- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electro-catalytic oxidation equipment for ammonia nitrogen degradation

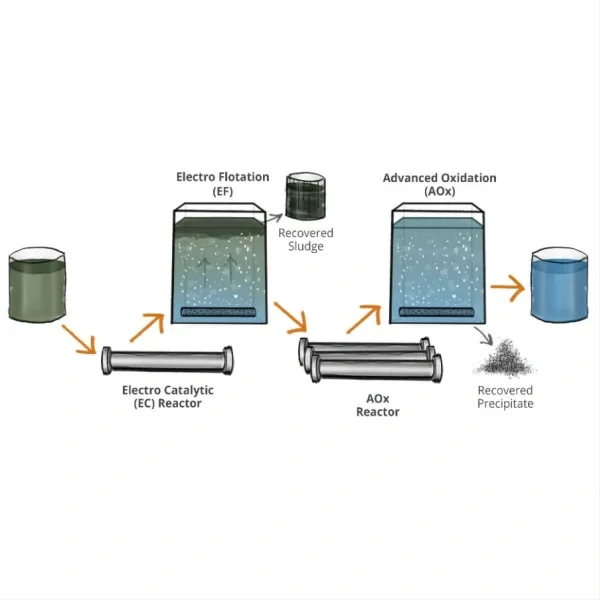

Product Overview: It is an advanced oxidation equipment that uses electrocatalytic oxidation technology to treat ammonia nitrogen wastewater.

Components: electrolytic cell, plate, electrolyte, circulation pump and circulation tank, control system, pH control system, etc.

Product features: rapid response, simple operation, no secondary pollution, high efficiency and energy saving, strong adaptability, etc.

Applicable scenarios: Suitable for the treatment of various types of ammonia nitrogen wastewater.

Conditions of use: Appropriate electrocatalytic oxidation equipment needs to be selected based on wastewater characteristics and treatment requirements.

And adjust operating parameters to achieve optimal processing results.

Product after-sales service: Provide timely and high-quality equipment debugging and installation equipment globally.

The Electro-catalytic oxidation equipment for ammonia nitrogen degradation is a state-of-the-art system designed to efficiently degrade ammonia nitrogen in various industrial wastewater streams. This equipment utilizes electro-catalytic oxidation technology to convert ammonia nitrogen into harmless byproducts such as nitrogen gas and water. With its advanced design and reliable performance, it offers an effective solution for the treatment of ammonia-nitrogen-rich wastewater.

The Electro-catalytic oxidation equipment involves passing ammonia nitrogen-rich wastewater through an electrochemical reactor where oxidation reactions occur at the anode catalyst. These oxidation reactions convert ammonia nitrogen into nitrogen gas, which gets released into the atmosphere, and water, which is further treated or discharged. The electro-catalytic oxidation equipment is capable of achieving high ammonia nitrogen degradation rates and offers excellent chemical performance. The closely controlled process parameters ensure the efficient removal of ammonia nitrogen from wastewater while minimizing energy consumption.

System Components and Features

The electro-catalytic oxidation equipment consists of the following components:

-

An electrochemical reactor with an anode catalyst

-

A power supply for providing the required electrical energy

-

A wastewater inlet for introducing the ammonia nitrogen-rich wastewater

-

A treated water outlet for removing the treated water

-

A nitrogen gas outlet for releasing the converted nitrogen gas

-

A control panel for monitoring and controlling the system parameters

The equipment is built with high-quality materials to ensure durability and long service life. It is designed to handle various flow rates and can be customized to meet specific project requirements. The system also features automatic operation, easy maintenance, and a user-friendly interface.

Performance and Technical Parameters

Some of the key performance and technical parameters of the Electro-catalytic oxidation equipment are as follows:

| Parameter | Value |

|---|---|

| Degradation Efficiency | ≥95% |

| Power Consumption | 2-5 kWh/m3 |

| Operating Temperature | 10-45°C |

| System Voltage | 220V / 380V |

| Control Mode | Automatic / Manual |

Economic Indicators

The electro-catalytic oxidation equipment offers excellent economic indicators, including low operation and maintenance costs, high energy efficiency, and reduced chemical consumption. The system helps industries meet environmental regulations and avoid penalties for non-compliance. It also helps in reducing the overall wastewater treatment cost by minimizing the use of expensive chemical reagents.

Key Features and Advantages

-

High degradation efficiency for ammonia nitrogen-rich wastewater

-

Energy-efficient operation

-

Easy to install and operate

-

Minimal maintenance requirements

-

Compact and modular design for space-saving installation

Applications

The electro-catalytic oxidation equipment is suitable for a wide range of industries, including:

-

Chemical manufacturing

-

Petrochemical refineries

-

Wastewater treatment plants

-

Fertilizer production

-

Pharmaceuticals

FAQ:

1. Is the electro-catalytic oxidation equipment customizable?

Yes, the equipment can be customized to meet specific project requirements.

2. Does the system require any chemical additives for ammonia nitrogen degradation?

No, the electro-catalytic oxidation process does not require any chemical additives.

3. What is the expected lifespan of the equipment?

The equipment is designed to have a long service life, typically exceeding 10 years with proper maintenance.

4. Can the equipment handle fluctuations in wastewater flow rates?

Yes, the equipment is designed to handle variations in wastewater flow rates and maintain consistent degradation efficiency.

