- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Are MMO/Ti Flexible Anodes the Future of Corrosion Protection?

2024-04-07 14:29:17

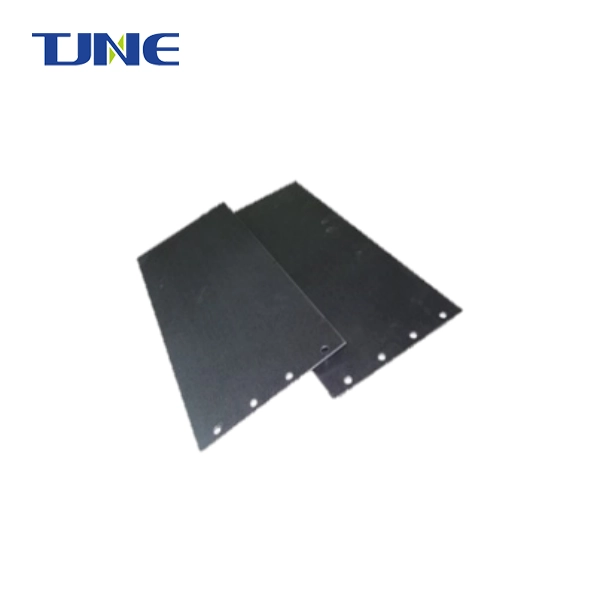

Enhanced Flexibility: MMO/Ti flexible anodes are highly flexible and can conform to irregular surfaces, complex geometries, and tight spaces with ease. This flexibility enables their application in areas where traditional rigid anodes cannot be used effectively, providing comprehensive corrosion protection for a wide range of structures and equipment.

Uniform Current Distribution: These anodes offer uniform current distribution across their entire surface area, ensuring consistent and effective corrosion protection. This uniformity helps prevent localized corrosion, which can be a significant concern in many applications.

High Efficiency: MMO/Ti flexible anodes provide efficient corrosion protection by delivering a high current density per unit area. This allows for the use of smaller anode sizes while still achieving adequate protection levels, resulting in cost savings and improved system performance.

Long Service Life: Like other MMO-based anodes, MMO/Ti flexible anodes have a long service life and are highly resistant to corrosion themselves. This ensures reliable and long-term corrosion protection for the protected structure or equipment, reducing maintenance requirements and associated costs.

Environmental Benefits: MMO/Ti flexible anodes are environmentally friendly, producing minimal byproducts during the corrosion protection process. They do not release harmful substances into the surrounding environment, making them a sustainable and eco-friendly choice for corrosion control applications.

Versatility: These anodes can be easily installed in a variety of environments, including marine, industrial, and infrastructure applications. Their versatility, combined with their flexibility and efficiency, makes them suitable for a wide range of corrosion protection challenges.

In the realm of corrosion protection, the advent of MMO/Ti Flexible Anodes marks a significant leap forward. These innovative anodes offer a versatile solution to the challenge of safeguarding complex structures against corrosion. In this article, we delve into the reasons behind the rising prominence of MMO/Ti Flexible Anodes, their unparalleled benefits, and their optimal utilization in various industrial applications.

What Makes MMO/Ti Flexible Anodes Ideal for Complex Structures?

The unique composition of MMO/Ti Flexible Anodes renders them exceptionally suited for protecting complex structures. Unlike traditional rigid anodes, these flexible counterparts can adapt seamlessly to irregular surfaces, intricate geometries, and hard-to-reach areas. This flexibility ensures comprehensive coverage, leaving no vulnerable spots susceptible to corrosion.

The key lies in the materials used. MMO, short for Mixed Metal Oxide, combined with titanium, forms the core of these anodes. This amalgamation imparts both durability and malleability to the anode, enabling it to conform to diverse structures with ease. Whether it's pipelines, storage tanks, or offshore platforms, MMO/Ti Flexible Anodes provide a tailored corrosion protection solution, effectively safeguarding assets against deterioration.

How Do MMO/Ti Flexible Anodes Enhance Longevity and Performance?

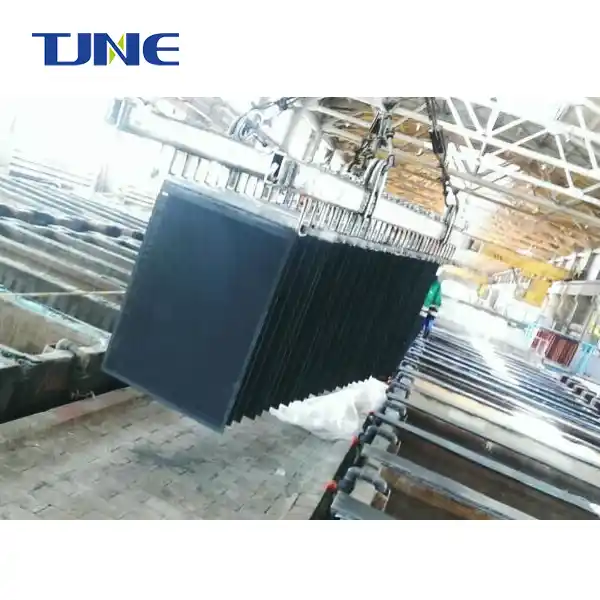

The longevity and performance of MMO/Ti Flexible Anodes stem from their inherent properties and innovative design. Firstly, the MMO coating ensures high efficiency in the electrochemical process, facilitating the generation of a protective current that counteracts corrosion. Secondly, the titanium substrate offers exceptional corrosion resistance, ensuring the anode's durability even in harsh environments.

