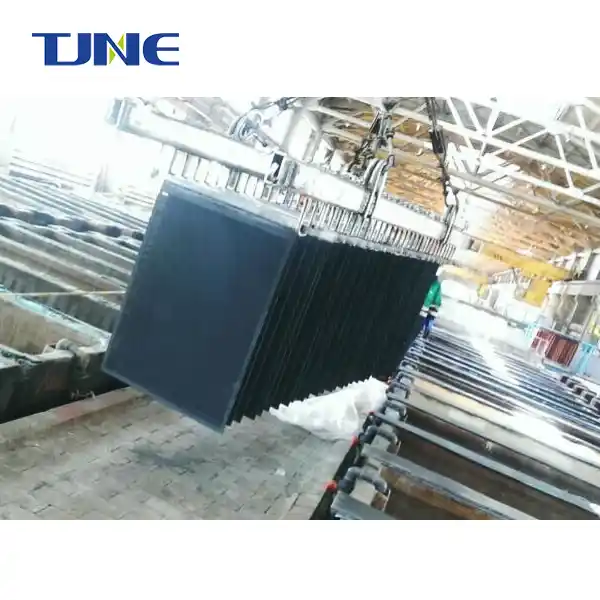

Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.

What is the Removal of Ammonia Nitrogen Anode?

The removal of ammonia nitrogen anode is a largely effective and dependable result for the junking of ammonia nitrogen from colorful wastewater sources. It's designed to offer superior performance and long-lasting continuity to ensure optimal results.

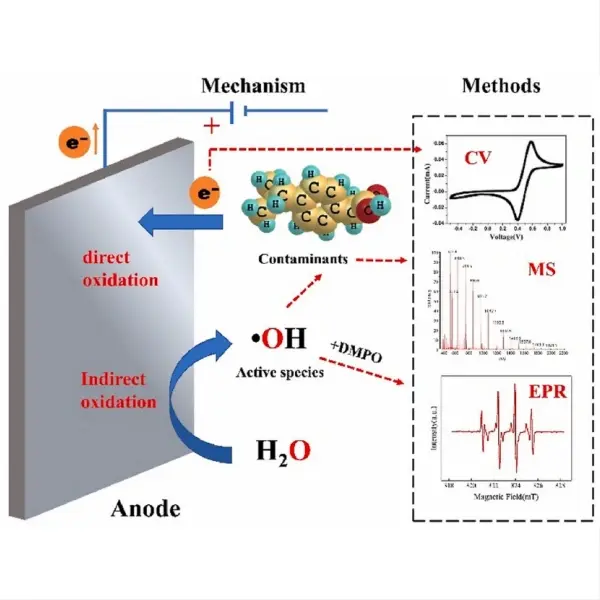

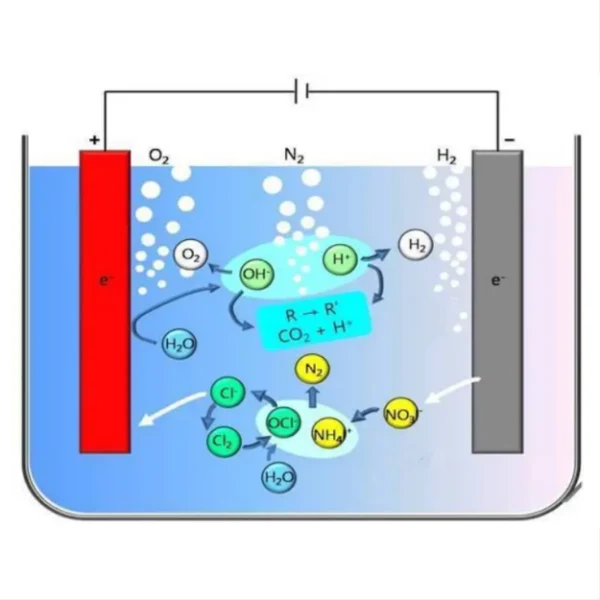

It utilizes advanced technology to effectively remove ammonia nitrogen from wastewater. It operates on the principle of chemical reactions, where the anode material catalyzes the decomposition of ammonia into harmless nitrogen gas.

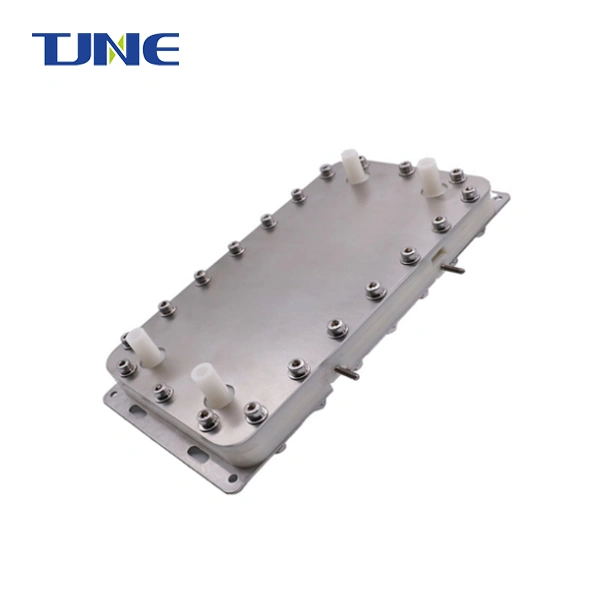

The system comprises a robust anode module, a power supply unit, and a control panel. The anode module consists of high-quality materials to withstand corrosive environments. It is designed to provide uniform distribution of electric current over the entire surface area, ensuring efficient ammonia nitrogen removal.

