- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

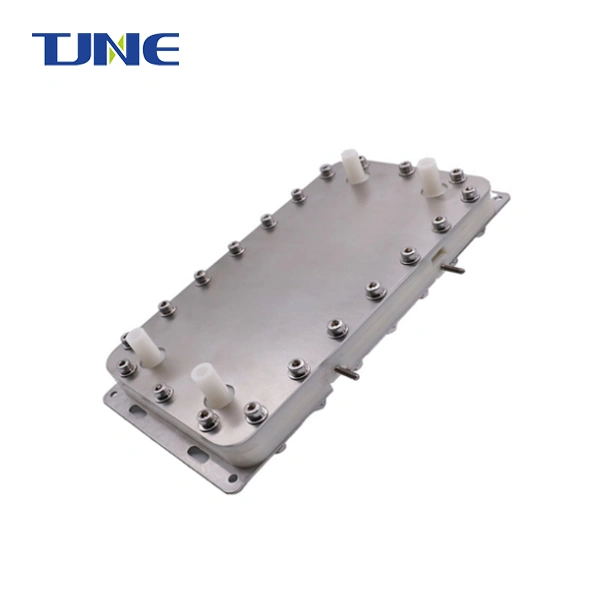

Iridium tantalum coated titanium anode

What is an Iridium tantalum-coated titanium anode?

Iridium-tantalum-coated titanium anode is a high-performance electrochemical anode material, mainly used in electrolysis, electroplating, electrocatalysis, and other fields. Its main component is a titanium (Ti) matrix, and the surface is coated with iridium (Ir) and tantalum (Ta) precious metal coatings. This anode material has many advantages, such as excellent corrosion resistance, high electrical conductivity, low oxygen evolution overpotential, etc., giving it excellent performance in various electrochemical processes.

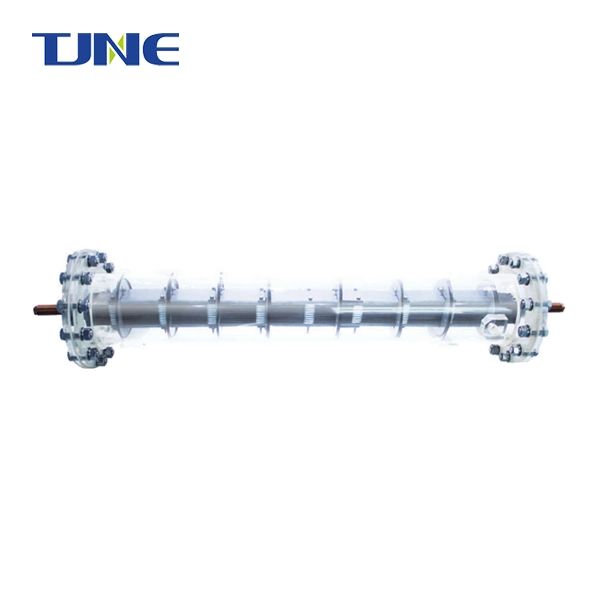

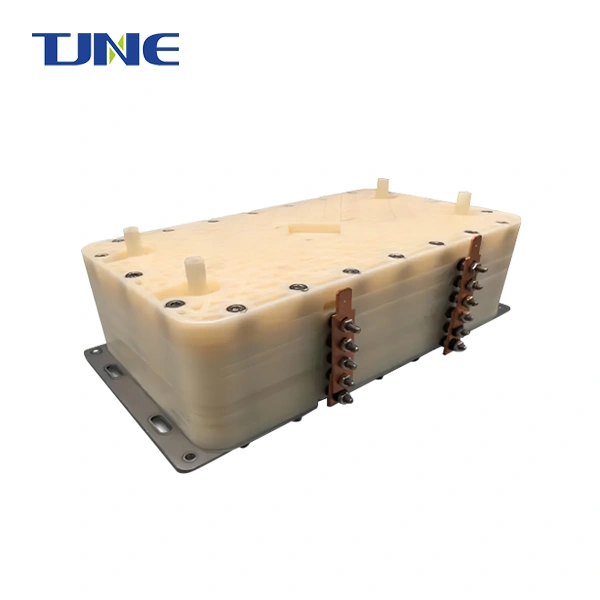

It consists of a titanium substrate coated with a layer of Iridium tantalum alloy. This alloy coating ensures high performance, durability, and electrical conductivity in corrosive environments. The anodes are commonly used in electrochemical processes where high stability and efficiency are required.