Moreover, the flexibility of MMO/Ti Flexible Anodes not only simplifies installation but also minimizes the risk of mechanical damage. Traditional rigid anodes often face challenges in conforming to irregular surfaces, leading to ineffective protection and premature failure. Conversely, the adaptability of flexible anodes ensures uniform current distribution, maximizing corrosion inhibition and extending the service life of structures.

Where Can MMO/Ti Flexible Anodes Be Best Utilized in Industrial Applications?

The versatility of MMO/Ti Flexible Anodes makes them indispensable across a myriad of industrial applications. From marine infrastructure to buried pipelines, from reinforced concrete structures to underground storage tanks, these anodes offer a comprehensive corrosion protection solution. Their ability to conform to complex shapes and withstand harsh conditions makes them particularly suitable for:

· Offshore platforms and subsea pipelines

· Ship hulls and marine structures

· Underground storage tanks and pipelines

· Reinforced concrete structures in coastal or corrosive environments

By leveraging MMO/Ti Flexible Anodes, industries can mitigate the detrimental effects of corrosion, enhance asset longevity, and reduce maintenance costs effectively.

What Are the Key Maintenance and Installation Tips for MMO/Ti Flexible Anodes?

While MMO/Ti Flexible Anodes offer unparalleled corrosion protection, proper maintenance and installation are paramount to ensure optimal performance. Here are some key tips:

1. Surface Preparation: Ensure the surface is clean, dry, and free from contaminants before installing the anodes.

2. Proper Installation: Follow manufacturer guidelines for installation, including correct positioning and spacing of anodes.

3. Monitoring: Regularly monitor anode performance through inspection and testing to detect any anomalies.

4. Maintenance: Conduct periodic maintenance checks to ensure the integrity of the anode system and replace any deteriorated components promptly.

Adhering to these guidelines will maximize the effectiveness and longevity of MMO/Ti Flexible Anodes, ensuring continued corrosion protection for industrial assets.

Conclusion

In conclusion, MMO/Ti Flexible Anodes herald a new era in corrosion protection, offering unparalleled versatility, durability, and performance. Their ability to adapt to complex structures, coupled with long-term reliability, makes them the preferred choice across various industrial applications. By embracing these innovative anodes, industries can safeguard their assets effectively, mitigating the costly repercussions of corrosion-induced damage.

TJNE focuses on the research and development, design, production, and sales of high-end electrolytic complete sets of equipment and high-performance electrode materials. If you want to learn more about this kind of MMO/Ti Flexible anode, welcome to contact us: yangbo@tjanode.com.

References:

1. Li, Y., Qiu, J., Wu, X., & Li, Q. (2019). Research on the Application of MMO Flexible Anode in Cathodic Protection. Materials Science Forum, 945, 87-91.

2. Wang, C., & Cheng, Y. (2020). Development and Application of Flexible Anode. Applied Mechanics and Materials, 878, 87-93.

3. Nasir, A. M., Rahman, A. R., & Ahmad, A. L. (2017). A review on mixed metal oxides as anodes for cathodic protection of steel reinforced concrete structures. Construction and Building Materials, 141, 375-387.

4. Wang, Y., Zhou, Y., & Shi, W. (2021). Investigation of Coating Loading for MMO Flexible Anode in Cathodic Protection. Metals, 11(4), 651.

Related Industry Knowledge

- Which electrolyzer is best for hydrogen production?

- How Do Anodes Facilitate the Removal of Ammonia Nitrogen from Water?

- Revolutionizing Drinking Water Disinfection: The Role of Titanium Electrodes

- Electrochemical Essentials: The Comprehensive Guide to Anode Plates

- The Power of Splitting Water: An In-Depth Look at Alkaline Water Electrolyzers

- Crystal Clear Waters: Revolutionizing Pool Disinfection with Titanium Electrodes

- Purifying the Seas: The Role of Titanium Electrodes in Ballast Water Treatment

- How Does a Chlorine Generator Electrolyzer Enhance Pool Maintenance?

- How Does PCB VCP DC Copper Plating Work in Direct Current Systems?

- What Factors Should Be Considered When Selecting a Chlorine Generator Electrolyzer System?

Electrolyzers.webp)