TJNE is a professional manufacturer and supplier of electro-catalytic oxidation equipment for ammonia nitrogen degradation. We offer technical expertise, complete after-sales service, and comprehensive certification and testing reports. Our products are delivered quickly and securely packaged. If you are in the process of selecting your electro-catalytic oxidation equipment for ammonia nitrogen degradation, please feel free to contact us at yangbo@tjanode.com

YOU MAY LIKE

Copper Foil Anode

Product name: Copper Foil Anode<br>Product Overview: It is an electrolysis equipment used in the production process of copper foil. Its main function is to perform an electrolysis reaction on the titanium anode plate and reduce copper ions into the copper foil.<br>Product advantages: excellent electrochemical performance, corrosion resistance, precision processing, reasonable structure, safety, and reliability.<br>Technical advantages:<br>Long life: ≥40000kAh m-2 (or 8 months)<br>High uniformity: coating thickness deviation ±0.25μm<br>High conductivity: oxygen evolution potential ≤1.365V vs. Ag/AgCl, working condition cell voltage ≤4.6V<br>Low cost: Multi-layer composite electrode preparation technology reduces cell voltage by 15% and cost by 5%<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Electrochemical organic matter decomposition equipment

Product name: Electrochemical organic matter decomposition equipment<br>Product Overview: It is a device that uses electrochemical principles to decompose organic matter.<br>Components: electrolyzer, plates, electrolyte, DC power supply, control system, etc.<br>Product features: high decomposition efficiency, simple operation, no secondary pollution, strong adaptability, etc.<br>Applicable scenarios: Suitable for the treatment of all types of organic wastewater.<br>Application conditions: Appropriate electrochemical organic matter decomposition equipment needs to be selected based on wastewater characteristics and treatment requirements.<br>And adjust operating parameters to achieve optimal processing results.<br>Product after-sales and service: Provide timely and high-quality equipment debugging and installation equipment globally.<br>

View More

Modular Membrane Electrolyser

Product overview: It is a high-efficiency electrolysis equipment with a modular design.<br>Product advantages: modular design, high efficiency and energy saving, high stability, anti-pollution performance, automatic control, and easy maintenance.<br>Application areas: water treatment, hydrogen and oxygen production, environmental protection, chemical industry.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide. <br>

View More

Removal of ammonia nitrogen Anode

Product Overview: Ammonia nitrogen is a pollutant in water bodies and is harmful to the human body and the environment, so measures need to be taken to remove it.<br>Advantages and features: efficient catalysis, good corrosion resistance, good conductivity, environmental protection performance, etc.<br>Scope of application: Titanium anode is suitable for various electrolysis wastewater treatment processes.<br>Such as degrading toxic and harmful wastewater containing phenol, cyanide, chromium, etc.<br>As well as refractory organic wastewater and industrial wastewater.<br>Product after-sales service: We provide timely, high-quality new anode manufacturing and old anode recoating services worldwide.<br>

View More

Electronic Titanium Anode Rod

Product Name: Electronic Titanium Anode Rod<br>Advantages and features: The characteristics of high-quality high-voltage anode foil are "two high and one thin", while ordinary high-voltage anode foil is economical and practical.<br>Applicable scenarios: aluminum foil molding<br>Specifications and performance:<br>a. Anode size: customized according to customer, plate shape<br>b. Anode coating: iridium tantalum coating<br>c.Anode life: greater than 18 months<br>Product after-sales and service: We provide timely and high-quality new anode manufacturing and old anode recoating services globally.<br>

View More

MMO Wire Anode

Product name: MMO Wire Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, anti-corrosion, and other fields.<br>Titanium anodes are widely used as a method in impressed current protection methods;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments such as seawater, fresh water, soil media, etc.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

MMO Tubular taitanium Anode

Product name: MMO Tubular taitanium Anode<br>Product Overview: Cathodic protection technology has been widely used in metallurgy, chemical industry, environmental protection, and anti-corrosion.<br>Titanium anode is widely used as a method in impressed current protection method;<br>Advantage highlights: long life, low energy consumption, low comprehensive use cost, and high-cost performance.<br>Applicable scenarios: Suitable for cathodic protection projects in different environments, such as seawater, freshwater, and soil media.<br>Common specifications of mmo cathodic protection titanium anode tubes:<br>Titanium composition:: ASTM B 265 GR1<br>Specifications: diameter 25mm<br>Standard length: 1 meter/support 1.2 meters/support 1.5 meters/support<br>

View More

electrodeposited titanium electrode for nickel-cobalt

Product name: electrodeposited titanium electrode for nickel-cobalt<br>Product Overview: Precious metal-coated titanium anode is composed of mixed metal oxides (Ir, Ru, Ta, etc. oxides).<br>Product features: It can be used stably in chlorination and sulfuric acid systems, has a long service life, and can significantly reduce cell voltage during the electrowinning reaction.<br>Product advantages: After the surface active layer fails, it can be recoated, and the titanium matrix can be reused.<br>Application conditions: F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.<br>Application fields: Nickel chloride electrolysis, nickel sulfate electrolysis, cobalt chloride electrolysis, cobalt sulfate electrolysis, copper recovery from etching solution.<br>

View More