Working Principle and Chemical Properties

The Iridium tantalum coating provides excellent corrosion resistance, even in harsh chemical environments. It exhibits superior stability and durability during electrolysis, making it ideal for applications such as water treatment, electroplating, and electrochemical synthesis. The coating protects the titanium substrate from degradation and enhances the anode's overall lifespan.

System Composition and Detailed Structure

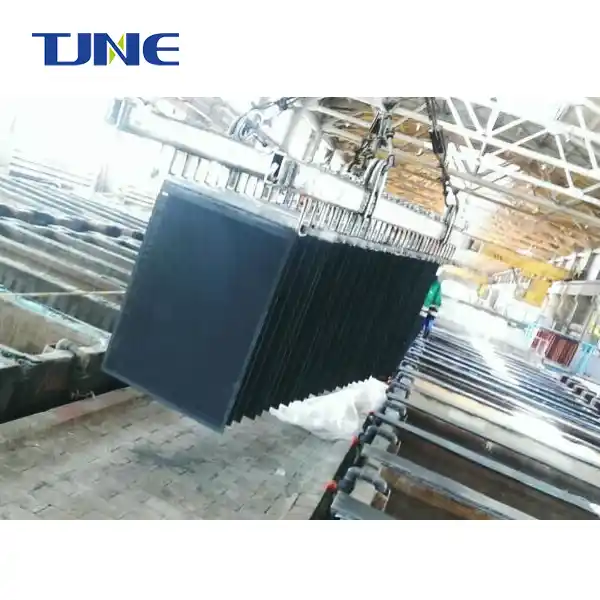

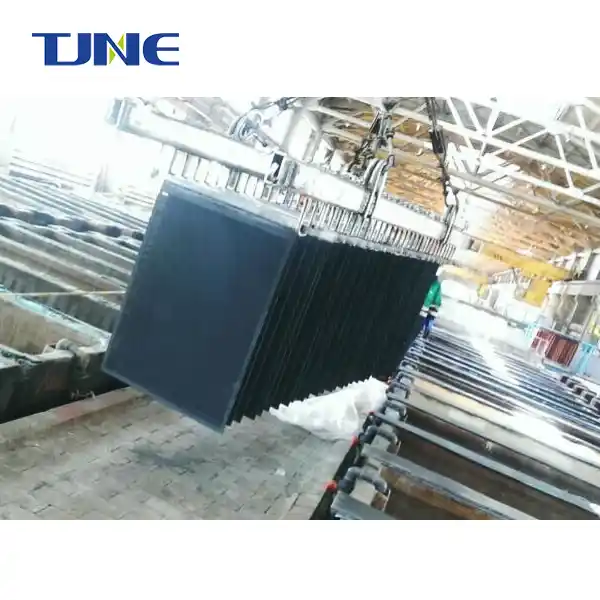

It's composed of a titanium substrate, which acts as the base material, and a subcaste of Iridium tantalum amalgamation coating. The coating is precisely applied to the substrate using a technical fashion to ensure uniformity and adhesion. The anodes are available in colorful shapes and sizes to meet different process conditions.

Performance Parameters

| Parameter | Value |

|---|---|

| Coating Thickness | 10-20 μm |

| Operating Voltage | 0.5-5 V |

| Current Density | ≤ 2000 A/m2 |

| Service Life | ≥ 5 years |

Characteristics and Advantages:

The main features and advantages of iridium-tantalum-coated titanium anodes are as follows:

(1). Anti-corrosion performance: Iridium-tantalum coated titanium anode has excellent anti-corrosion performance and can maintain stable operation in harsh electrochemical environments and extend its service life.

