- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

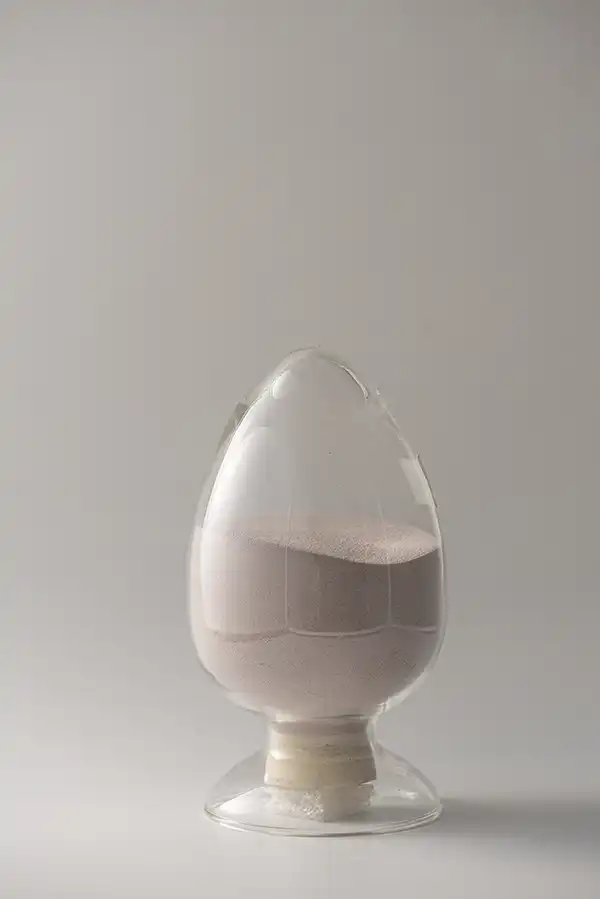

Glass Powder

Product Features: Glass powder is produced through the mechanical crushing and grinding of waste glass, resulting in a fine, granular material.

Particle Size Range: 75μm~180μm

Chemical Composition: Primarily silica (SiO2) with trace oxides

Color: Variable, based on source glass

After-sales service: Providing timely and high-quality worldwide services

Product Details

Glass powder is a finely ground material derived from recycled glass, offering a versatile solution for a wide range of industrial applications. With its unique properties, It serves as a sustainable alternative for various manufacturing processes.It is produced through the mechanical crushing and grinding of waste glass, resulting in a fine, granular material. This eco-friendly approach transforms discarded glass into a valuable resource, contributing to environmental sustainability and resource conservation. The powdered form allows for seamless integration into diverse production processes, enhancing both performance and sustainability.

Performance Parameters

|

Parameter |

Value |

|

Particle Size Range |

75μm~180μm |

|

Chemical Composition |

Primarily silica (SiO2) with trace oxides |

|

Color |

Variable, based on source glass |

Features and Advantages

Features:

Finely Ground Surface: It is created through the mechanical pulverizing and crushing of squander glass, coming about in a finely ground fabric with steady molecule estimate dispersion. This fine surface permits for uniform blending and integration into different fabricating processes.

Eco-Friendly Generation: Glass powder is inferred from reused glass, making it an ecologically feasible elective to virgin materials. The generation prepare includes the reuse of squander glass, decreasing the request for crude materials and minimizing squander sent to landfills.

Versatility: It offers flexibility in a wide run of mechanical applications due to its interesting properties. It can be utilized as a utilitarian added substance, filler, or crude fabric in businesses such as development, ceramics, coatings, plastics, composites, and more.

Advantages:

Resource Preservation: By utilizing reused glass as a crude fabric, It contributes to asset preservation by lessening the require for extraction of virgin materials. This makes a difference protect characteristic assets and decreases the natural affect of mechanical processes.

Waste Decrease: The generation of it makes a difference occupy squander glass from landfills, lessening the volume of squander and moderating natural contamination. This squander diminishment procedure advances maintainable squander administration hones and underpins circular economy principles.

Cost-Effective Arrangement: It offers a cost-effective elective to conventional materials in numerous mechanical applications. Reused glass is regularly accessible at a lower taken a toll compared to virgin materials, giving taken a toll investment funds for producers without compromising on quality.

Application Areas

Construction Materials: Glass powder is used as a partial replacement for cement in concrete and mortar formulations. It enhances the strength, durability, and chemical resistance of concrete, making it suitable for applications in infrastructure projects, building construction, and precast concrete products.

Ceramics and Glass Manufacturing: It is utilized as a raw material in the production of ceramic tiles, glass ceramics, pottery, and glassware. It serves as a fluxing agent, imparting desirable properties such as gloss, color, and thermal stability to ceramic and glass products.

Coatings and Paints: It is incorporated into coatings, paints, and sealants to improve adhesion, abrasion resistance, and UV stability. It enhances the performance and durability of protective coatings used in architectural, automotive, marine, and industrial applications.

Plastics and Composites: It is added to plastic and composite materials to enhance mechanical strength, dimensional stability, and heat resistance. It is used in the manufacturing of fiberglass-reinforced plastics (FRP), composite panels, automotive parts, and electronic enclosures.

|

|

|

|

FAQ

Q:What industries use it?

A:Glass powder finds application in various industries, including construction, ceramics, glass manufacturing, coatings and paints, plastics and composites, metal casting and foundry, abrasive and polishing compounds, environmental remediation, and art and craft supplies.

Q:How is it incorporated into manufacturing processes?

A:It can be added to formulations as a functional additive, filler, or raw material. It is mixed with other materials such as cement, ceramics, plastics, resins, and coatings to enhance performance, properties, and sustainability in manufacturing processes.

Q:Is it safe to use?

A:It is generally considered safe to use in industrial applications when handled properly according to manufacturer guidelines. However, precautions should be taken to minimize inhalation of fine particles and skin contact during handling and processing.

In conclusion

TJNE is a professional manufacturer and supplier of it, providing strong technical expertise, comprehensive after-sales service, certification and testing reports, fast delivery, secure packaging, and testing support. If you are seeking high-quality glass powder for your specific applications, we welcome you to contact yangbo@tjanode.com for tailored solutions.