- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electrochemical organic matter decomposition equipment

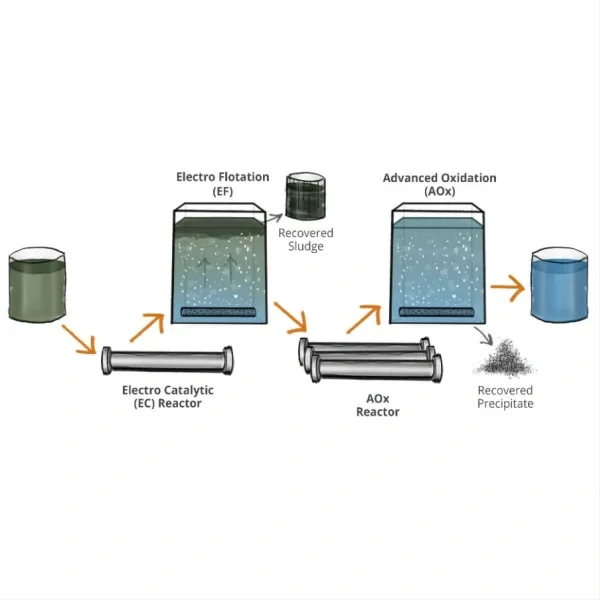

Product Overview: It is a device that uses electrochemical principles to decompose organic matter.

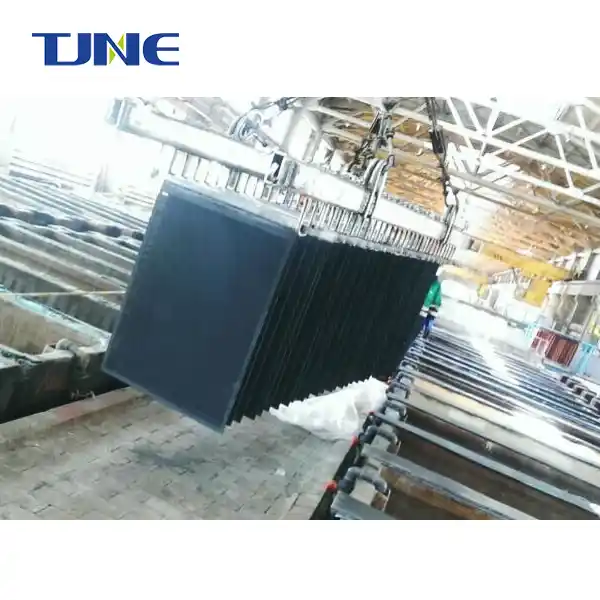

Components: electrolyzer, plates, electrolyte, DC power supply, control system, etc.

Product features: high decomposition efficiency, simple operation, no secondary pollution, strong adaptability, etc.

Applicable scenarios: Suitable for the treatment of all types of organic wastewater.

Application conditions: Appropriate electrochemical organic matter decomposition equipment needs to be selected based on wastewater characteristics and treatment requirements.

And adjust operating parameters to achieve optimal processing results.

Product after-sales and service: Provide timely and high-quality equipment debugging and installation equipment globally.

What is Electrochemical organic matter decomposition equipment?

The Electrochemical organic matter decomposition equipment, developed by TJNE, is a slice-edge technology designed for effective and eco-friendly organic matter corruption. This outfit is extensively used in colorful diligence similar to wastewater treatment, food processing, medicinal manufacturing, and more.

The system utilizes electrochemical processes to putrefy organic matter into simpler composites. It operates by applying a low-voltage electric current to the organic matter, driving oxidation-reduction responses that break down complex motes into lower factors. This process effectively removes dangerous adulterants and pollutants from the accouterments.

Structure and Features:

The system utilizes electrochemical processes to putrefy organic matter into simpler composites. It operates by applying a low-voltage electric current to the organic matter, driving oxidation-reduction responses that break down complex motes into lower factors. This process effectively removes dangerous adulterants and pollutants from the accouterments.