(2). Electrical conductivity: The iridium-tantalum-coated titanium anode has good electrical conductivity and low resistivity, which is beneficial to improving the efficiency of the electrolysis process.

(3). Low oxygen evolution overpotential: The iridium-tantalum coated titanium anode has a low oxygen evolution overpotential during the electrolysis process, which helps save energy, reduce consumption, and improve production efficiency.

(4). Good electrocatalytic performance: Iridium-tantalum coated titanium anode has excellent electrocatalytic performance and can be used to promote reactions such as oxygen evolution and chlorine evolution, and improve the efficiency of the electrolysis process.

(5). Stability: Iridium-tantalum coated titanium anode has good stability under extreme conditions such as high temperature and high pressure, and is suitable for various complex electrochemical processes.

(6). Environmental performance: Iridium-tantalum coated titanium anode releases almost no harmful substances during the electrochemical process, helping to reduce environmental pollution.

(7). Widely used: Iridium-tantalum coated titanium anodes can be used in many electrochemical fields such as metal electrowinning, electroplating, fuel cells, and cathode electrophoresis.

In summary, iridium-tantalum coated titanium anode is an electrochemical anode material with excellent performance and broad application prospects. With the continuous development of science and technology, the application of iridium-tantalum-coated titanium anodes in various fields will continue to expand, bringing more innovations and breakthroughs to electrochemical processes.

|

|

|

Technical Parameters

| Parameter | Value |

|---|---|

| Titanium Substrate | Grade 1 or Grade 2 |

| Iridium Tantalum Coating | 90% Iridium + 10% Tantalum |

| Substrate Size | Customizable |

Economic Indicators

Our Iridium tantalum-coated titanium anode offers excellent cost efficiency in various applications. The extended service life and high performance reduce the need for frequent replacements, resulting in cost savings in the long run.

Application:

1. Water treatment

Iridium Tantalum (IrTa) coated titanium anodes represent an advanced electrode material that finds diverse uses across several industrial electrochemical processes. A major application is in water treatment, where IrTa-coated titanium acts as a dimensionally stable anode for processes like electro-oxidation and electrochemical disinfection of municipal wastewater and industrial effluents. The IrTa coating provides excellent corrosion resistance in harsh environments containing chlorides and other contaminants, allowing sustainable operation. It also exhibits outstanding electrocatalytic activity for oxygen evolution from water, generating reactive oxidants to degrade organic pollutants and inactivate disease-causing pathogens. Compared to conventional DSA materials, IrTa demonstrates a longer lifespan and lower energy consumption.

2. Chlor-alkali industry

Additionally, the chlor-alkali industry utilizes IrTa-coated titanium extensively in the electrolysis of brine for chlorine and caustic soda production. The electrodes withstand the highly corrosive brine environment while also electrolyzing salt efficiently over prolonged production runs. The dimensional stability of the titanium substrate coupled with the electrocatalytic activity of the IrTa coating enables consistent and reliable performance. Replacing older graphite anodes with IrTa-coated titanium has allowed significant efficiency gains in chlor-alkali plants.

3. Electroplating

For metal electroplating processes, like chromium plating, IrTa-coated titanium provides inert, non-consumable anodes necessary for uniform metal deposition onto cathodic workpieces. The inert anodes eliminate metal contamination from anode dissolution observed with consumable metal anodes. IrTa’s dimensional stability also ensures precise workpiece plating. Other electroplating applications include nickel, copper, tin, zinc, and precious metals.

4. Electrochemical synthesis

In the electrochemical synthesis of organic compounds and specialty chemicals, IrTa-coated titanium serves as a reliable high-performance anode. It withstands aggressive organic intermediates/reagents while facilitating selective electrochemical oxidation reactions at its surface. Key examples include electrochemical fluorination and electrophilic aromatic substitution, producing useful fluorinated and chlorinated aromatic compounds.