Key Features:

-

Highly efficient removal of ammonia nitrogen

Durable and corrosion-resistant construction

-

Uniform current distribution for optimal performance

-

Easy installation and maintenance

-

Compact design for space efficiency

Titanium anode is useful in removing ammonia nitrogen has the following advantages:

1. Efficient catalysis: Titanium anode has high activity and can produce more active oxidative species, such as hydroxyl radicals (·OH) during the electrolysis process, thereby improving wastewater treatment efficiency.

2. Corrosion resistance: Titanium material has excellent corrosion resistance. Even in harsh electrolysis environments, it can maintain stable electrocatalytic performance and extend the service life of the anode.

3. Good electrical conductivity: Titanium anode has high electrical conductivity, which can ensure the smooth progress of the electrolysis process.

4. Environmental performance: The active oxidative species produced by the titanium anode during the electrolysis process have strong oxidizing properties and can effectively degrade organic pollutants in wastewater and achieve advanced treatment of wastewater.

5. Wide range of applications: Titanium anodes are suitable for various electrolysis wastewater treatment processes, such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc., as well as refractory organic wastewater and industrial wastewater. The use of titanium anodes to remove ammonia nitrogen is a method that has the advantages of high efficiency, environmental protection, and energy saving.

Application Areas:

-

Wastewater Treatment Plants: removal of ammonia nitrogen anode can be utilized in wastewater treatment plants to facilitate the breakdown and removal of ammonia nitrogen from sewage and industrial effluents, ensuring that treated water meets environmental standards before being discharged into the environment or recycled.

-

Agricultural and Livestock Operations: In agricultural and livestock facilities, anodes can help in treating wastewater with high ammonia nitrogen levels, stemming from animal waste. This process ensures compliance with environmental regulations and mitigates the environmental impact.

-

Aquaculture and Fisheries: In the aquaculture industry, anodes may be used to reduce ammonia nitrogen levels in fish farm water, creating a healthier environment for aquatic life and promoting optimal fish growth.

-

Environmental Restoration: It can be applied in cases of environmental contamination, such as ammonia-nitrogen pollution in water bodies. Their use aids in restoring affected ecosystems to safe and environmentally compliant conditions.

-

Water Quality Improvement: In reservoirs or water bodies with elevated ammonia nitrogen levels, anodes can be employed to improve water quality and maintain a balanced aquatic ecosystem.

FA Q:

1. Is the anode module customizable?

Yes, the anode module can be tailored to meet specific requirements and dimensions.

2. How often does the anode need to be replaced?

The anode has a lifespan of 5-10 years, depending on operating conditions.

3. What is the lead time for delivery?

We strive to provide fast delivery within the agreed-upon timeframe.

4. Do you provide installation and maintenance support?

Yes, our team offers comprehensive installation and maintenance services to ensure optimal system performance.

If you are looking for a reliable and efficient Removal of Ammonia Nitrogen Anode, contact TJNE at yangbo@tjanode.com. We are a professional manufacturer and supplier with strong technical expertise, complete after-sales service, and certified testing reports. Our products are delivered quickly, securely packaged, and backed by our commitment to testing and quality assurance.

YOU MAY LIKE

Electrode-diaphragm assembly for alkaline water electrolysis

Product name: Electrode-diaphragm assembly for alkaline water electrolysis<br>Product overview: flow channel design, processing, anti-corrosion coating processing, and gas diffusion layer coating processing of titanium bipolar plates in PEM electrolyzers.<br>Product features: No need to open a mold, the plate surface is highly flat, and the front and back plate type flow channels can achieve inconsistent graphics.<br>Highlights: high processing precision, low internal resistance of the coating, strong bonding force, and low surface contact resistance<br>Applicable scenarios: Bipolar plate processing design and diffusion layer design inside PEM electrolyzer.<br>Application conditions: PEM electrolyzer.<br>Product after-sales and services: bipolar plate coating processing and design, diffusion layer coating processing.<br>

View More

Brine Electrolysis Equipment

Product name: Brine Electrolysis Equipment<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and small equipment footprint.<br>Application fields: used in chemical industry, pharmaceutical, water treatment and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Wastewater Disinfection and Oxidation Anode

Product name: Wastewater Disinfection and Oxidation Anode<br>Product Overview: Titanium anodes are improved through coating performance to improve electrolysis wastewater treatment effects.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Removal of COD Anode

Product name: Removal of COD Anode<br>Product Overview: OD is an indicator that measures the content of organic matter in water. The higher the value, the more serious the water pollution.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

MMO Tubular taitanium Anode

Product name: MMO Tubular taitanium Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, and anti-corrosion.<br>Titanium anode is widely used as a method in impressed current protection method;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

MMO Ribbon Anode

Product Name: MMO Ribbon Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, the chemical industry, environmental protection, and anti-corrosion.<br>Product features: Precious metal oxide composite-coated titanium electrodes can be selected and customized by customers according to their own needs. The length of the anode can be customized according to customer requirements.<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode strips are as follows:<br>Titanium substrate composition: ASTM B 265GR1<br>Specifications: Width 6.35mm Thickness 0.635mm<br>Standard length: 152 meters/roll<br>

View More

Ruthenium Iridium coated Titanium Anodes

Enhanced lifespan ≥ 280h<br> Chlorination potential ≤ 1.07 V<br> Reversible<br> R&D time:20+ years<br> Chlorination potential ≤ 1.07 V, reversible<br>

View More

Alkaline Water Electrolyser

Acid water+alkaline water output<br> Multi-stage diaphragm electrolysis<br> PH value of Acidic water:1.5-3;<br> PH value of Alkaline water:12-13<br> working life>5000h<br> By electrolyzing salt water, the anode produces acidic water and the cathode produces alkaline water

View More