Features of the equipment include:

-

High decomposition efficiency

-

Low energy consumption

-

Easy operation and maintenance

-

Durable and corrosion-resistant materials

-

Advanced safety features

Performance and Technical Parameters

The electrochemical organic matter decomposition equipment is capable of decomposing a wide range of organic compounds with an efficiency of up to 95%. The following table presents the key performance and technical parameters:

| Parameter | Value |

|---|---|

| Decomposition efficiency | Up to 95% |

| Power consumption | Less than 2 kWh/kg |

| Operating voltage | 5-15 V |

| Electrode material | Titanium-based composite |

Economic Indicators

The electrochemical organic matter decomposition equipment offers significant economic benefits due to its low energy consumption and high efficiency. The table below highlights the key economic indicators:

| Indicator | Value |

|---|---|

| Return on investment (ROI) | Less than 1 year |

| Operating cost savings | More than 30% compared to conventional methods |

| Lifetime | 10+ years |

Applications:

The electrochemical organic matter decomposition equipment finds wide applications in various industries, including:

-

Wastewater treatment plants

-

Food and beverage production

-

Pharmaceutical manufacturing

-

Chemical processing

-

Textile industry

FAQ:

Q: Can this equipment handle high concentrations of organic matter?

A: Yes, the electrochemical organic matter decomposition equipment can effectively handle high concentrations of organic matter with its efficient decomposition process.

Q: How often does the electrolyte solution need to be replaced?

A: The electrolyte solution can be reused multiple times before replacement is required. The frequency of replacement depends on the specific operating conditions and organic matter load.

TJNE, as a specialized manufacturer and supplier of electrochemical organic matter decomposition equipment, offers products with high technical expertise and comprehensive after-sales service. Our equipment is backed by certification and complete testing reports. We ensure fast delivery with secure packaging and provide support for testing requirements. If you are in the process of selecting your electrochemical organic matter decomposition equipment, please feel free to contact us at yangbo@tjanode.com

YOU MAY LIKE

Copper Foil Anode

Product name: Copper Foil Anode<br>Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.<br>Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.<br>Technical advantages:<br>Long life: ≥40000kAh m-2 (or 8 months)<br>High uniformity: coating thickness deviation ±0.25μm<br>High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V<br>Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Electro-catalytic oxidation equipment for ammonia nitrogen degradation

Product name: Electro-catalytic oxidation equipment for ammonia nitrogen degradation<br>Product Overview: It is an advanced oxidation equipment that uses electrocatalytic oxidation technology to treat ammonia nitrogen wastewater.<br>Components: electrolytic cell, plate, electrolyte, circulation pump and circulation tank, control system, pH control system, etc.<br>Product features: rapid response, simple operation, no secondary pollution, high efficiency and energy saving, strong adaptability, etc.<br>Applicable scenarios: Suitable for the treatment of various types of ammonia nitrogen wastewater.<br>Conditions of use: Appropriate electrocatalytic oxidation equipment needs to be selected based on wastewater characteristics and treatment requirements.<br>And adjust operating parameters to achieve optimal processing results.<br>Product after-sales service: Provide timely and high-quality equipment debugging and installation equipment globally.<br>

View More

Brine Electrolysis Sodium Hypochlorite Generator

Product Name: Brine Electrolysis Sodium Hypochlorite Generator<br>Product Overview: It is a device that uses electrolysis technology to separate chloride ions and sodium ions in brine, and generates sodium hypochlorite through an oxidation-reduction reaction.<br>Product composition: electrolyzer, power supply, electrolyte circulation system, gas collection system, etc.<br>Product advantages: It has the advantages of high efficiency, environmental protection, energy saving, and a small equipment footprint.<br>Application fields: used in the chemical industry, pharmaceutical, water treatment, and other fields.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

MMO/Ti Flexible anode

The MMO/Ti Flexible Anode is a highly efficient and reliable product used in various industrial applications for cathodic protection. It is designed to protect metal structures and prevent corrosion by providing a low-resistance path for electric current.

View More

Titanium electrode for Drinking water disinfection

View More

Ruthenium Iridium coated Titanium Anodes

Enhanced lifespan ≥ 280h<br> Chlorination potential ≤ 1.07 V<br> Reversible<br> R&D time:20+ years<br> Chlorination potential ≤ 1.07 V, reversible<br>

View More

electrodeposited titanium electrode for copper

Product name: electrodeposited titanium electrode for copper<br>Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.<br>The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.<br>Product features: When electrolyzed in the electrolyte, it has strong oxidation ability, corrosion resistance, a small amount of lead dissolution, good conductivity, and the ability to pass large currents.<br>Product advantages: Compared with traditional lead anodes, the current efficiency can be increased by 2%, the lead dissolution rate is reduced by 99%, the service life is extended by 1 year, and the comprehensive use cost is reduced by 1%.<br>Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.<br>

View More

electrodeposited titanium electrode for nickel-cobalt

Product name: electrodeposited titanium electrode for nickel-cobalt<br>Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More