5. Cathodic protection

Additionally, IrTa-coated titanium is used as an inert auxiliary anode material in cathodic protection systems for corrosion prevention in pipelines, storage tanks, marine structures, and other metal infrastructure. By generating protective current flows, the anodes mitigate external corrosion.

To summarize, Iridium tantalum-coated titanium anodes provide critical functionality across diverse electrochemical processes where corrosion resistance, electrocatalytic performance, and dimensional stability are paramount. Their exemplary attributes enable broad use in vital industries like water treatment, chlor-alkali production, metal plating, organic chemical synthesis, and cathodic protection. Continued improvements in IrTa coating technology and alloy composition will likely expand the application space of this versatile class of dimensionally stable anodes.

FAQ

Q: How long does the Iridium tantalum coating last?

A: Our anodes have a service life of at least 5 years under normal operating conditions.

Q: Can the anodes be customized to specific sizes?

A: Yes, we offer customization services to meet your unique requirements.

Q: What is the recommended current density for these anodes?

A: The recommended maximum current density is 2000 A/m^2.

Q: Are the anodes suitable for highly corrosive environments?

A: Yes, the Iridium tantalum coating provides excellent corrosion resistance, making the anodes suitable for use in aggressive environments.

Conclusion

Choose TJNE as your reliable supplier of Iridium tantalum-coated titanium anode. Our strong technical expertise, comprehensive one-stop service, and high-quality products ensure your satisfaction. Contact us today at yangbo@tjanode.com to discuss your specific requirements.

YOU MAY LIKE

Ballast water titanium electrode

1.Chlorine precipitation anode life >5 years,cathode life >20 years<br>2.Generation of effective chlorine concentration: ≥9000 ppm<br> 3.Salt consumption: ≤2.8 kg/ kg·Cl,DC power consumption: ≤3.5 kwh/kg·Cl

View More

chlorine generator electrolyzer

Chlorine precipitation anode life >5 years<br>,cathode life >20 years<br> Generation of effective chlorine concentration: ≥9000 ppm<br> Salt consumption: ≤2.8 kg/ kg·Cl,<br>DC power consumption: ≤3.5 kwh/kg·Cl

View More

acidic electrolytic water

Efficient electrolysis, integrated design, effective chlorine electrolysis 10-200ppm<br> Hypochloric acid water with a pH value of 3-7, Working life>5000 h<br> Applications:<br> Animal husbandry disinfection<br> Disinfection of fruits and vegetables<br> Deodorization<br> Medical equipment disinfection<br>

View More

Titanium electrode for swimming pool disinfection

CChlorine precipitation anode life >5 years,cathode life >20 years<br> Generation of effective chlorine concentration: ≥9000 ppm<br> Salt consumption: ≤2.8 kg/ kg·Cl,DC power consumption: ≤3.5 kwh/kg·Cl<br>

View More

Titanium electrode for Drinking water disinfection

View More

Ruthenium Iridium coated Titanium Anodes

Enhanced lifespan ≥ 280h<br> Chlorination potential ≤ 1.07 V<br> Reversible<br> R&D time:20+ years<br> Chlorination potential ≤ 1.07 V, reversible<br>

View More

Alkaline Water Electrolyser

Acid water+alkaline water output<br> Multi-stage diaphragm electrolysis<br> PH value of Acidic water:1.5-3;<br> PH value of Alkaline water:12-13<br> working life>5000h<br> By electrolyzing salt water, the anode produces acidic water and the cathode produces alkaline water

View More

Titanium electrode for swimming pool Disinfection

1.CChlorine precipitation anode life >5 years, cathode life >20 years<br> 2. Generation of effective chlorine concentration: ≥9000 ppm<br> 3.Salt consumption: ≤2.8 kg/ kg·Cl,DC power consumption: ≤3.5 kwh/kg·Cl

View More